The comfort features in the Audi Q8 e-tron are typical of the brand’s luxury-class models. The panoramic glass roof, for example, opens and closes electrically and enhances its light and spacious appearance. The light-tight sunblinds are just as convenient to operate: when open, the two-part panorama glass roof improves the interior climate through efficient ventilation and an integrated wind deflector reduces wind noise.

As an alternative to the standard two-zone automatic air conditioning, Audi offers four-zone automatic air conditioning and the air quality package. It includes an ionizer and fragrancing that customers can adjust in several stages for first-class air quality.

A three-stage ventilation system makes for comfortable seating, even at hot outside temperatures. The system is now available for standard leather seats with high-detail perforation with numerous adjustment options. In addition to pneumatic adjustment of the seats and backrests, a massage function is available upon request. Ten pneumatic cushions relax the occupant’s back muscles in seven selectable programs and three intensities, increasing seating comfort on long trips in particular.

In the dark, the optional ambient lighting package, with its white LED light, stages the interior to great effect, gently illuminating surfaces such as doors and the instrument panel, making them appear to float. The ambient light package plus offers a further enhancement with six predefined color profiles and extensive contour lights in up to 30 colors which precisely trace the lines of the interior.

Progressive elegance

The interior of the Audi Q8 e-tron stands for performance, intelligence, lightness, and unified design – characteristics that are expressed in many of the vehicle’s details; design and technology form a single unit. A generous arc wrap-around envelops the instrument panel with pronounced horizontal lines as far round as the sculptural door panels. It harmoniously integrates the displays of the optional virtual exterior mirrors as well as the hood above the Audi virtual cockpit, whose sleek display stands visually free in space. The cockpit has a strong driver bias, and the two MMI touch response displays are angled in the driver’s direction. When switched off, the upper one of these blends almost invisibly into the large black panel surface, in contrast, the lower display is incorporated into the broad center console. Options include the multifunction buttons on its edge and the control element for the lighting functions in a black panel design with touch response technology.

Both touch displays show all images and information on a black background and as a general design concept, the graphical user interfaces have been deliberately reduced and clearly structured so that the information can be assimilated quickly.

New highlight: the stitching package in red

Customers can choose from several colors and equipment packages for the interior of the

Audi Q8 e-tron. Two interior lines are available: the base version with comfortable seats and decorative inlays in graphite gray, and the S line version with more highly contoured sports seats and contrast stitching, stainless steel pedals, a comfortable center armrest, and decorative inlays in matte brushed aluminum. The choice of seat upholstery begins with fabric and ranges through the sustainable microfiber material Dinamica to premium Valcona leather with a very fine and pleasantly warm surface. There is optional contrasting stitching on the seats, center armrest, and armrests, and at the front, the floor mats in the S model in both variants have a rhombus S badge.

A new highlight is the Audi Sport stitching package in red, adding high-end accents to the sports seats, steering wheel, knee pad, and door armrests with colored stitching. Edged in red, the seat belts are another interior highlight.

All equipment versions include decorative inlays in a choice of open-pore wood veneers such as grained ash or sycamore wood or aluminum; for the first time, the S line equipment package and the Edition S line also offers a carbon structure. New additions to the range include light brown walnut wood and a sustainable technical fabric made in part from recycled PET bottles.

Recyclates and resource-efficient materials

The Audi Q8 e-tron will reach customers in Europe and the United States as a certified, net carbon-neutral1 car. To help conserve resources, Audi is using recyclates – processed plastics derived from a recycling process – in some components of the Audi Q8 e-tron. The interior of the Audi Q8 e-tron uses recyclates for carpets as well as in insulation and damping materials with the purpose to not only to use less resources, but also close a material loop for reasons of economy and efficiency.

The decorative inlay (the tech layer above the display) is available with a novel, anthracite tech fabric made from up to 60% recycled PET bottles. In the S line equipment package, the sports seats are upholstered with Dinamica microfiber material and artificial leather – consisting of up to 45 percent polyester fibers, Dinamica still looks and feels like suede and the fibers used are obtained from recycled PET bottles, old textiles, or residual fibers. In contrast to the previous microfiber quality, the production of Dinamica is also solvent-free – a further contribution to environmental protection.

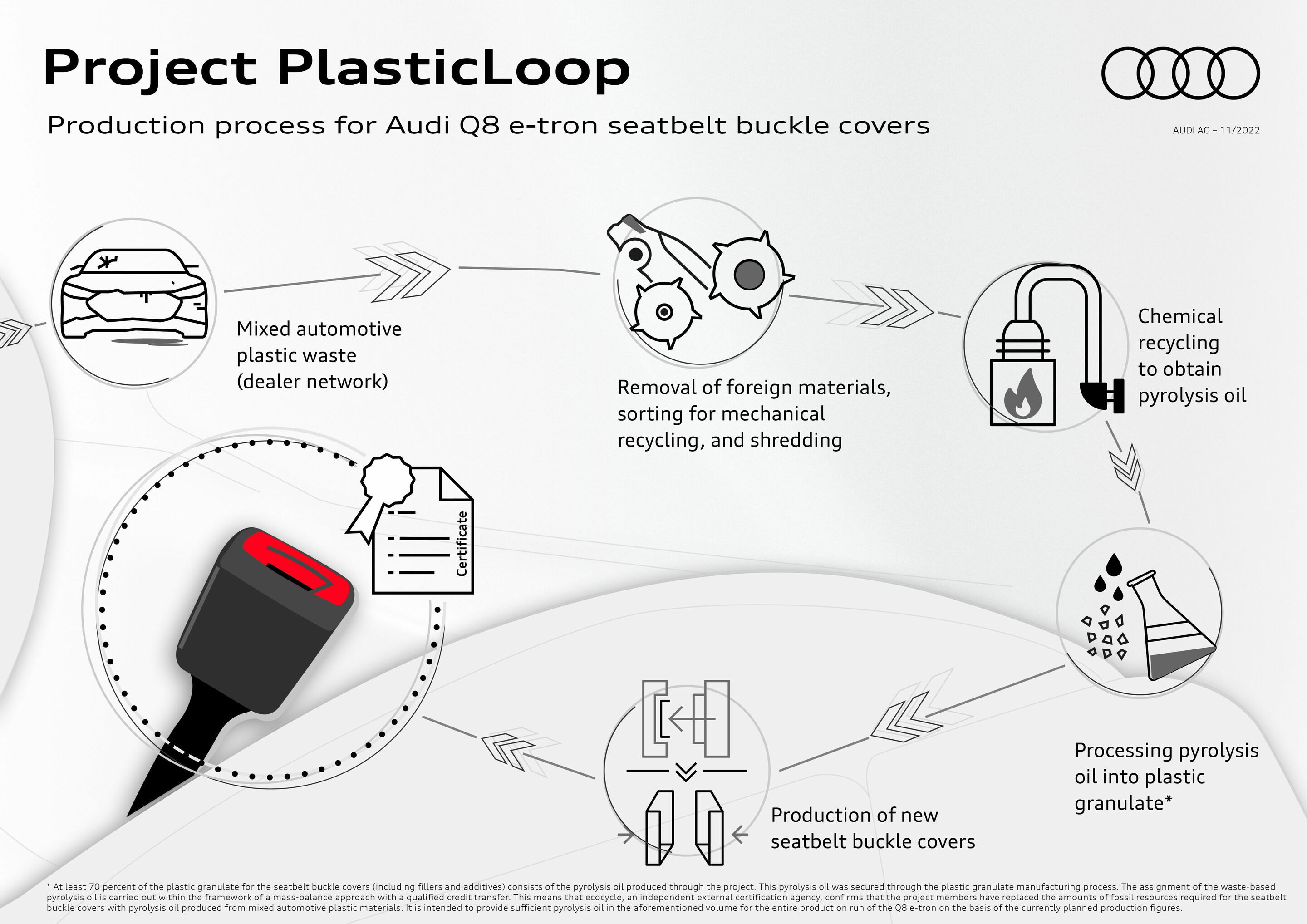

Pilot project: Seatbelt buckle covers made from an innovative recycling process

The Q8 e-tron also marks the first time that safety-relevant components are used which have been produced in part from mixed automotive plastic waste via a chemical recycling process: the plastic covers of seatbelt buckles. As part of the PlasticLoop project, Audi and plastics manufacturer LyondellBasell took the findings from a pilot project and established an innovative process that will employ chemical recycling for the first time to reuse mixed automotive plastic waste for the series production of the Audi Q8 e-tron. For this process, Audi has joined forces with LyondellBasell to first dismantle plastic components from customer vehicles that are beyond repair, then cleanse the components of foreign materials such as metal clips, before being shredded and processed via chemical recycling into pyrolysis oil. This is then used as a raw material for the production of new plastics using a mass-balance2 approach.

The plastic granulate obtained is used for the production of the Q8 e-tron seatbelt buckle covers. Audi and its project partners have succeeded in cycling another material stream, which today is usually only suitable for energy recovery, allowing Audi to use fossil raw materials for longer and reduce the purchase of additional primary materials for the Q8 e-tron accordingly. The components made from pyrolysis oil have the same high quality and technical properties as virgin materials.

Chemical recycling offers a good alternative to energy recovery and thereby complements mechanical processing, where recycled single-variety plastics are primarily used. “At Audi, our goal is to use secondary materials wherever it is technically possible and makes ecological and economic sense,” says Philipp Eder, Project Manager for Circular Economy in the Supply Chain at Audi. The PlasticLoop project is part of Audi’s circular economy strategy and serves as a good example for cross-industry cooperation within the Audi supply chain. Findings from the project also flow into product development for future vehicle projects via Audi’s “design for recycling” approach.

1 Audi understands net-zero carbon emissions to mean a situation in which, after other possible reduction measures have been exhausted, the company offsets the carbon emitted by Audi’s products or activities and/or the carbon emissions that currently cannot be avoided in the supply chain, manufacturing, and recycling of Audi vehicles through voluntary offsetting projects carried out worldwide. In this context, carbon emissions generated during a vehicle’s utilization stage, i.e., from the time it is delivered to the customer, are not considered.

2 At least 70 percent of the plastic granulate for the seatbelt buckle covers (including fillers and additives) consists of the pyrolysis oil produced through the project. This pyrolysis oil was secured through the plastic granulate manufacturing process. The assignment of the waste-based pyrolysis oil is carried out within the framework of a mass-balance approach with a qualified credit transfer. This means that ecocycle, an independent external certification agency, confirms that the project members have replaced the amounts of fossil resources required for the seatbelt buckle covers with pyrolysis oil produced from mixed automotive plastic materials. It is intended to provide sufficient pyrolysis oil in the aforementioned volume for the entire production run of the Q8 e-tron on the basis of the currently planned production figures.

All terms marked in the text are explained in detail in the technology lexicon at www.audi-mediacenter.com/en/technology-lexicon. The equipment, data and prices specified in this document refer to the model range offered in Germany. Subject to change without notice; errors and omissions excepted.