Search

All search results for "Audi TT RS Coupe"

(117)

Audi TT RS Coupé (until 2023)

With its clean lines, this sports car has been an inspiration the world over since its premiere in 1998 due to its driving pleasure and puristic design language. The RS version impresses with its special five-cylinder turbo performance, a one-of-a-kind sound that gets under your skin, and highly dynamic quattro all-wheel drive.

Pictures Audi TT RS Coupé iconic edition (until 2023)

Videos Audi TT RS Coupé iconic edition (until 2023)

Bilder Audi TT RS Coupé (until 2023)

Videos Audi TT RS Coupé (until 2023)

Engine type R 5 engine

Displacement in cc / bore x stroke in mm / compression 2480 / 82.5 x 92.8 / 10.0

Max. power output in kW (hp) / at rpm 294 (400) / 5850 - 7000

Max. torque in Nm (lb-ft) / at rpm 480 (354.0) / 2250 - 5850

Top speed in km/h (mph) 250 (155.3) (governed)

Acceleration, 0-100 km/h (0-62.1 mph) in sec 3.7

Fuel consumption, combined according to WLTP in l/100 km (US mpg) 9.2 - 8.8 (25.6 - 26.7)

CO2 emissions, combined according to WLTP in g/km (g/mi) 208 - 201 (334.7 - 323.5)

Unladen weight without driver / with driver / gross weight limit in kg (lb) 1475 (3251.8) / 1550 (3417.2) / 1875 (4133.7)

400 hp power output, from 0 to 100 km/h (62.1 mph) in 3.7 seconds, top speed of up to 280 km/h (174.0 mph): With the new aluminum five-cylinder engine, the TT RS Coupé* and TT RS Roadster* deliver outstanding performance. Available for the first time in a series-production Audi: Matrix OLED rear lights. Like the Audi virtual cockpit and the comprehensive infotainment range, they once again stand for “Vorsprung durch Technik.”

*The fuel consumption and emissions values of all models available on the German market and named in this text are listed in the last chapter of this basic information document

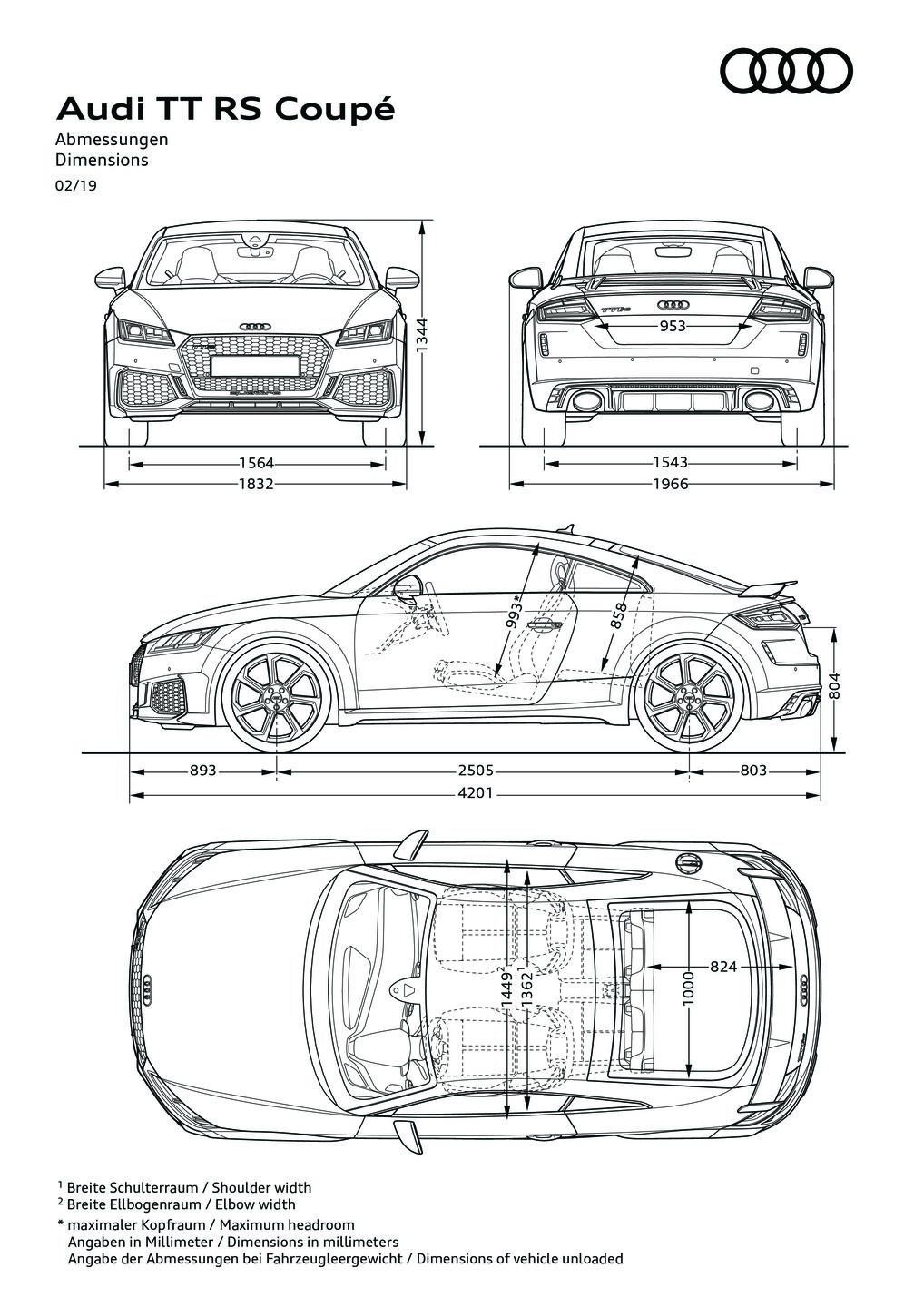

Dimensions TT RS Coupé

Dimensions TT RS Coupé

2505 1543 4201 1966 1564 1832 893 803 824 1 3 4 4 99 3* 953 8 0 4 1 3 6 2 1 1 4 4 9 2 85 8 1 0 0 0 Audi TT RS Coupé Abmessungen Dimensions 02/19 * maximaler Kopfraum / Maximum headroom Angaben in Millimeter / Dimensions in millimeters Angabe der Abmessungen bei Fahrzeugleergewicht / Dimensions of vehicle unloaded 1 Breite Schulterraum / Shoulder width 2 Breite Ellbogenraum / Elbow width

Audi is sending the most powerful TT ever into the competitive field. Its newly developed five-cylinder engine delivers 400 hp – accompanied by an unmistakable sound. Driving pleasure guaranteed! Muscular front end, large air inlets, low-positioned spoiler, fixed rear wing – at first glance, the Audi TT RS* clearly hints at just how much power there is under its streamlined skin. Its new five-cylinder aluminum engine delivers 400 hp, which is 60 more than the power of the previous model. A full 480 Nm (354.0 lb-ft) of torque is applied to the front and rear wheels, and a traction control system manages its distribution for maximum acceleration with minimal slip. As a result, the Coupé takes 3.7 seconds to sprint from 0 to 100 km/h (62.1 mph), and the Roadster takes 3.9 seconds. No other TT has sprinted this fast. The brilliant torque is accompanied by typical five-cylinder sound – which is music to the ears of horsepower purists. This sound passes through the RS exhaust system and is projected to the surroundings via two large oval tailpipes. Other eye-catching features at the rear are the new Matrix OLED lights in 3D design, which are being implemented for the first time in a production Audi. This much power requires a stiff chassis setup. At a height of just 1.34 meters (4.4 ft), the Audi TT RS is low to the asphalt, and it is both light-footed and under control as it conquers curves. The direct steering ratio gives the driver the feeling of being one with the road. No matter how intensively the driver turns the grippy sport steering wheel, the low-mounted sport seat with the strong contours of its side bolsters holds the driver in position. In the Roadster, a switch initiates open-air driving fun. It opens the car’s soft top – even while driving at speeds up to around 50 km/h (31.1 mph). Inside, the TT RS has an extremely sporty appearance – with aluminum or carbon trim elements and RS logos.

A timeless design icon: The Audi TT turns 25

A timeless design icon: The Audi TT turns 25

Inspired by Bauhaus: Coupé study from 1995 began series production in 1998 178,765 first-generation Audi TT Coupés had rolled off the production line by 2006 Audi designer Torsten Wenzel introduced the study to series production: “The Audi TT is a driving sculpture”

Twenty-five years, three generations: The brand with the four rings wrote design history with the Audi TT. Since its debut in 1998, the sports car has struck a chord with people worldwide thanks to the fun it promises drivers and its clear design language. „Auto Europe“ voted it the best new car of the year in 1999.

In the mid-1990s, the Audi A8 luxury model elevated the Audi brand to a higher position and gradually led to the renaming of the model series: The Audi 80 became the Audi A4, and the Audi 100 was dubbed the Audi A6. Introduced in 1994, the Audi A4 was the first model to embody Audi’s new design language. Next was the Audi A3 premium compact car, launched in 1996, and the second generation of the Audi A6, introduced in 1997. In the course of emotionalizing the brand through a fresh, progressive design, American designer Freeman Thomas, under the then Head of Design Peter Schreyer, created a puristic sports car in the Audi TT Coupé. Audi presented the study to an enthusiastic trade show audience at the IAA in Frankfurt in September 1995. The model name “TT” is reminiscent of the legendary Tourist Trophy on the Isle of Man, one of the oldest motorsports events in the world and one where NSU and DKW celebrated great successes with their motorcycles. The name “TT” also recalls the sporty NSU TT of the 1960s. The Audi TT Coupé’s deliberate departure from the usual Audi nomenclature underscored the complete novelty of the model. Designer Wenzel: “In the Audi TT, every shape has a clear function” In December 1995, the decision was made to mass-produce the Audi TT Coupé.

Successful for decades: 662,762 units across three generations built over 25 years Design inspired by Bauhaus: every shape has a clear function Vorsprung durch Technik: New technologies launched with the TT, including Audi magnetic ride, Audi virtual cockpit, and OLED technology

A quarter of a century of TT history: When Audi presented the concept car at the IAA in 1995, public opinion became clear right away: “This car should be mass-produced – exactly as it is!” With the series debut in 1998, the Audi TT wrote design history and was built across three generations as a Coupé and Roadster.

With a vision of “a car for enthusiasts,” Audi presented the Audi TT Coupé as a sports car concept at the IAA in Frankfurt in the fall of 1995. Shortly afterward, the decision was made to mass-produce it. Torsten Wenzel, the exterior designer at Audi who helped introduce the study to series production, recalls: “To us, the greatest praise was when the trade press noted appreciatively that not much had changed from the concept to production model, although we did, of course, have to adapt many details due to the technical specifications for the production version, including the proportions.” Most noticeable was the integration of a rear side window, which elongated the car’s profile and increased the sports car’s dynamics. For Wenzel, the TT remains “a driving sculpture, with highest-quality surfaces and lines.” The body of the Audi TT appears to be made from one piece, Wenzel says, and the front end without traditional bumper overhangs emphasizes its distinctive shape. Another design element contributes to the unmistakable silhouette of the Audi TT Coupé: the circle – “the perfect graphic shape,” as Wenzel describes it. Numerous circular elements inspired the sports car’s exterior and interior design. Inspired by Bauhaus, every line in the Audi TT has a purpose, every shape a function. “At Audi Design, we always follow the philosophy of ‘less is more.’

TT RS Coupé (until 2023) (294 kW)

TT RS Coupé (until 2023) (294 kW)

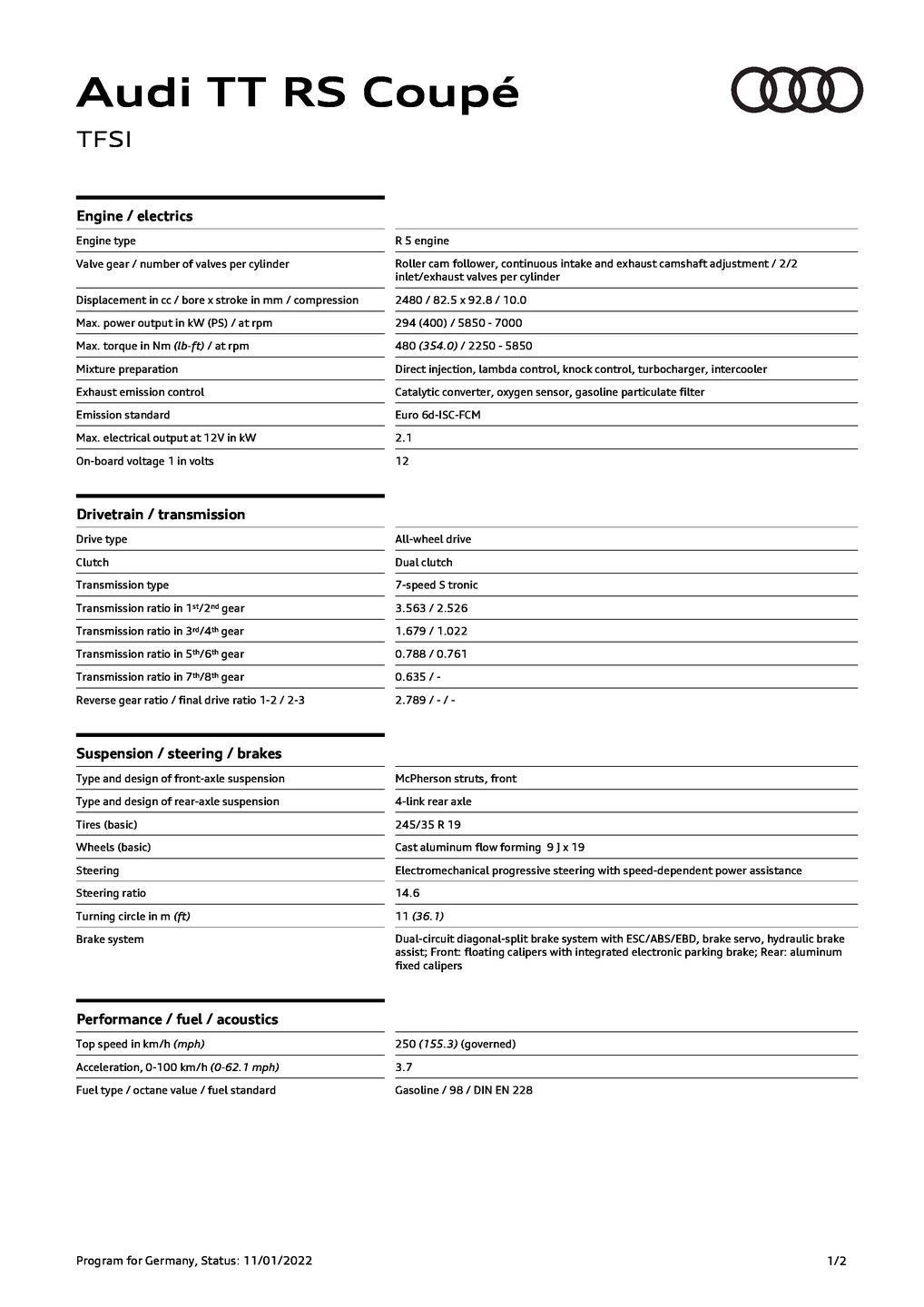

Program for Germany, Status: 11/01/2022 1/2 Audi TT RS Coupé TFSI Engine / electrics Engine type R 5 engine Valve gear / number of valves per cylinder Roller cam follower, continuous intake and exhaust camshaft adjustment / 2/2 inlet/exhaust valves per cylinder Displacement in cc / bore x stroke in mm / compression 2480 / 82.5 x 92.8 / 10.0 Max. power output in kW (PS) / at rpm 294 (400) / 5850 - 7000 Max. torque in Nm (lb-ft) / at rpm 480 (354.0) / 2250 - 5850 Mixture preparation Direct injection, lambda control, knock control, turbocharger, intercooler Exhaust emission control Catalytic converter, oxygen sensor, gasoline particulate filter Emission standard Euro 6d-ISC-FCM Max. electrical output at 12V in kW 2.1 On-board voltage 1 in volts 12 Drivetrain / transmission Drive type All-wheel drive Clutch Dual clutch Transmission type 7-speed S tronic Transmission ratio in 1st/2nd gear 3.563 / 2.526 Transmission ratio in 3rd/4th gear 1.679 / 1.022 Transmission ratio in 5th/6th gear 0.788 / 0.761 Transmission ratio in 7th/8th gear 0.635 / - Reverse gear ratio / final drive ratio 1-2 / 2-3 2.789 / - / - Suspension / steering / brakes Type and design of front-axle suspension McPherson struts, front Type and design of rear-axle suspension 4-link rear axle Tires (basic) 245/35 R 19 Wheels (basic) Cast aluminum flow forming 9 J x 19 Steering Electromechanical progressive steering with speed-dependent power assistance Steering ratio 14.6 Turning circle in m (ft) 11 (36.1) Brake system Dual-circuit diagonal-split brake system with ESC/ABS/EBD, brake servo, hydraulic brake assist; Front: floating calipers with integrated electronic parking brake; Rear: aluminum fixed calipers Performance / fuel / acoustics Top speed in km/h (mph) 250 (155.3) (governed) Acceleration, 0-100 km/h (0-62.1 mph) 3.7 Fuel type / octane value / fuel standard Gasoline / 98 / DIN EN 228 Program for Germany, Status: 11/01/2022 2/2 Consumption / emission* Fuel consumption, combined according to WLTP in l/100

The new TT RS* is a powerhouse – in the closed and the open version. “The heart of the second-generation TT RS is an all-new five-cylinder engine made of aluminum,” said Stephan Winkelmann, CEO of quattro GmbH. “With 400 hp, it puts out 60 hp more than the previous model. The new Matrix OLED rear lights also underscore the compact sports car’s position as a technology leader.” Impressive performance: the new five-cylinder engine A jury of international motor journalists has voted the 2.5 TFSI “Engine of the Year” seven times in a row. Now Audi has further developed the five-cylinder engine in all areas – with lightweight construction measures, reduced internal friction and increased power delivery. As a result, the turbo engine gains a good 17 percent increase in performance at an unchanged capacity of 2,480 cc. At 294 kW (400 hp), it is more powerful than ever before. The engine’s maximum torque of 480 Nm (354.0 lb-ft) is available between 1,700 and 5,850 rpm. It ensures fantastic pulling power, accompanied by an unmistakable sound. Because of the 1-2-4-5-3 ignition sequence, ignition alternates between adjacent cylinders and those far apart from one another. This brings with it a very special rhythm. The TT RS Coupé accelerates from 0 to 100 km/h (62.1 mph) in 3.7 seconds, the Roadster in 3.9 seconds – this corresponds to the level of a supercar. Audi can govern the top speed to 250 km/h (155.3 mph) or an optional 280 km/h (174.0 mph). Despite increased performance, the fuel consumption of the TT RS Coupé is just 8.2 liters per 100 kilometers (28.7 US mpg); the TT RS Roadster uses 8.3 liters (28.3 US mpg) on average. For the best traction and plenty of driving pleasure: the quattro drive The power of the 2.5 TFSI engine flows via a seven-speed S tronic, which shifts at lightning speed, to the quattro permanent all-wheel drive. Its multi-plate clutch distributes power fully variably between the two axles. This ensures strong grip and plenty of driving pleasure.