Search

All search results for "power electronics"

(537)

Audi Q6 e-tron

The Audi Q6 e-tron marks the start of a new generation of electrically powered vehicles at Audi. With a new platform, electronics architecture, charging and battery technology, as well as a pioneering design for Audi, the Q6 e-tron paves the way to Audi's all-electric future.

Audi SQ6 SUV e-tron

The Audi SQ6 SUV e-tron, the sporty counterpart to the Q6 SUV e-tron, is characterized by specific features in the exterior and interior as well as the chassis. The brake calipers painted in black and the bumpers with aluminum inserts are unmistakable. The optionally available electronically controlled sport air suspension underscores the sporty genes of the SQ6 e-tron.

Images

Videos

Drive type All-wheel drive

Number of electric motors front axle / rear axle 1 / 1

Electrical torque output front / rear in Nm (lb-ft) 275 / 580 (202.8 / 427.8)

Battery type / Gross / net battery capacity in kWh Lithium-Ion / 100 / 94.9

Top speed in km/h (mph) 230 (142.9) (governed)

electrical acceleration, 0-100 km/h (62.1 mph) in s 4,4

Electrical range, combined in km (mi) 560 - 597 (348.0 - 371.0)

Electric power consumption, combined in kWh/100 km (62.1 mi) 18.6 - 17.5

CO2 emissions, combined in g/km (g/mi) 0

CO2 class A

Unladen weight without driver / with driver / gross weight limit in kg (lb) 2350 / 2425 / 2965 (5180.9 / 5346.2 / 6536.7)

With a new platform, electronic architecture, charging and battery technology, and a powerful SUV design that breaks new ground, the Q6 SUV e-tron paves the way to the fully electric future at Audi.

Back then, the twin-turbo V6 had a power output of 279 kW (380 PS). The new RS 4 Avantnow puts out 331 kW (450 PS), which equals an output of 155.5 PS per liter. This means that the RS 4 Avantonly needs between 3.9 and 4.1 seconds (depending on equipment) to go from zero to 100 km/h (62 mph). The TFSI engine weighs just 182 kg (401.2 lbs.), which is 31 kilograms (68.3 lbs.) less than the V8 engine in the 2012 predecessor model. This improves the gross weight and the axle load distribution—two prerequisites for impressive performance. The twin-turbo V6 applies an impressive 600 Nm of torque to the crankshaft in a broad engine speed range from 1,900 to 5,000 rpm. The RS dynamic package increases the electronically governed top speed from 250 to 280 km/h (155 to 174 mph), in conjunction with the optional competition packages to 290 km/h (180 mph). The two turbochargers of the 2.9 TFSI are each assigned to a cylinder bank and build up a boost pressure of up to 1.5 bar. Like with all V6 and V8 engines from Audi, the turbochargers are installed within the 90-degree interior “V” of the cylinder banks, and thus the exhaust side of the cylinder heads is on the inside, while the intake side is on the outside of the engine. This layout enables compact construction and short gas flow paths with minimal flow losses, allowing the 2.9 TFSI to respond especially quickly to movement of the accelerator pedal.

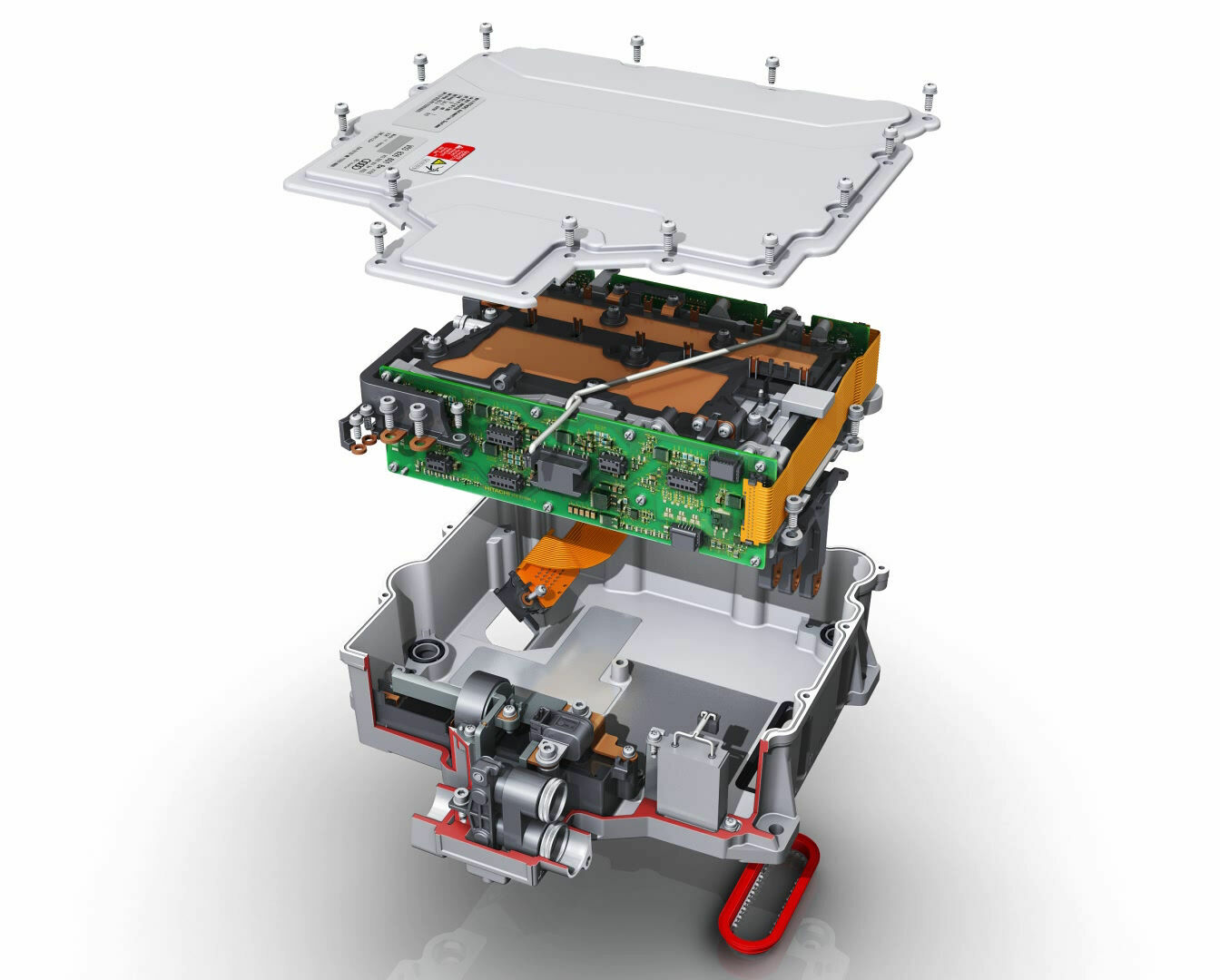

When developing the new electric motors, the focus was on a modular electric axle system with optimal acoustics, efficiency, and power density. Another goal of the development in this area was a scalable electric drive system with a high level of component integration. The completely newly developed modular drive system consists of three main components: electric motor, power electronics (pulse inverter), and transmission. All components are characterized by a higher degree of efficiency. They are more compact than the current electric models in the portfolio and have a scalable design. This means that the torque output can be varied by changing the length of the electric motor. The newly developed electric motors also require around 30 percent less installation space than those previously used in Audi's electrically powered models. The new design has also made it possible to reduce the weight by around 20 percent. The particularly compact and efficient electric motors are built in Győr, Hungary. The largest powertrain plant in the world not only manufactures the electric motors but also a large proportion of the gearboxes. A key advantage of the newly developed electric motors is their efficiency. This is primarily thanks to a new hairpin winding in the stator, silicon carbide semiconductors in the pulse inverter, as well as dry sump lubrication and an electric oil pump in the transmission. The new hairpin winding, which is being used in the Q6 e-tron for the first time at Audi, maximizes the current flow in the stator of the electric motor. This method also enables a higher number of windings: The fill factor is now 60 percent instead of the 45 percent reached with the conventional windings used previously.

In search of driving pleasure: quattro drive and suspension of the Audi e-tron

In search of driving pleasure: quattro drive and suspension of the Audi e-tron

If the driver demands more power than the rear electric motor can supply, the electric all-wheel drive redistributes torque as required to the front axle. This also happens predictively even before slip occurs in icy conditions or when cornering fast, or if the car understeers or oversteers. It takes just 30 milliseconds or so from the system detecting the driving situation and the torque from the electric motors kicking in – much faster than with conventional quattro technology. The reason is that with the electric all-wheel drive a mechanical clutch is not engaged but electricity is simply distributed. And that is almost instantaneous with absolute precision. So even with sudden changes in the coefficients of friction and extreme driving situations the full quattro performance is guaranteed. Intelligent connectivity: cooperation between control units Thanks to the many years of experience and quattro expertise Audi has developed all the main software components and their connectivity in-house. Numerous control units work together closely in the Audi e-tron and coordinate all functions for the powertrain. First and foremost is the drive control unit. It controls the distribution of the drive torque between the two electric motors, with the emphasis always on the optimum performance and, in turn, high efficiency. In addition to the state of charge and the temperature of the high-voltage battery and electric motors, the drive control unit also takes into account the selected drive range and the power requirement. For instance in drive range S with activation of the kickdown, the boost power of 300 kW is released to deliver maximum performance. In accordance with the required torque of the drive control unit, the power electronics incorporated in the electric drive supply the electric motors with power.

Rainer Schirmer - Biography

Rainer Schirmer - Biography

In 1982, he began his vocational training as a power plant electronics technician at AUDI AG in Neckarsulm. After completing his apprenticeship, he worked as a maintenance technician in various departments. In 2015, he became an IHK-certified business administrator. In 2000, Schirmer was elected a workers’ representative and joined the committee of workers’ representatives in 2001. He was elected to the Works Council in 2002 and joined the Works Committee at the Neckarsulm plant in 2009. In 2016, he was elected Vice Chairman of the Works Council, which also made him a member of the General Works Council of AUDI AG. That same year, he became a member of the Group Works Council of Volkswagen AG. In 2021, Schirmer was appointed Chairman of the Works Council of AUDI AG at the Neckarsulm plant and was also elected Vice-Chairman of the General Works Council of AUDI AG. He has also been a member of the Economic Committee of AUDI AG and the administrative board of Audi BKK since 2016. In 2018, he was appointed to the Supervisory Board of AUDI AG and joined its Presiding Committee in 2022. Also in 2022, Schirmer was elected an honorary member of the executive board of IG Metall. In addition to his professional responsibilities, Schirmer is actively involved in social initiatives through the Works Council and serves on the Board of Trustees of the Volkswagen Workforce Foundation.

Sophisticated yet lightweight suspension and steering systems, powerful brakes and highly intelligent electronics together make for a fascinating driving experience.

Images

Videos