Audi at the Neckarsulm site

Audi at the Neckarsulm site

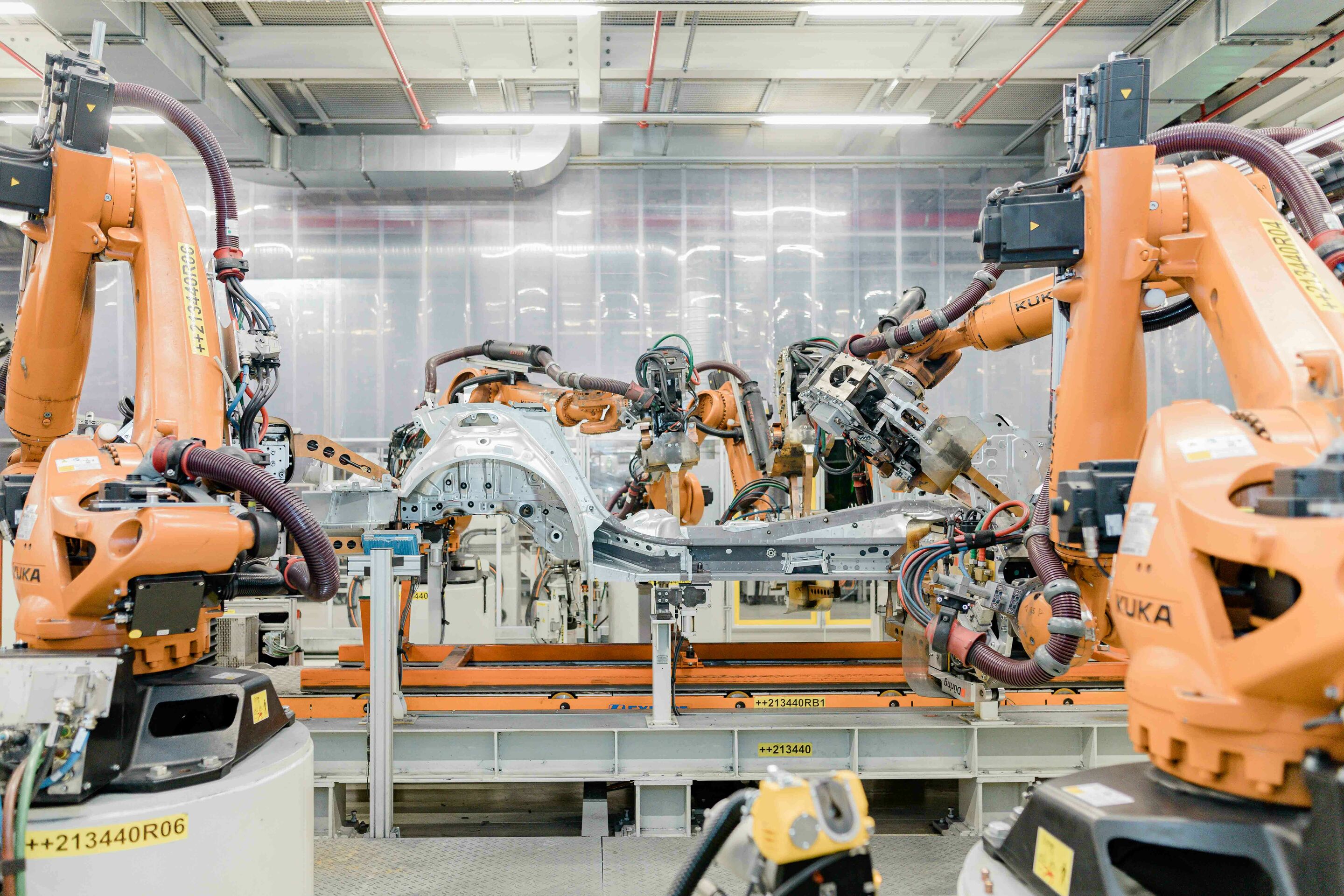

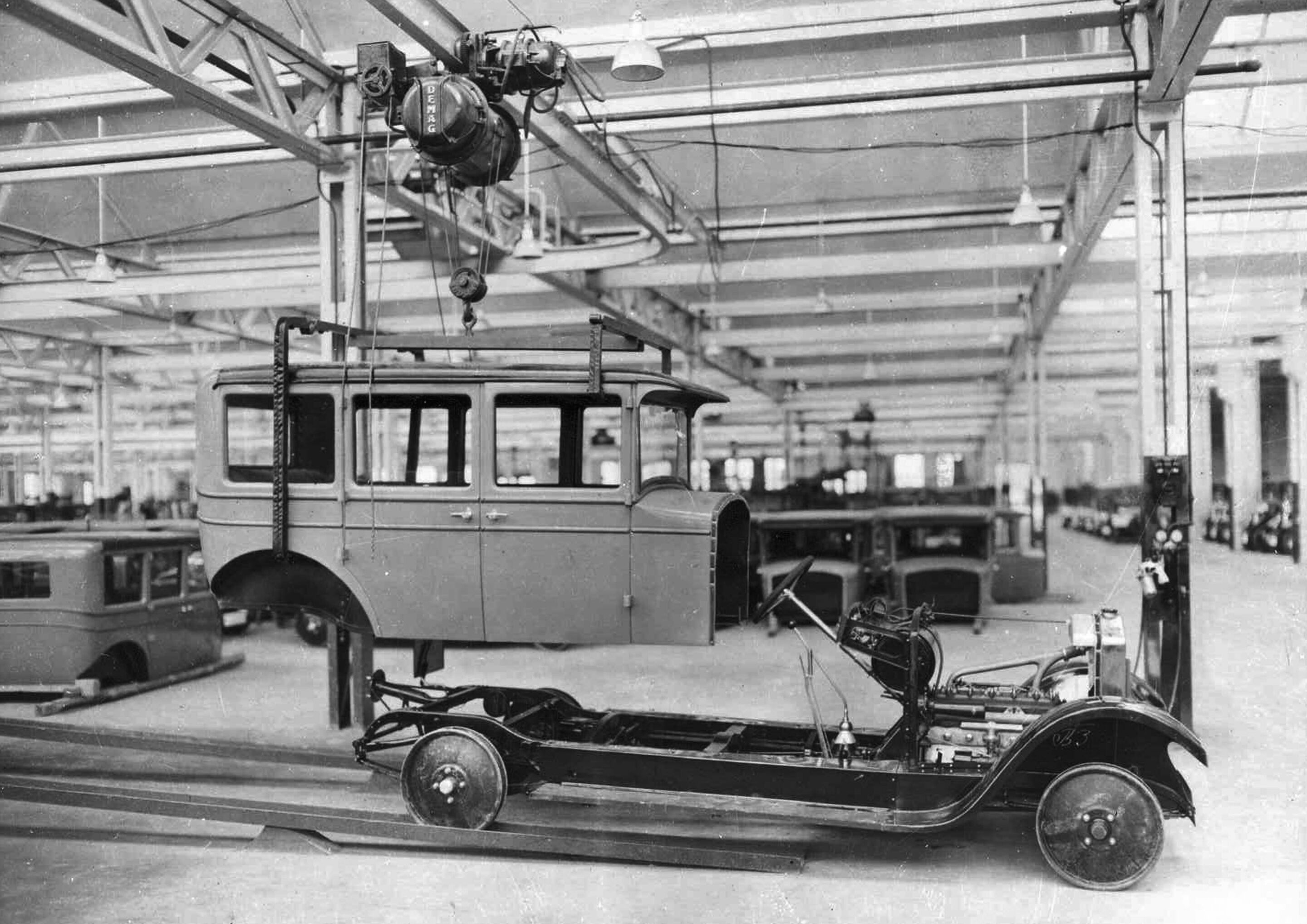

The Audi Neckarsulm site has been manufacturing cars for over 100 years. Driven by innovative ideas, passion, and the pursuit of perfection, the location has developed from its beginnings as a knitting machine workshop to a modern car manufacturing site.

AUDI AG is one of the largest employers in the Heilbronn-Franken economic region. 15,515 people work here for the Mobility of the Future.

Current model series at location: Audi A5, Audi A6, Audi A8, Audi e-tron GT

Recent MediaInfos

Audi Forum Neckarsulm

The Audi Forum Neckarsulm is an established event location and provides new impetus in the region through various event formats. From small close-up concerts to technology workshops for children to large pop concerts – with a mixture of proven and innovative concepts, the Audi Forum inspires its guests repeatedly.