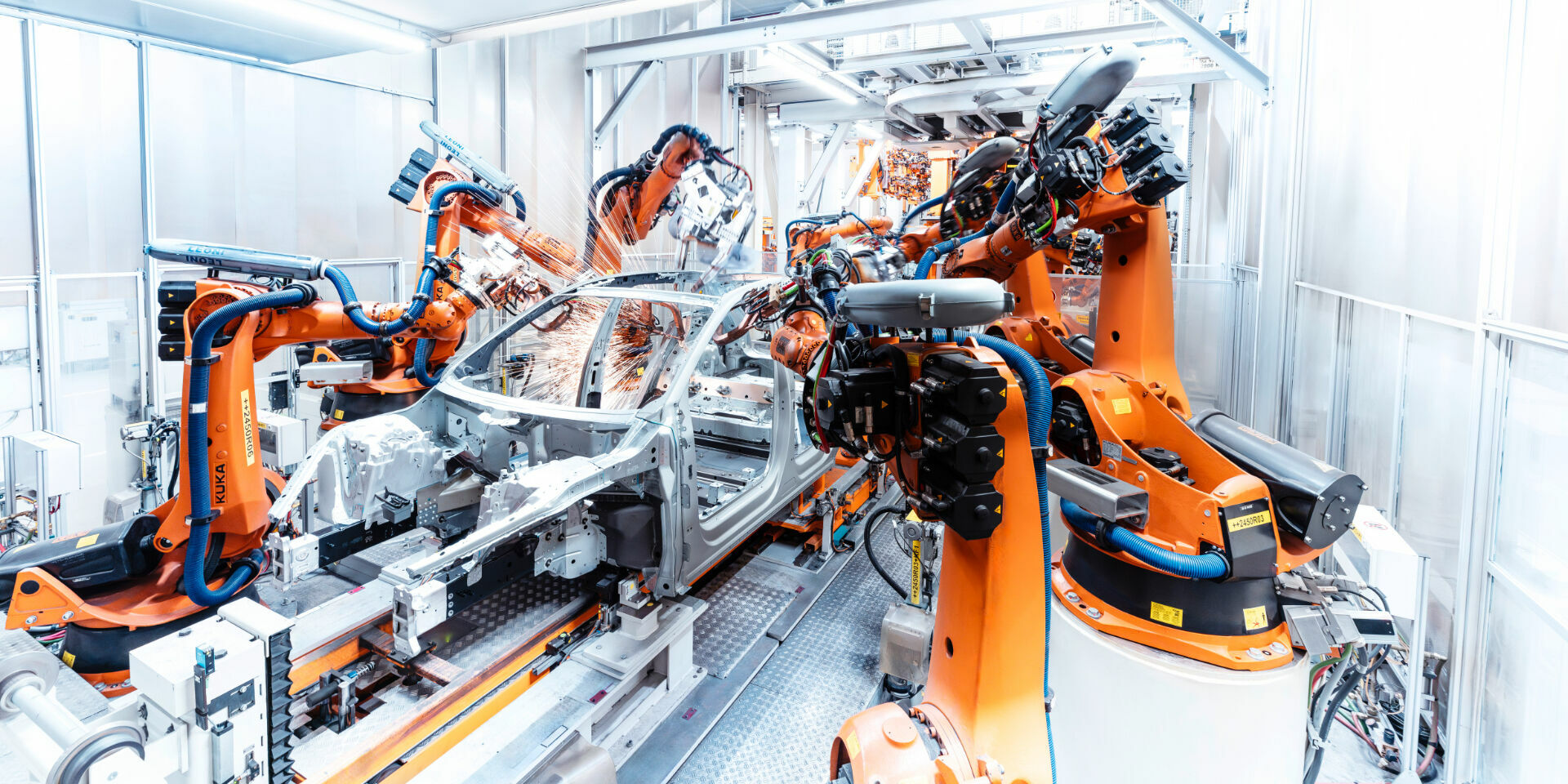

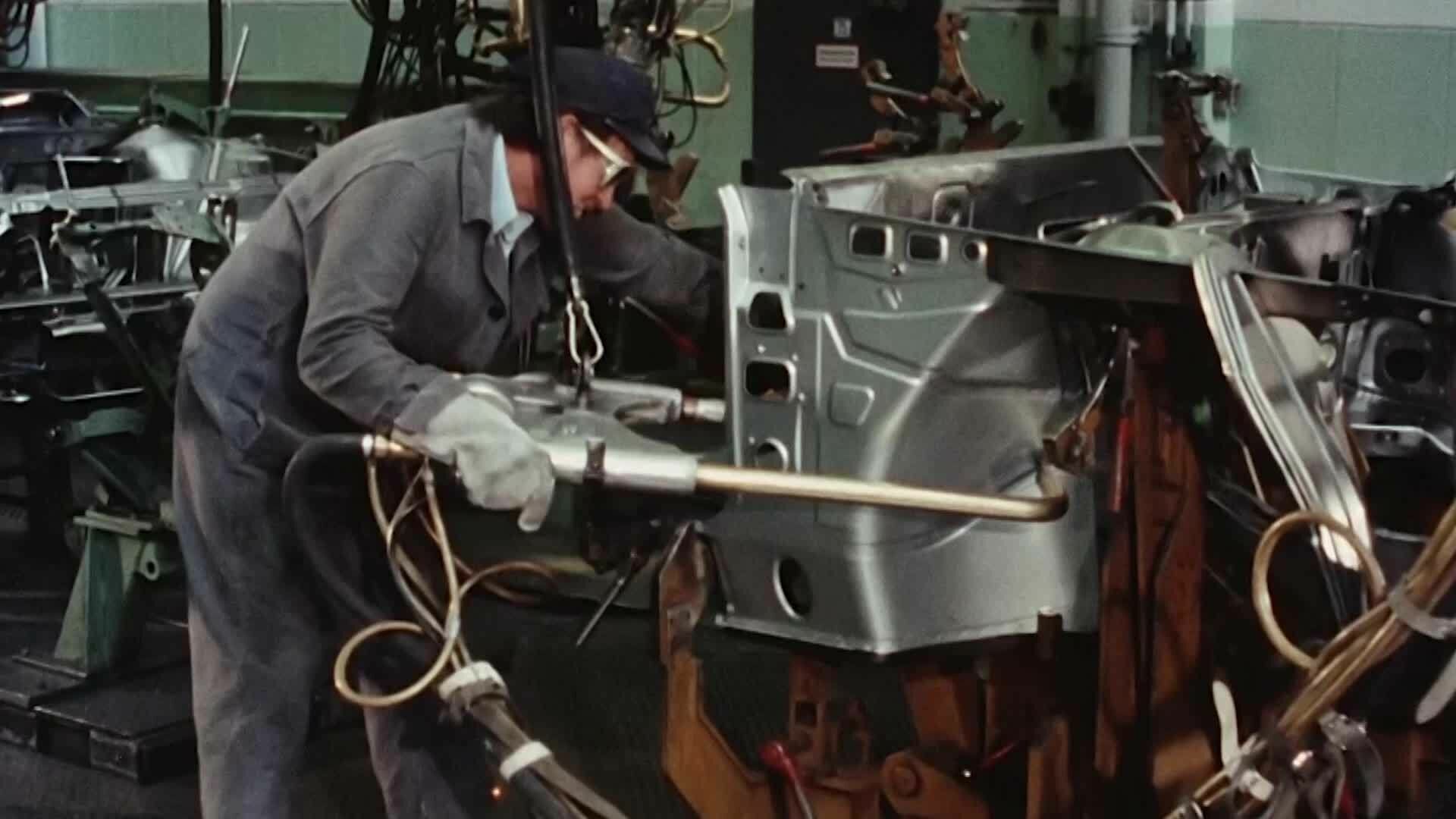

Audi drives digital, sustainable production

Audi is driving the transition to fully connected, highly efficient and sustainable production through digital innovation. New technologies such as virtual planning and the Edge Cloud 4 Production are enabling a paradigm shift in factory automation. Audi approaches production holistically – from employees to automated cycles – and laying the foundation for future-proof, flexible, and resilient value creation.

-

Audi scales up deployment of artificial intelligence in production

Audi is consistently rolling out artificial intelligence (AI) in production and logistics: the company is scaling up its own cloud platform for production and introducing new AI use cases and technologies for large-scale series production. In doing so, the premium manufacturer is relying on the expertise of strong partners. Decades of manufacturing expertise meet smart digital solutions.

Audi scales up deployment of artificial intelligence in production

Audi is consistently rolling out artificial intelligence (AI) in production and logistics: the company is scaling up its own cloud platform for production and introducing new AI use cases and technologies for large-scale series production. In doing so, the premium manufacturer is relying on the expertise of strong partners. Decades of manufacturing expertise meet smart digital solutions. -

Audi develops the picking process of the future

As a real-world laboratory, low-volume production at Böllinger Höfe plays a key role in advancing digitalization in production and logistics in line with Audi's 360factory. Audi Sport is collaborating with partners from the Fraunhofer Heilbronn Research and Innovation Centers HNFIZ to explore the future of the picking process in automotive manufacturing using a new approach. First, a needs analysis identified the areas and activities with the greatest potential to optimize processes and reduce employees' workload. In the next step, the research partners will now trial a wide range of technologies from the fields of artificial intelligence (AI) and robotics in a designated area in production until the end of the year.

Audi develops the picking process of the future

As a real-world laboratory, low-volume production at Böllinger Höfe plays a key role in advancing digitalization in production and logistics in line with Audi's 360factory. Audi Sport is collaborating with partners from the Fraunhofer Heilbronn Research and Innovation Centers HNFIZ to explore the future of the picking process in automotive manufacturing using a new approach. First, a needs analysis identified the areas and activities with the greatest potential to optimize processes and reduce employees' workload. In the next step, the research partners will now trial a wide range of technologies from the fields of artificial intelligence (AI) and robotics in a designated area in production until the end of the year.