Production and Logistics

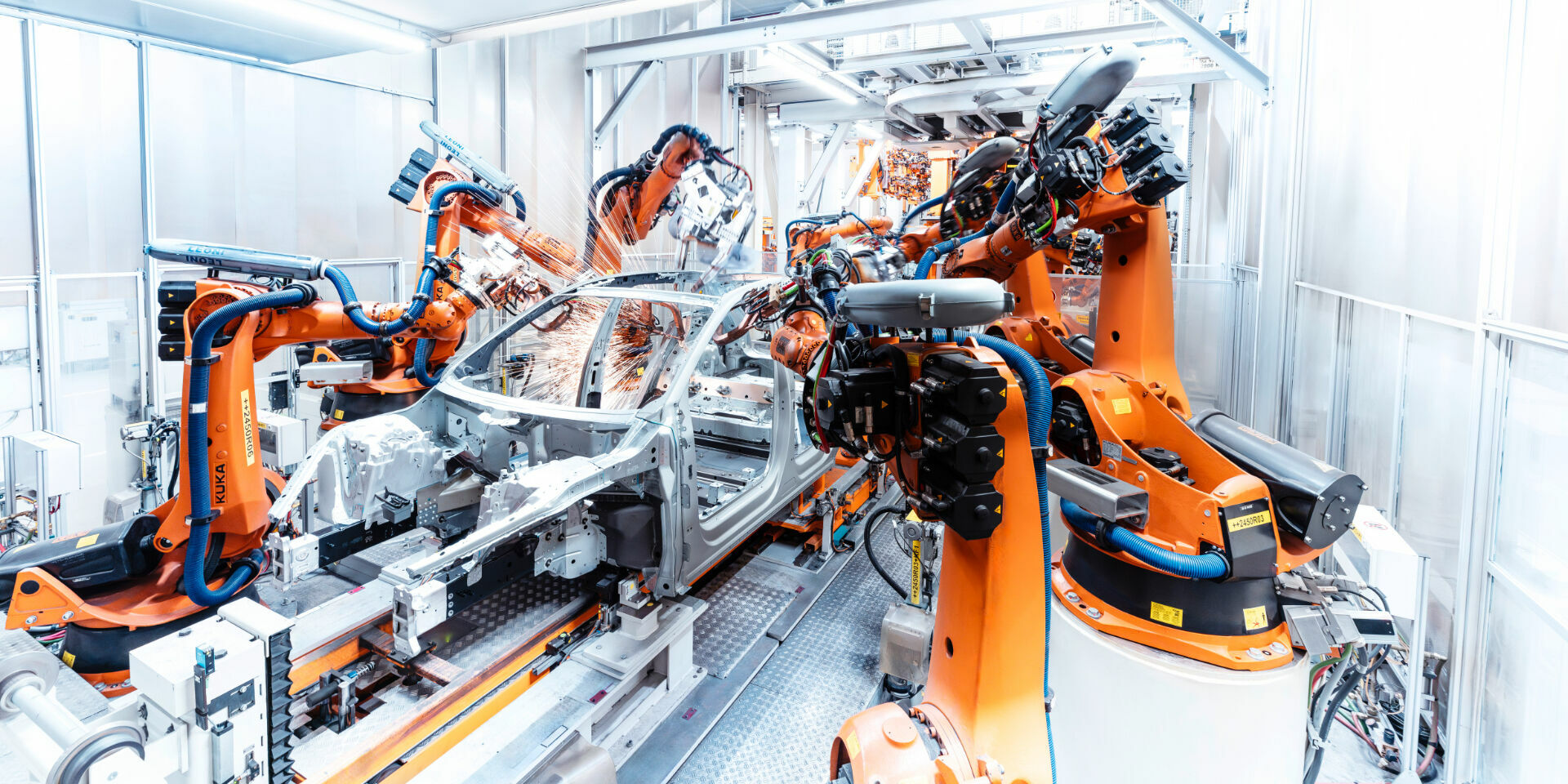

Audi stands for sustainable, efficient, and flexible production. To achieve this goal, Audi relies on its global production network while, at the same time, transforming its highly qualified staff and leveraging digital technologies in the manufacturing process. To further reduce the environmental impact in the area of production and logistics, Audi is pursuing its central goal of making all Audi production sites worldwide net carbon neutral* by 2025.

MediaInfos

Press kit

-

Digital production: More efficient. More human. Future-ready.

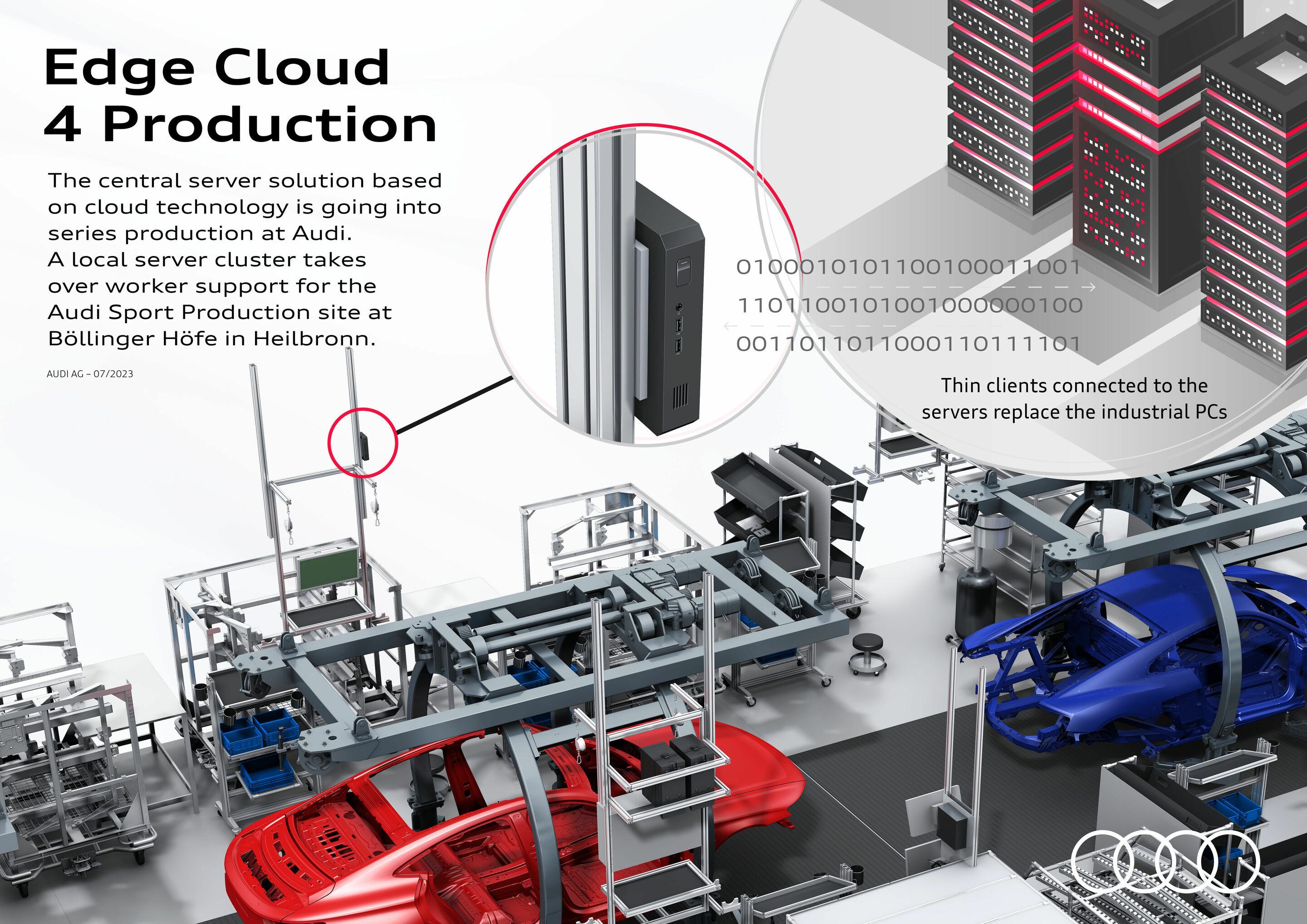

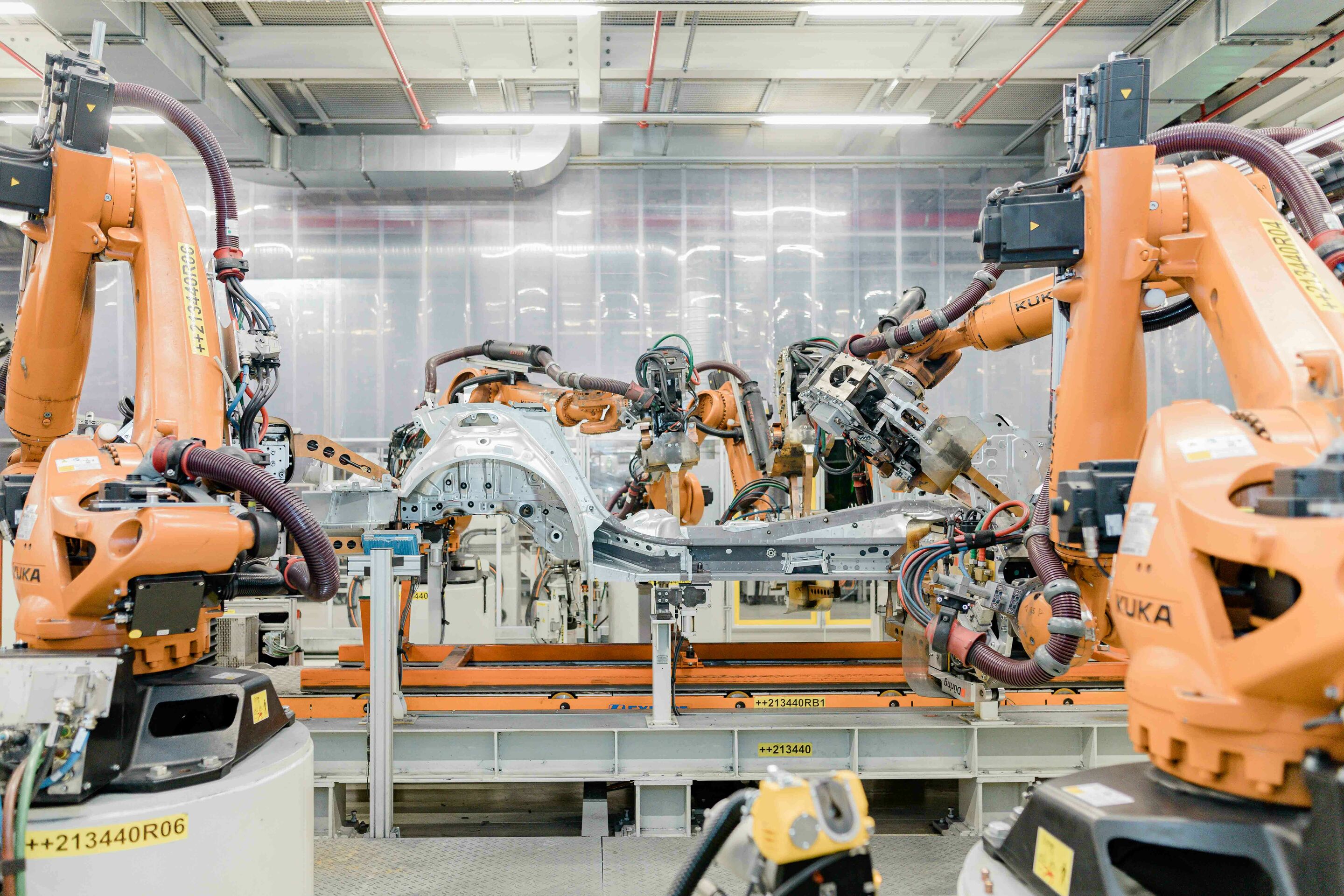

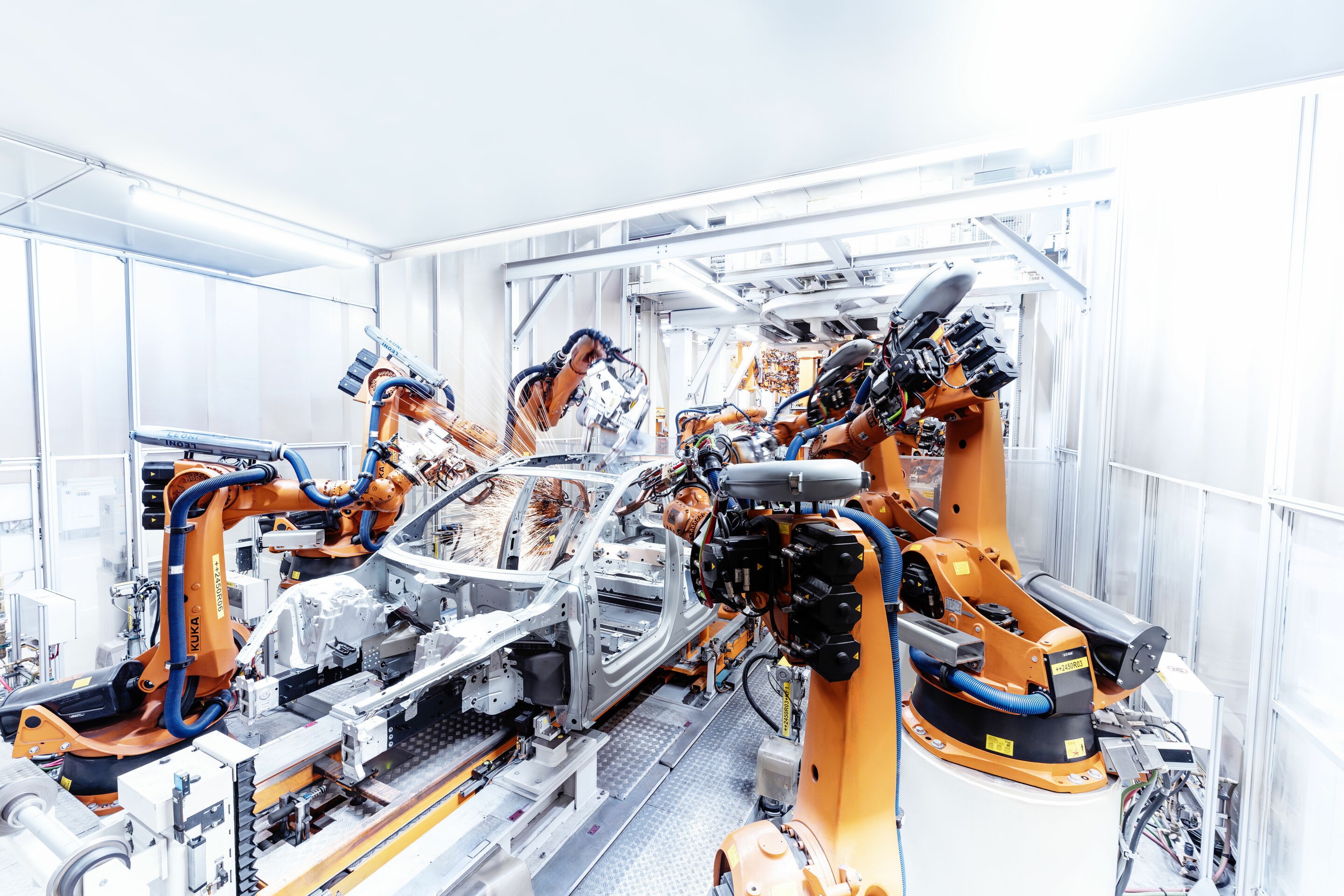

Audi is driving the transition to fully connected, highly efficient and sustainable production through digital innovation. New technologies such as virtual planning and the Edge Cloud 4 Production are enabling a paradigm shift in factory automation. Audi approaches production holistically – from employees to automated cycles – and laying the foundation for future-proof, flexible, and resilient value creation.

Audi is driving the transition to fully connected, highly efficient and sustainable production through digital innovation. New technologies such as virtual planning and the Edge Cloud 4 Production are enabling a paradigm shift in factory automation. Audi approaches production holistically – from employees to automated cycles – and laying the foundation for future-proof, flexible, and resilient value creation.