Supply chain

Responsibility for people and the environment: Audi brings its sustainability requirements to the supply chain

How a company operates affects both people and the environment. Audi, therefore, centers its activities around sustainability. These include respecting human rights and adhering to environmental and social standards across the supply chain.

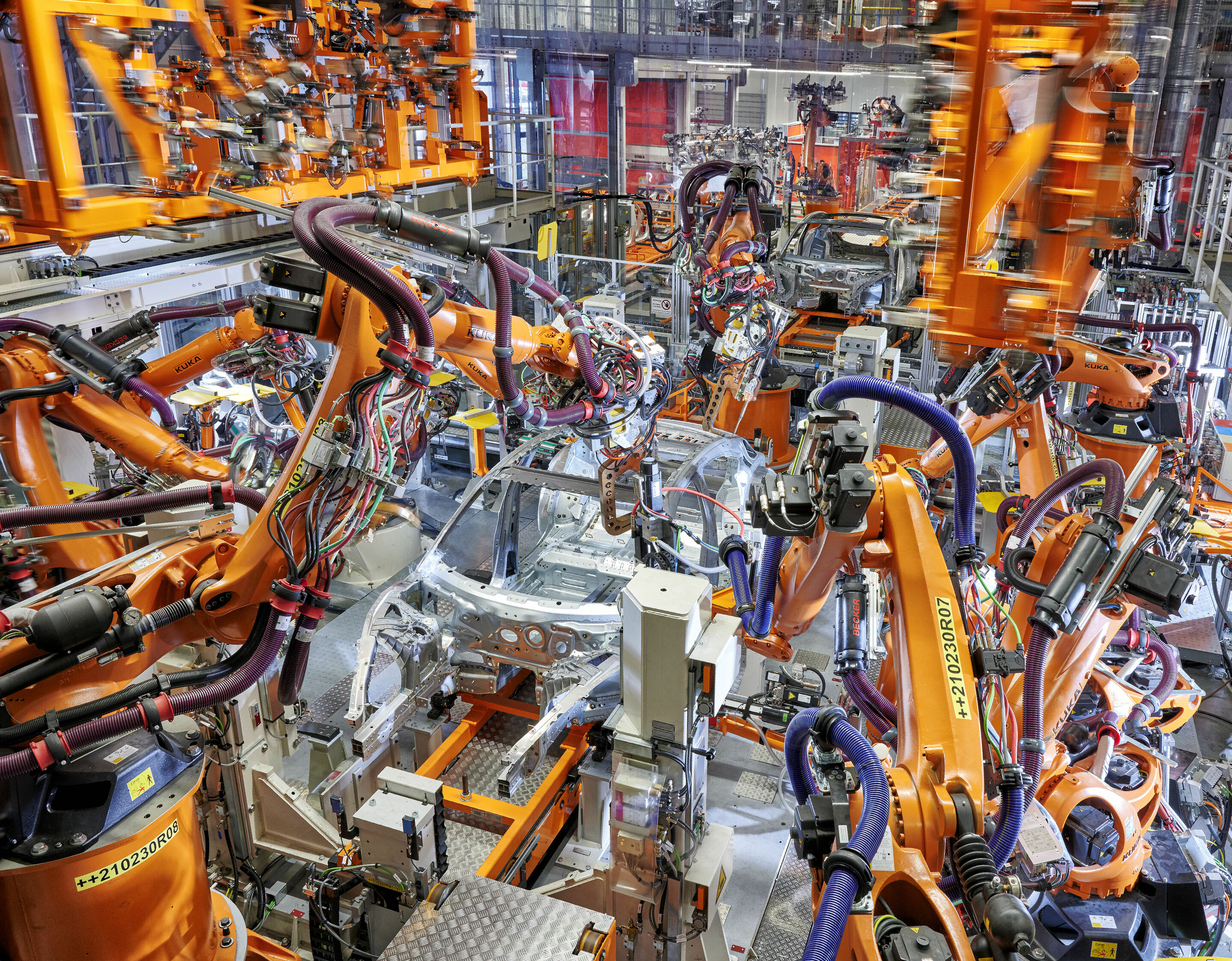

Building an Audi is an involved, elaborate process based on complex supply chains that are as diverse as they are global. The company encounters different cultures, cultural standards, and legal requirements within these supply chains. These give rise to ecological and social risks related to carbon emissions, working conditions, occupational health and safety, and additional social aspects.

Audi’s commitment to more responsible supply chain management has exceeded the legal requirements for years to impact the well-being of people and the environment positively. Moreover, regulations at various political levels have required corporate responsibility throughout the supply chain in recent years. For example, Germany’s Supply Chain Due Diligence Act regulates corporate responsibility for complying with human rights or environmental due diligence in global supply chains; the law was passed in 2023.

Audi follows a human rights strategy to successfully implement the legally required environmental, human rights, and due diligence targets alongside those that Audi has set itself. Strong partner companies along the supply chain are crucial in this pursuit. Sustainable action in complex manufacturing processes is only possible when all partners work together as equals in pursuing the same goal. Therefore, Audi supports its more than 14,000 suppliers from around 60 countries in implementing sustainability into their operations. Its environmental, social, and compliance guidelines, defined in the Code of Conduct for Business Partners, form the basis for collaboration and are integral to risk assessment processes.

People, the environment, innovations

Audi pursues the goal of a more sustainable economy and bases corporate success on compliance and values such as integrity. The company focuses on three fields of action in its supply chain: people, the environment, and innovations.

Since the beginning of 2023, Daniel Patnaik has coordinated and monitored compliance with human rights within the Audi Group and across the supply chain as Human Rights Officer. “We seek to have a positive impact through our business activities and to help improve compliance with human rights globally. We are facing the associated challenges and looking to seize the opportunities along the way,” said Patnaik. “One thing is clear: Wherever people work, not only do they create value, but there are also risks that result in mistakes and violations. Respecting and ensuring human rights in a large company like Audi will never be a done deal; it requires continuous effort.”

Audi develops environmental standards, consistently advocates for better working conditions – for example, when dealing with critical raw materials – and is increasingly integrating new technologies to continuously improve traceability in the supply chain and proactively promote the cooperation of its suppliers.

A sustainability initiative, Act4Impact, also provides a toolbox to enable cooperation in the supply chain. With it, Audi is building a network of suppliers to work together on solutions for a more sustainable supply chain. The Act4Impact Playbook provides comprehensive information on the initiative’s principles and measures and numerous suggestions for its suppliers’ implementation. The program seeks to develop a common understanding, promote ongoing learning, and provide an opportunity for ideas and cooperation to stimulate and kick-start change.

The Volkswagen Group’s Responsible Supply Chain (ReSC) system ensures human rights and environmental due diligence in procurement activities, including Audi or subsidiaries. The system is based on a risk analysis that considers suppliers’ business models, their S-Ratings, external materials such as media reports or data from the whistleblower system, research from studies, NGO reports, and discussions with stakeholders on human rights and environmental risks.

Mandatory ratings

Audi uses various tools to actively shape supply chain sustainability in terms of people, the environment, and innovation. One example here is the sustainability rating or “S-Rating”. This tool helps suppliers evaluate their plants concerning sustainability, the environment, and social well-being regardless of their location and size. In short, Audi uses this procedure to ensure contractual partners comply with the contents of the Code of Conduct for Business Partners. It also lets the company determine the sustainability performance of its suppliers. Since July 2019, it has been a mandatory criterion for awarding contracts across the Group.

The rating uses a self-assessment questionnaire (SAQ). Evaluation is based on the suppliers’ responses. In some cases, on-site checks are also carried out. Audi only works with companies that pass this audit. The S-Rating is mandatory for all companies that employ more than ten people at their site and wish to cooperate with Audi.

The S-Rating is given the same priority as all other contract criteria, such as costs, technological skills, quality, and logistics.

The S-Rating result is divided into three categories: Suppliers with the rating A or B sufficiently meet the requirements of the Volkswagen Group and are thus eligible to receive contracts. If a supplier does not meet the requirements on compliance with sustainability standards (C rating), it is not eligible to receive contracts. This creates a direct incentive for suppliers to improve their sustainability performance.

A systematic approach to raw material supply chains

One of Audi’s goals is to fulfill its human rights due diligence in its raw material supply chains, too. Within the framework of the ReSC system, this is accomplished through the Volkswagen Group’s Raw Materials Due Diligence Management System (RMDDMS), which focuses on concrete measures to identify and minimize risks in upstream supply chains.

An objective analysis prepared through the initiative shows which raw materials in which processing sectors may pose the greatest risks to human rights. For example, the analysis has revealed that for 18 raw materials, including aluminum, cobalt, and leather, there is a particularly high risk of human rights violations and environmental hazards in the extraction and manufacturing processes. A clear system was also established to deal with these findings within the Group. Related measures differ by raw material.

Audi is responsible for developing the Volkswagen Group’s risk mitigation measures and risk analysis for aluminum and copper raw materials. Since 2021, Volkswagen has published annual reports on the status, progress, and targets in its “Responsible Raw Materials Report”.

Building and maintaining alliances

Anchoring sustainability and systematically ensuring human rights in the supply chain requires strong alliances and collaboration with other companies, civil society, and people. Associated measures include Audi’s involvement in the Aluminum Stewardship Initiative (ASI) and the World Economic Forum’s Global Battery Alliance (GBA).

Since the ASI was founded, Audi has helped develop and implement a global standard for more sustainable aluminum. Among other things, this standard requires that mining companies closely follow ecological, social, and governance criteria when extracting the aluminum ore bauxite and reflect them in all operational decisions related to their mines. This requirement is just one reason why representatives of indigenous peoples are an integral part of ASI’s organizational structure. External auditing companies are gradually certifying production sites along the global supply chain to the ASI standard. This way, Audi ensures that compliance with the standard can be effectively monitored. Audi was the first car manufacturer to be awarded the initiative’s ASI Performance Standard and Chain of Custody certificates.

Audi demonstrates its commitment to its values through its involvement in the Global Battery Alliance, founded by the World Economic Forum. Launched in 2017 as a public-private collaboration platform, the GBA aims to ensure social and environmental sustainability in the value chain for the raw materials that go into batteries.

The Global Battery Alliance examines the entire battery value chain, including the challenges related to raw material extraction. It advances sustainable circular recycling concepts and innovations that promote battery sustainability. Audi has been a GBA member since the platform was founded in 2017.

Audi has joined a consortium of German global market leaders and participants from the industrial and scientific worlds to promote uniform standards. The consortium is developing a digital product pass for batteries known as the “EU Battery Pass”. This project is supported by Germany’s Federal Ministry for Economic Affairs and Climate Action.

More diversity in the supply chain

Audi views a diverse supply chain as an opportunity for societal change and long-term success. For that reason, the company has integrated the “Procurement with Purpose” program into its existing sustainability initiatives. Through the program, Audi is making its supply chains more diverse and promoting fair participation. Internally, Audi is making efforts to build knowledge. To this end, the brand with the four rings works with partners who train Audi employees. Externally, Audi collaborates with direct suppliers to develop a common understanding, exchange experiences, and identify problems.

Potential partners for the “Procurement with Purpose” program are identified using two criteria. Firstly, they must create added value at the level of society by offering solutions to societal or ecological challenges (social businesses). Or secondly, they must be led by members of groups underrepresented in the economy (minority-owned businesses), such as women, people with disabilities, or members of the queer community. These companies are then compared to Audi’s corporate needs as part of a matching process to identify potential areas of cooperation.

Together with its partner Yunus Social Business (YSB), Audi piloted the involvement of Audi and its worldwide subsidiaries in social businesses in eight countries in 2023, including Hungary, Italy, Brazil, and Mexico. Numerous workshops, meetings with regional partners, and pitch days with social businesses took place. The first contracts resulting from this endeavor have already been awarded.

Other “Procurement with Purpose” aspects include involvement with and membership of organizations such as the European LGBTIQ Chamber of Commerce and the WEConnect International network.

Climate change mitigation and CO2 reduction: Sustainable from stage one

The transition to electric mobility is shifting a large proportion of carbon emissions to the supply chain. This shift is because the systematic electrification of the model range has kicked a significant proportion of the battery’s carbon footprint up the supply chain. An average of about 20 percent of carbon emissions during the lifecycle of an Audi combustion engine model are attributable to production (using production in Europe as the benchmark) and an estimated 80 percent to the vehicle’s utilization stage. For an Audi BEV (battery electric vehicle), however, an estimated 50 percent of carbon emissions are attributable to production and 50 percent to the utilization stage.

In 2018, Audi launched its CO2 program to improve the carbon balance of the supply chain. The program works with suppliers to identify measures to reduce carbon emissions and optimize potential throughout the manufacturing process of materials and components. Audi uses so-called CO2 hotspots to decarbonize the supply chain efficiently. They allow the company to identify materials or components with the highest potential for reduction. For example, Audi mandates that suppliers of high-voltage battery cells for the new Premium Platform Electric use green power. Suppliers also use low-carbon aluminum for certain components, such as body parts.

All of these measures are integral to AUDI AG's overall sustainability efforts. Their success is measured using the decarbonization index (DCI). The DCI looks at the entire value chain, from extracting raw materials and production to vehicle emissions, recycling, and the provision of fuels and electricity.

Another example of Audi’s efforts to reduce carbon emissions in the supply chain is the Aluminum Closed Loop, launched in 2017. It was rolled out at Ingolstadt, Neckarsulm, and Győr locations and the multi-brand plant in Bratislava. In 2023 alone, the Aluminum Closed Loop process and additional measures such as using low-carbon materials or relying on green power to produce high-voltage battery cells resulted in a net carbon reduction in the supply chain of more than 450,000 tons.

Responsible use of resources from the supply chain up

The Volkswagen Group, and with it Audi, was one of the first major automobile manufacturers worldwide to commit to the Paris Agreement on climate change – and to the goal of achieving net carbon neutrality1 across the company. This has already been achieved at the production level: since 2025, the company has been manufacturing in a carbon-neutral manner at all of its production sites worldwide. Decreasing carbon emissions is an essential step toward reducing the company’s ecological footprint. Guidelines are in place to help partner companies along the supply chain lower their emissions by stipulating the exclusive use of green wind, solar, or hydropower, for example. This requirement promotes using renewable energies in the supply chain and optimizing tendering processes.

Sustainability efforts in Audi’s supply chain go beyond reducing carbon emissions by guaranteeing the sustainable, conserving use of natural resources. Audi takes a hotspot-based approach here, meaning that the company focuses on materials and components with the greatest immediate impact. These include aluminum, steel, plastics, glass, and components for high-voltage batteries. As part of its circular economy strategy, the company’s various projects and measures provide valuable insights into how a circular economy can be implemented. “This approach allows us to minimize the risk of human rights violations and environmental hazards at the same time,” emphasized Patnaik. “Once a raw material has been extracted and processed, the risks associated with those steps are no longer present when the material is recycled.”

However, not all recycled materials are the same. Audi distinguishes between post-industrial recycled materials and post-consumer recycled materials. The latter includes materials that can be recovered from end-of-life vehicles for the duration of a product cycle. The potential is enormous. After all, when a vehicle reaches the end of its service life, it is still far from over. Audi’s explicit goal is to use more recycled materials from post-consumer sources, in particular, to save resources and energy and thus reduce carbon emissions.

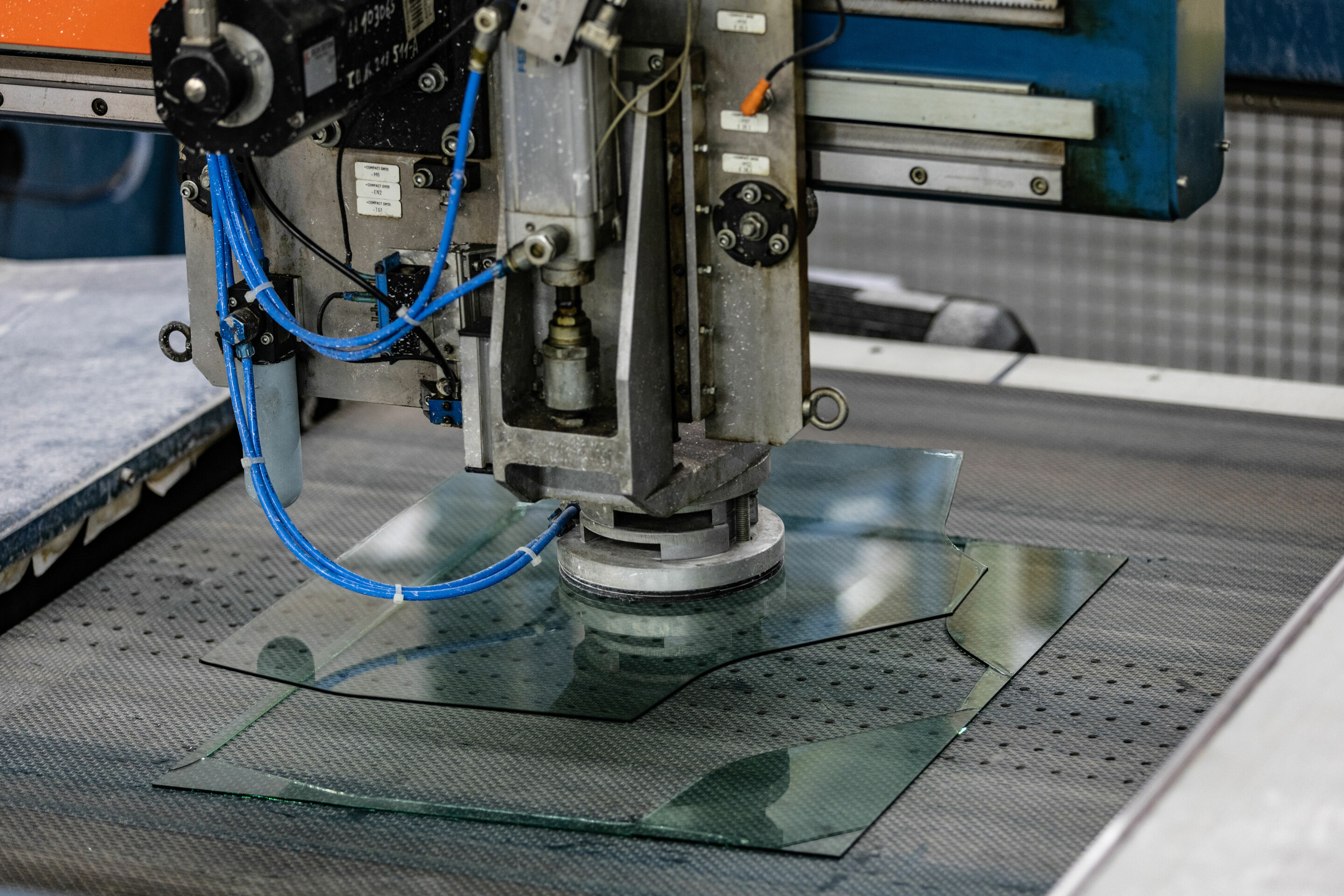

For example, Audi has been using partially recycled windshield glass in series production for the Audi Q4 e-tron since September 2023. For Audi Q6 e-tron series production, part of the steel used to manufacture an outer skin component comes from post-consumer sources, including end-of-life vehicles.

1 Audi understands net-zero carbon emissions to mean a situation in which, after other possible reduction measures have been exhausted, the company offsets the carbon emitted (by Audi’s products or activities) and/or the carbon emissions that currently cannot be avoided in the supply chain, manufacturing, and recycling of Audi vehicles through voluntary offsetting projects carried out worldwide. In this context, carbon emissions generated during a vehicle’s utilization stage, i.e. from the moment it is delivered to the customer, are not taken into account.

As of: March 2025

MediaInfos

-

Circular economy: Audi secures strategic and cost-efficient supply of recycled raw materials

Audi reaches a milestone and continues to drive forward the circular economy in the automotive industry. The company wants to increase the use of secondary materials in vehicles where it is technically feasible and makes ecological and economic sense. The aim is to increasingly use raw materials for new purposes after their initial usage has ended. Audi has therefore been testing approaches to implement this in the MaterialLoop program since 2023. After initially focusing on technical feasibility, the company has now become the first car manufacturer to develop and implement an economically viable recycling concept for recyclates from end-of-life vehicles together with its partner TSR Resource. In this process, steel scrap from vehicles at the end of their life cycle is turned into high-quality post-consumer secondary material and secured for further use in the automotive supply chain.

Circular economy: Audi secures strategic and cost-efficient supply of recycled raw materials

Audi reaches a milestone and continues to drive forward the circular economy in the automotive industry. The company wants to increase the use of secondary materials in vehicles where it is technically feasible and makes ecological and economic sense. The aim is to increasingly use raw materials for new purposes after their initial usage has ended. Audi has therefore been testing approaches to implement this in the MaterialLoop program since 2023. After initially focusing on technical feasibility, the company has now become the first car manufacturer to develop and implement an economically viable recycling concept for recyclates from end-of-life vehicles together with its partner TSR Resource. In this process, steel scrap from vehicles at the end of their life cycle is turned into high-quality post-consumer secondary material and secured for further use in the automotive supply chain.