Smart Production: How Audi Is Designing the Production of the Future

- Cycle-independent modular assembly simplifies work with high product variability

- Virtual inspection of surfaces serves as a digital interface between design, technical development, and production

- Robot dog named Spot supports 3D scanning in production halls

- VR makes globally networked production planning possible in the virtual world

Audi is setting up fully networked, highly efficient, and sustainable production. The goal is to design a resilient, agile, and flexible value chain to meet future challenges successfully. These include a growing diversity of variants, the transition to electromobility, the increasingly volatile supply situation, and political uncertainties. “We’re using synergies and looking at production as a whole – from the worker to the fully automated cycle,” says Gerd Walker, Member of the Board of Management for Production and Logistics. “We’re digitizing specifically within the framework of an open innovation culture. We’re ensuring efficient value creation and making it possible to utilize resources and capacities flexibly and efficiently.”

What advantages does modular assembly have over assembly line production?

The assembly line has set the pace in automotive production for over a century. Now it is increasingly reaching its limits. Numerous derivatives and individualization options are making products more and more varied. In a rigid, sequential process, that complexity is more and more difficult to master. “Modular assembly is one of our answers to future challenges,” says Gerd Walker. “We’re using digital technologies specifically to our employees’ advantage while obtaining a more flexible and efficient assembly process.” In the Audi Production Lab, project manager Wolfgang Kern’s team is preparing modular assembly for mass production.

Audi is initially implementing the concept in interior door panel pre-assembly in the Ingolstadt plant. In the test operation, work no longer follows a uniform sequence. Instead, it meets particular needs. Automated guided vehicles (AGVs) bring door panels right to the station where the components are assembled. “By reducing production time through an orientation toward value creation and self-guidance, we can increase productivity by up to 20 percent in some cases,” Kern says. In addition, we can link the modular assembly to specific production steps. For example, now, a single worker can install complete sun blinds. That used to require two or three workers due to the preset processing times in an assembly line. Another major advantage of the flexible system: Audi can employ people who can no longer work on the line due to physical limitations. The series pilots are producing valuable insights and allowing engineers to derive serial applications. The next step for Project Manager Kern and his team is to integrate modular assembly at a larger scale into pre-assembly.

In terms of production, how is Audi using virtual technologies to influence design and development processes?

A model’s various designs and equipment variants can be examined quickly and efficiently in different environments and lighting conditions using virtual representations. One urgent goal is to move the design into production with the least number of possible cuts and get it on the road for customers. To that end, experts look at design drafts from a model’s early development phase up to the tools’ release to see if they can reproduce them in serial production. Final approval of the cars’ surfaces comes in what is known as data control milestones.

The most important tools for doing that are big screens, known as powerwalls, which allow us to depict a car in its original size. In combination with the visualization cluster – a computer cluster with a total of 26,000 CPUs – cars can be presented realistically and with physically based light, shadow, and reflection calculations. That process is the basis for the virtual decision-making process. Along with the powerwall visualization, Audi is increasingly using head-mounted displays. The major advantage of that method is that it allows experts to experience virtual models from the customer’s perspective. Because this special virtual reality system can run on standard hardware and software, it can be installed quickly and flexibly. Many people can use it, and it can easily be recreated at other locations around the world.

This technology is also used in tolerance management. That way, Audi ensures it can build a particular model to spec from both a constructive and a qualitative perspective. With 3D simulations of the body, the effects of component and assembly tolerances can be foreseen in the vehicle's image. The simulation results are then realistically visualized using virtual reality. That way, the experts from Audi Production can influence the design and development process regardless of time and place at almost no additional cost and, for the first time, from the production facilities.

What are the essential benefits of virtual assembly planning in smart production?

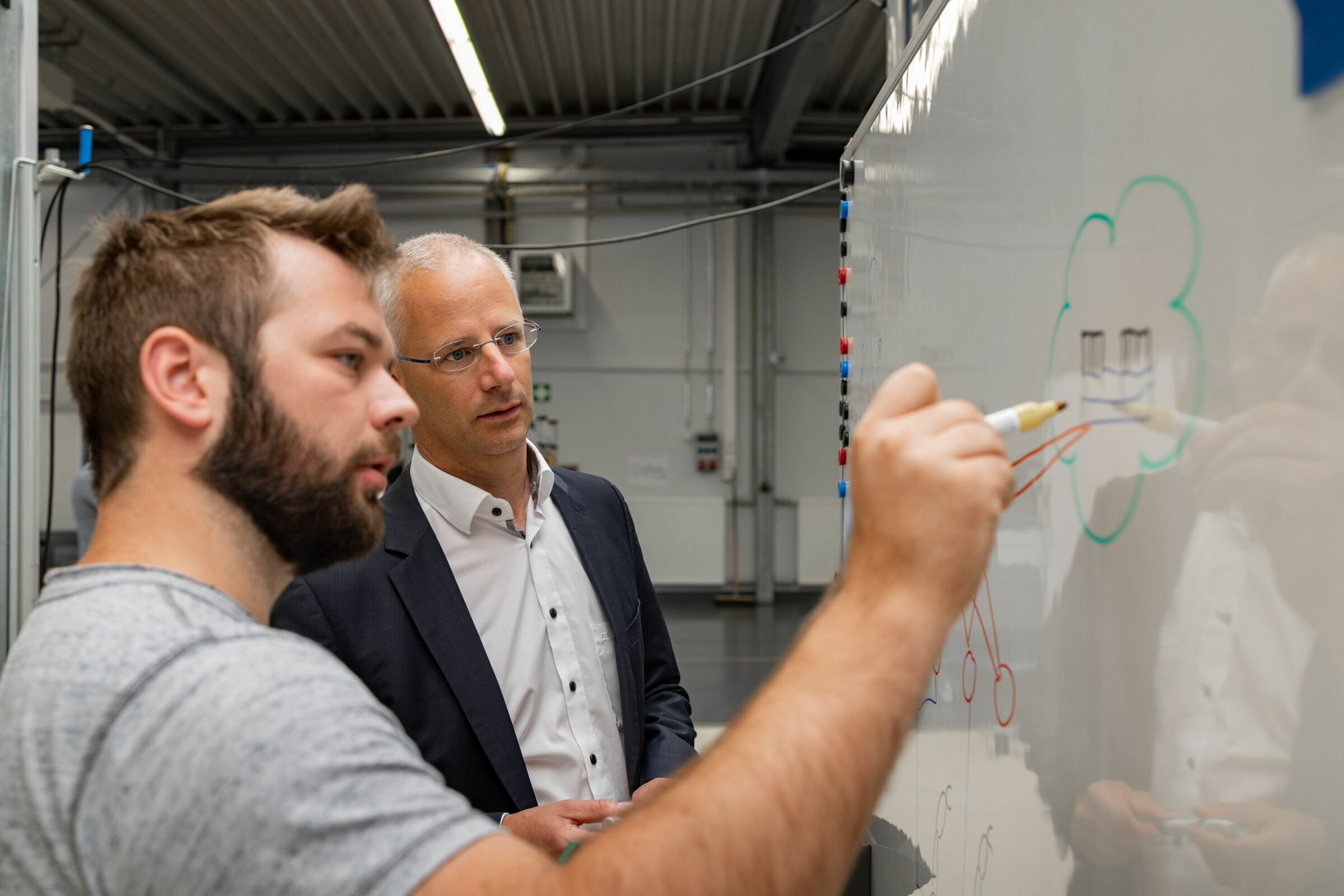

Virtual assembly planning not only saves material resources but also makes innovative, flexible collaboration possible across different locations. It eliminates the need to build prototypes in the planning process. A scanning process generates three-dimensional point clouds that can be used to virtually reverse engineer machines and infrastructure. The software is based on artificial intelligence and machine learning. It makes it possible for employees at Audi to navigate through assembly lines virtually. Volkswagen’s Industrial Cloud gives them an efficient tool that allows them, for example, to compare locations and use appropriate solutions from other production lines in their planning.

Right now, Audi is working with NavVis to test Spot the robot dog so they can do the 3D scans as efficiently as possible. Around four million square meters (43 million sq. ft.) and 13 plants have been involved since site digitalization started in 2017. Scanning 100,000 square meters (1,076,391 sq. ft.) – for instance, in Audi A6 production in Neckarsulm – takes about three weeks in single-shift operation. The scans can only be done at night or on weekends. On top of that, structural obstacles like steps and doors make scanning work more difficult.

By contrast, Spot the robot dog can do that scanning in 48 hours and figure out his route autonomously. Audi has been testing Spot intensively since December 2021. “The test results are extremely promising and can be updated regularly,” says project manager André Bongartz. “Input data are constantly coming in, and we can use it in planning for new car models.” Any range of 3D scans can be integrated into the virtual images, which Andrés Kohler’s team is responsible for. “Merging all the planning data in our digital twin has given us a holistic look at our future production plans years ahead of time,” Kohler explains. Like in a real factory, it includes the shop floor, conveyor technology, tools, shelving, and containers alongside the new Audi model.

Assembly sequences and logistical aspects are largely designed and optimized by interdisciplinary teams in what is known as 3D process workshops. Thanks to the digital twin and an in-house VR solution, Audi exploits the benefits of digitalization and visualization. These include component data that are updated daily and a view of various car variants. “Above all, we look at production in terms of what it will look like later on as a whole,” Andrés Kohler explains. He emphasizes that collaboration remains a core element: “I’m always fascinated all over again the moment we put on the VR glasses and meet our colleagues as avatars in the virtual world. First, we build our new Audi there or look at a computer-generated avatar and how it applies as a real-time simulation. And when necessary, while we're in there together, we discuss and optimize the sequences and the workplace environment, like how to set up materials of what tools are needed.”

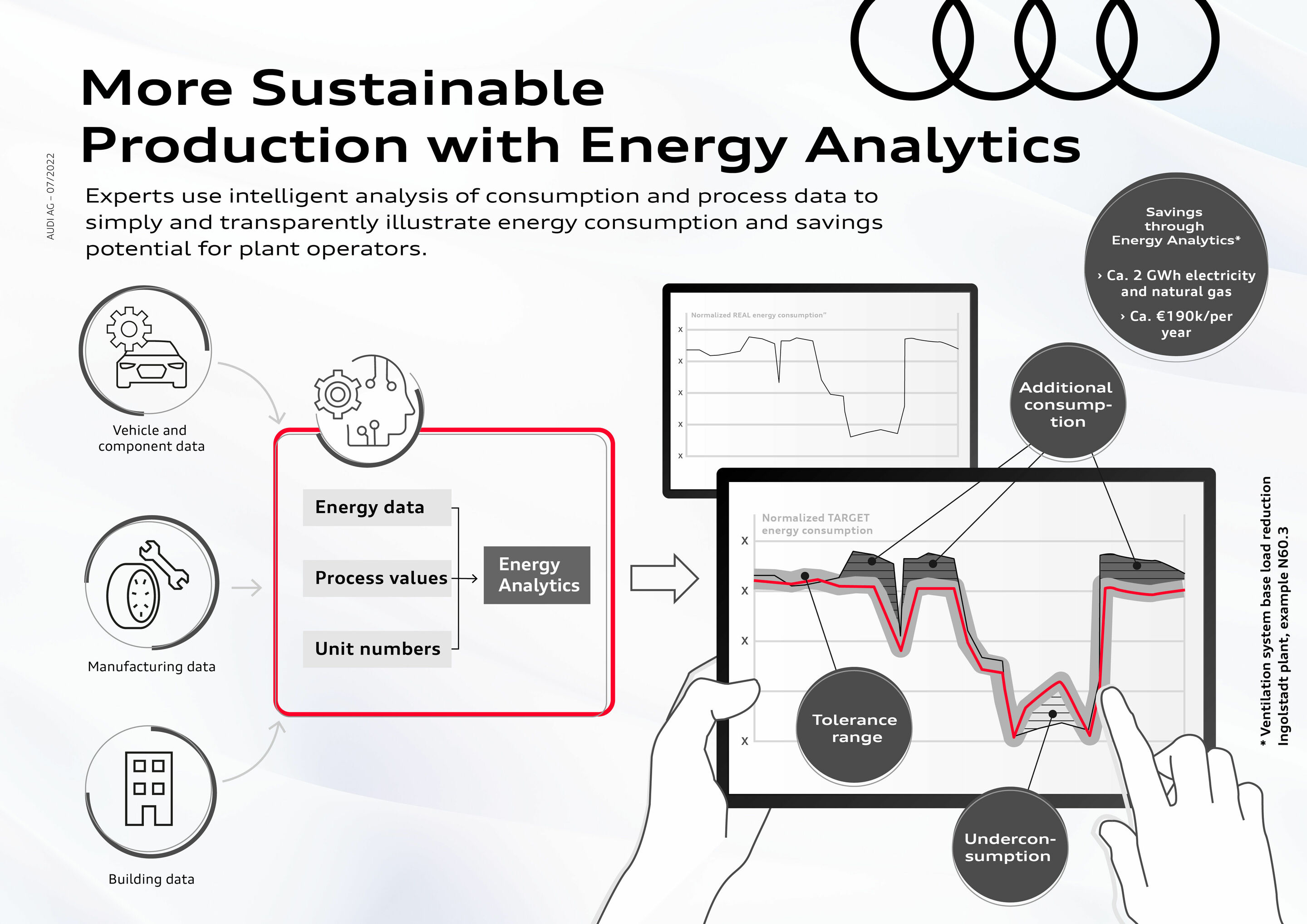

How is Audi able to save energy in production?

The energy that the Audi site in Ingolstadt consumes in a year is equivalent to the amount the entire city uses. Data and data analysis are essential tools for saving energy. The Energy Analytics tool that Audi developed in-house helps make manufacturing sustainable while conserving resources. It enables us to point out high energy consumption in production and during non-production times. First, experts collect data from various sources in a consistent data format. For example, they gather data from completed vehicles and components, energy data from spray booths or welding guns, and information on consumption from lighting and ventilation in the buildings. In the next step, they make energy consumption transparent for the energy officers, who can use it to analyze their energy use. If energy needs exceed previously defined tolerance limits, they can assess the causes and take steps to reduce consumption during production or even reduce the base load in production areas. In 2021, Audi was able to use Energy Analytics and process improvements to save about 37,000 MWh at its Ingolstadt site.

How and where is Audi using artificial intelligence in production?

Artificial intelligence and machine learning are core technologies in Audi’s digital transformation and modern production. An AI algorithm in the Ingolstadt press shop helps identify flaws in components. That procedure is supported by software based on an artificial neural network. The software itself identifies the smallest flaws and reliably marks them. The solution is based on deep learning, a special kind of machine learning that can work with unstructured and high-dimensional data volumes. The team used several million test patterns to train the artificial neural network over months. That database comprises several terabytes of these images from presses at Audi sites and several Volkswagen sites.

In another pilot project, Audi uses artificial intelligence to check the quality of spot welds in high-volume production at its Neckarsulm site. It takes about 5,300 weld spots to connect the components in the body of an Audi A6 with one another. Until now, production staff have used randomized ultrasound analyses to monitor the quality of resistance spot welding (abbreviated WPS in German). As part of the WPS Analytics pilot project, experts use artificial intelligence (AI) to detect quality anomalies automatically in real-time. Currently, the algorithm, dashboard, and deep quality analysis application are all used to construct the body of the A6 and A7. It is a blueprint for other applications in networked production.

What’s behind the Edge Cloud 4 Production concept?

With the local server solution Edge Cloud 4 Production, Audi is initiating a paradigm shift in factory automation. After successful testing in the Audi Production Lab (P-Lab), three local servers will take over worker support in the Böllinger Höfe. In production in Neckarsulm, the Audi e-tron GT quattro and the R8 share an assembly line. The small-scale series produced there are particularly well suited for testing projects from the P-Lab and trying things out for large-scale series. Audi wants to be the first manufacturer in the world to turn to these kinds of centralized server solutions in cycle-dependent production. If the server infrastructure continues to operate reliably, Audi wants to roll out this automation technology – the only one of its kind in the world – for serial production throughout the group.

With the Edge Cloud 4 Production, a few centralized and local servers will take on the work of countless expensive industrial PCs. The server solution makes it possible to level out the virtualized clients across the total number of them – a far more efficient use of resources. Production will be economized, particularly where software rollouts, operating system changes, and IT-related expenses are concerned. “What we’re doing here is a revolution,” says Gerd Walker, Member of the Board of Management of AUDI AG Production and Logistics. “We used to have to buy hardware when we wanted to introduce new functions. With Edge Cloud 4 Production, we only buy applications in the form of software. That is the crucial step toward IT-based production.”

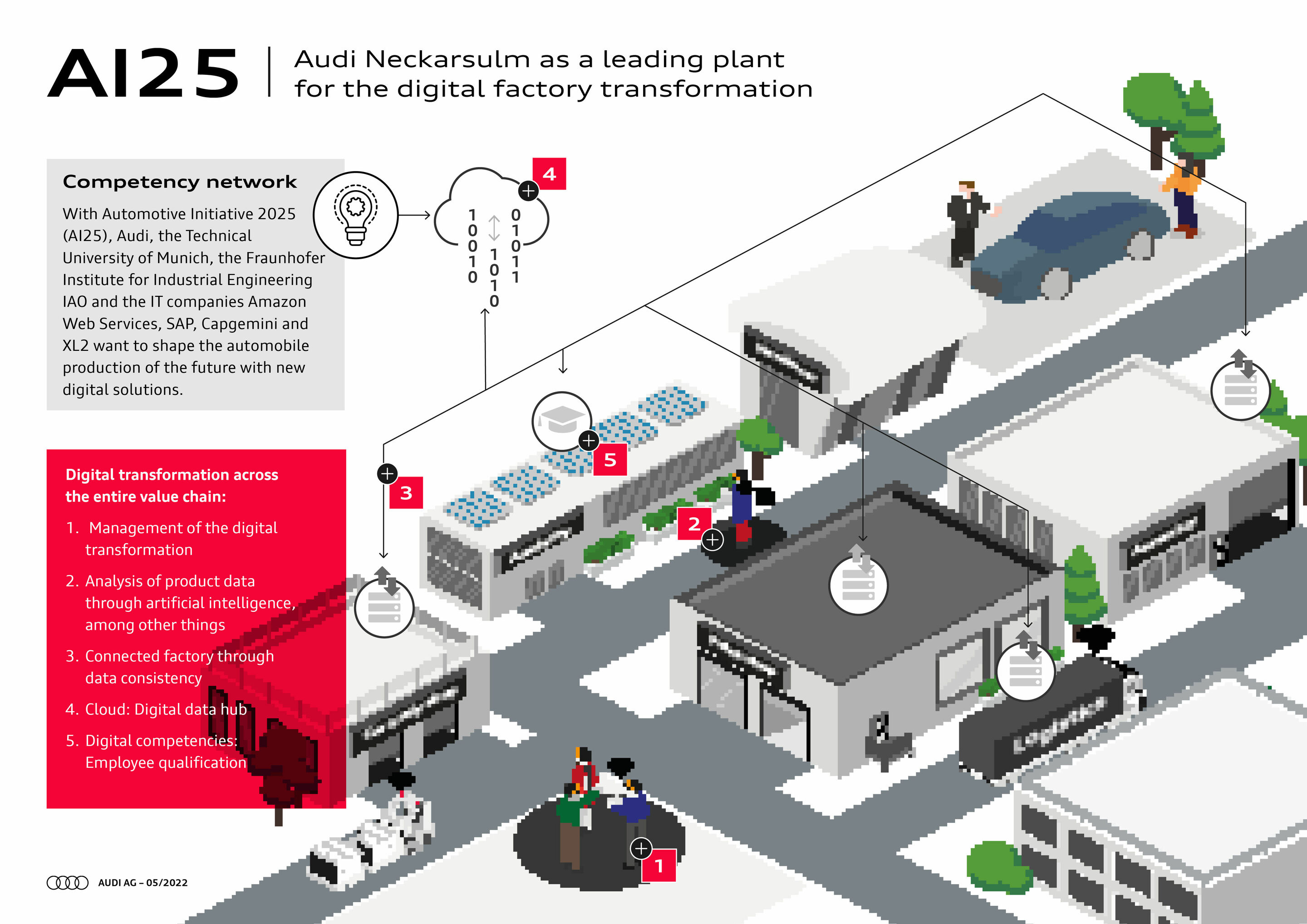

Where do new ideas for future digital production come from?

Audi works closely with the Technical University of Munich and the Fraunhofer Institute for Industrial Engineering and Organization ((IAO) on digitization at the educational campus in Heilbronn. Audi’s “Automotive Initiative 2025” (AI25) aims to establish the world’s leading network of expertise for digital factory transformation and innovation. AI25 sees itself as an idea generator and an important component of the transition to digital. The Audi site in Neckarsulm will play a pivotal role as a pilot factory for the digital transformation of the Volkswagen Group. The real-life laboratory of the Böllinger Höfe plays a vital role in that. Additionally, Audi uses its Production Lab in Gaimersheim to identify new and innovative technologies and reliably integrate them into production sequences. Experts test new solutions’ applicability for series production in close dialog with users.