Audi in Brussels

Audi in Brussels (Belgium)

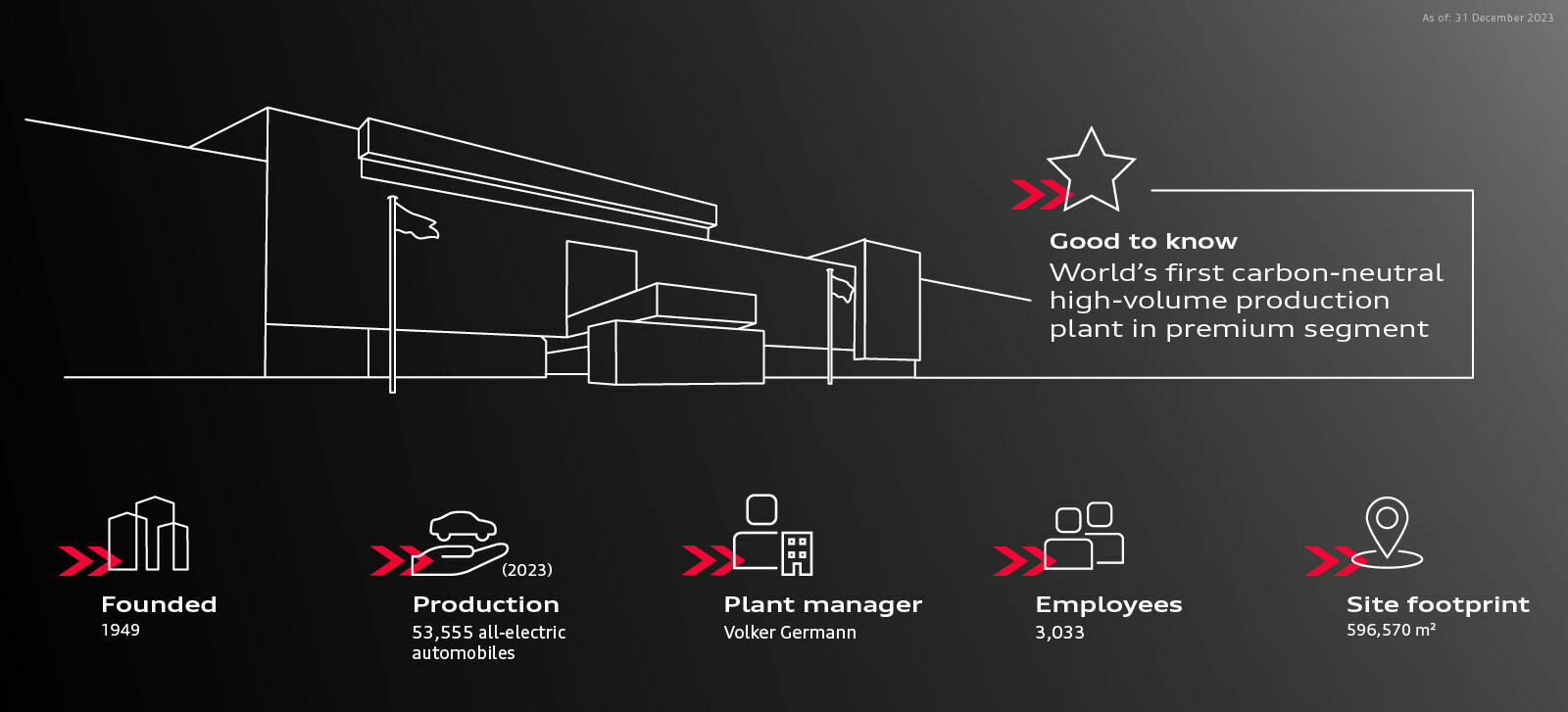

Since the December 2022, Audi Brussels has been manufacturing the Audi Q8 e-tron and the Audi Q8 Sportback e-tron. Previously, Audi’s first all-electric model, the Audi e-tron was made here. At the start of 2020, it began series production of the Audi e-tron Sportback. Furthermore, the Brussels plant is the world’s first carbon-neutral high-volume production facility in the premium segment, as certified by independent experts.

Current model series at location: Audi Q8 e-tron, Audi Q8 Sportback e-tron