Drive system

Back to overviewNot all automatic transmissions are the same, and not all quattro drive systems are the same. In this section, we decipher the different technologies, explain their modes of operation as well as concepts like the Audi valvelift system and ‘rightsizing’.

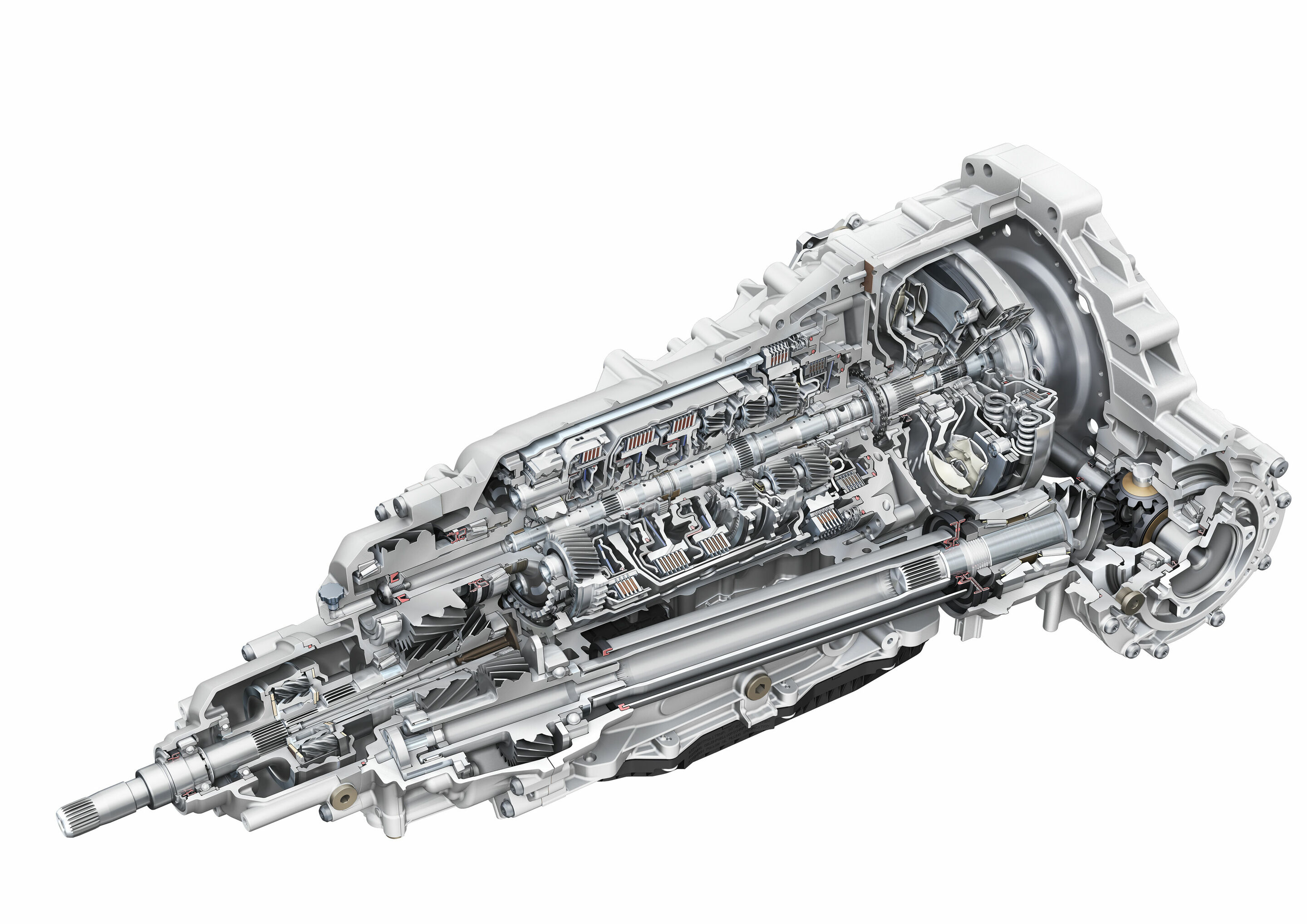

Eight-speed tiptronic

The eight-speed tiptronic is a classic torque-converter automatic transmission whose great strength lies in its high level of shifting and drive off comfort. Gear shifts are gentle, spontaneous, fast and highly flexible. Audi uses it in many models with a longitudinally mounted engine. Thanks to its eight speeds, jumps in rpm are small between gears, and the engine always runs near its ideal operating point. An rpm-adaptive torsion damper balances out undesired engine vibrations and enables efficient driving at extra-low engine speeds.

Also playing a large role in the efficiency ensemble is the torque converter lockup clutch with integrated damper. Under normal driving conditions, the lockup torque converter connects the transmission directly to the engine. It works with limited slip in certain situations, which – in interplay with the integrated damper – permits very low engine speeds without vibrations occurring. If the car is stationary, an internal clutch decouples the transmission from the engine, even if the “D” stage is still selected – this avoids losses due to oil circulation in the converter. As soon as the driver releases the brake, the clutch closes, and the damping effect of the torque converter ensures a smooth drive-off.

The dynamic shift program (DSP), which controls the eight-speed tiptronic, is housed in a small steel box within the gear-shift unit. It utilizes a fast processor. In the “D” mode, DSP autonomously sets the optimal shift point. To enable an efficient mode of driving, it gives preference to large gears and low engine speeds. In a second shift gate, the tiptronic allows manual intervention in the automatic transmission’s operation. This allows downshifting, e.g. on winding descents to boost engine braking or for driving in an exceptionally sporty style. In sport mode, the automatic transmission boosts driving dynamics by setting later shift points. The selector lever communicates fully electronically, without any mechanical connection with the transmission (shift-by-wire).

The eight-speed tiptronic is able to work together with the Audi start-stop system. It integrates a small, permanently filled hydraulic reservoir for this purpose. When restarting after a stop, its oil volume – of around 100 milliliters (0.1 US qt) – is pressurized by a spring-loaded piston, which is necessary for drive-off. The transmission is ready to start within a very short period of time.

In some Audi models the eight-speed tiptronic has an electric oil pump. It handles lubrication of the transmission and enables engagement of the gear that is needed for an engine restart after a coasting phase. Thanks to the mild hybrid technology, this makes it possible for the vehicle to shut off its engine during the drive when it is not needed for propulsion. When the vehicle is coasting and the engine is running in idle, a clutch is open in the area of the wheel sets. The transmission control unit detects stop-and-go situations and ensures very comfortable driving starts.

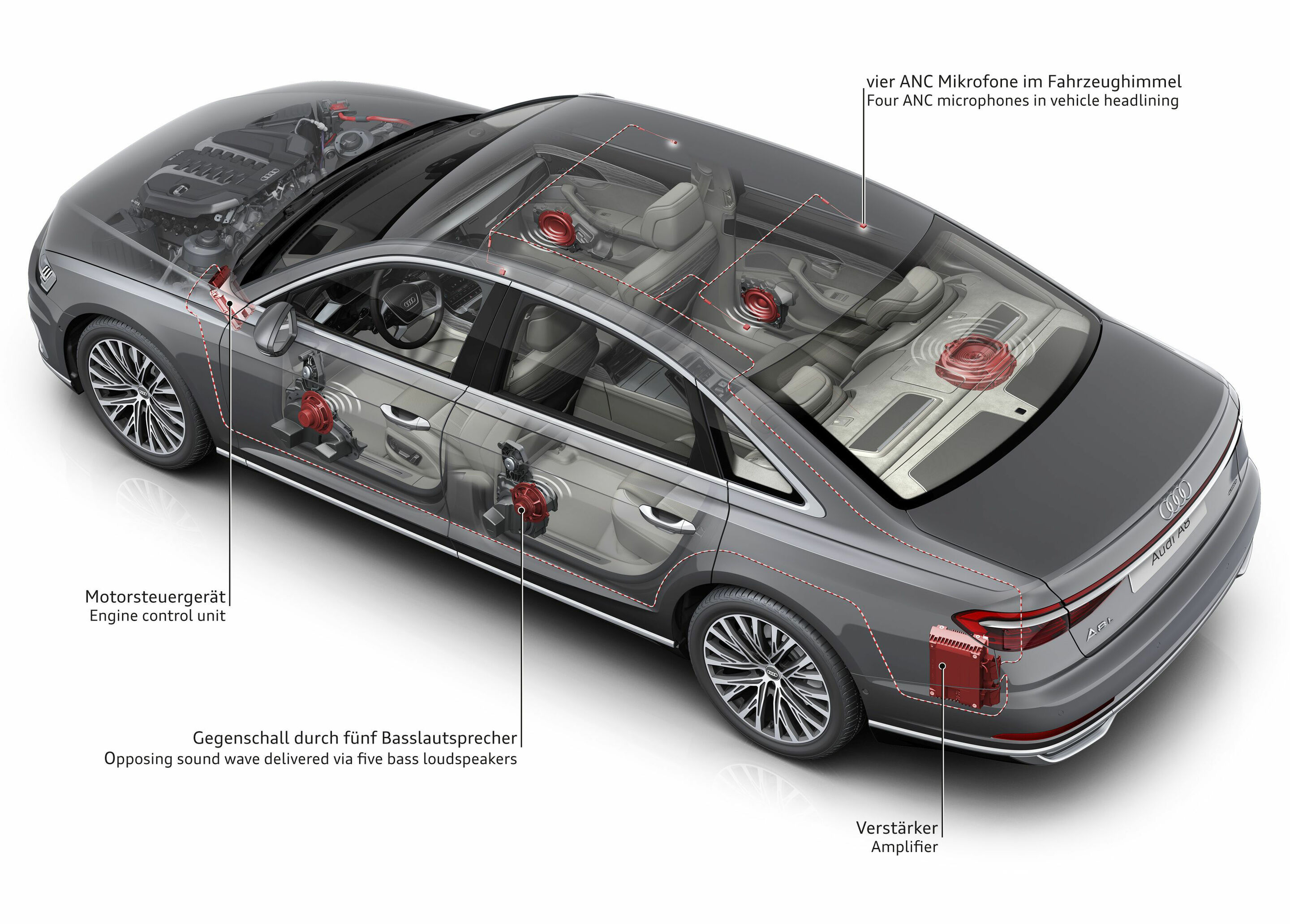

Active noise cancellation

Active Noise Cancellation (ANC) is used to eradicate undesirable noise with cancellation sound. The system applies the principle of destructive interference, which is also known as the cancellation sound principle. When two sound waves of the same frequency are superimposed, their amplitudes cancel one another if they have the same magnitude and exhibit a phase offset of 180 degrees.

In the car interior, small microphones are used to record the background noise in multiple zones. From their signals, the ANC control unit computes a differentiated spatial sound field. It supplements this with information about engine speed. In all zones in which the system detects noise for which it has been pre-calibrated, it initiates a precisely modulated cancellation sound. The ANC system is always active – whether the sound system is turned on, turned off or set to loud, soft or mute. ANC works with all available factory-installed sound systems.

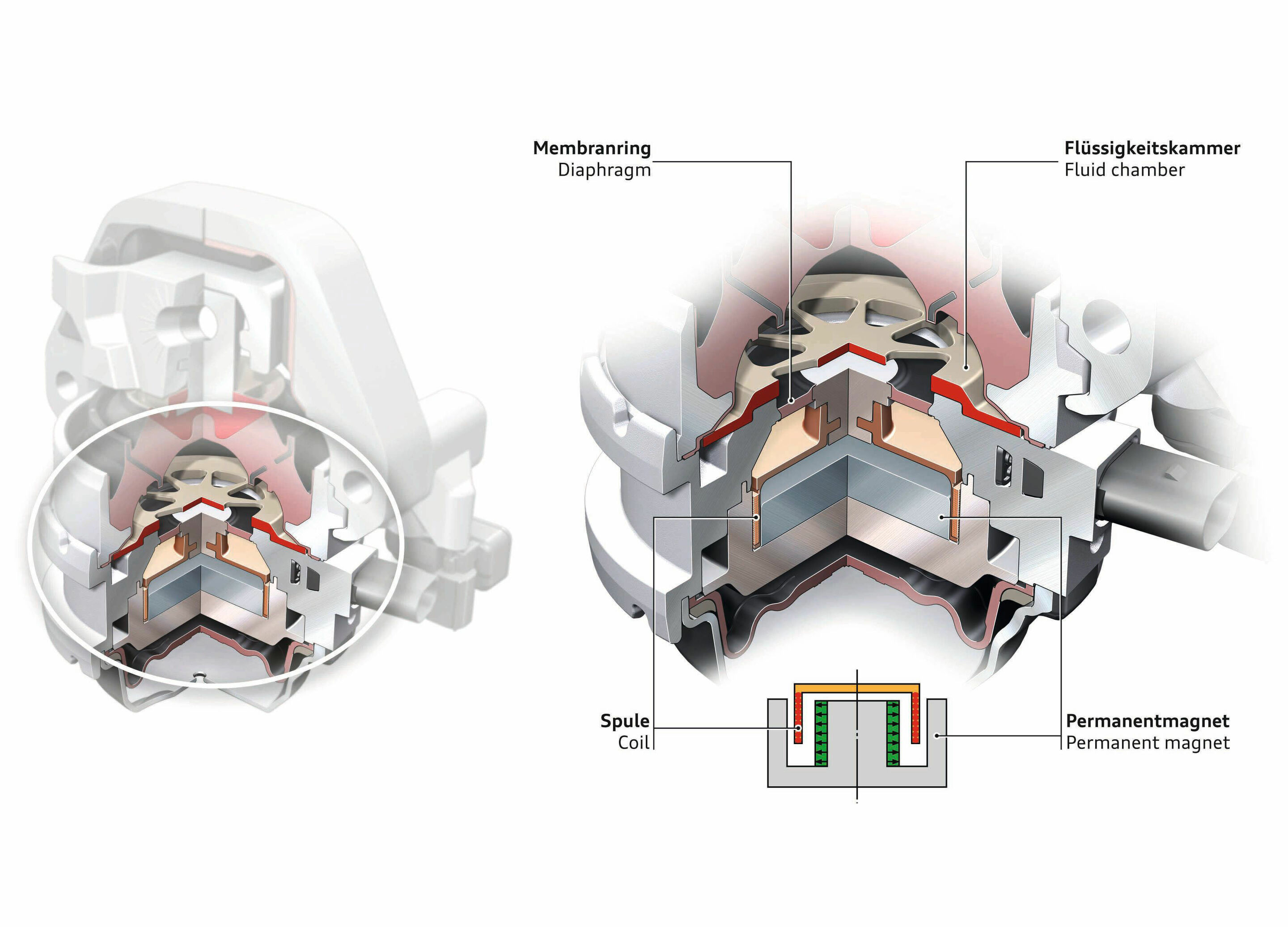

Active engine mounts

Active engine mounts reduce undesirable vibration excitation from the engine by generating compensating counter-oscillations. The hydraulically damped engine mounts utilize an electromagnetic oscillating coil actuator for this purpose. To ensure that it always supplies the proper control signal – even during quick changes in vehicle state – an algorithm constantly evaluates the data of accelerometers mounted in the engine compartment and adapts the control signal to accordingly.

Active engine mounts help to enhance ride comfort in models with cylinder deactivation and in diesel models. They are also used in plug-in hybrid vehicles to ensure a uniform driving experience while switching between operating modes.

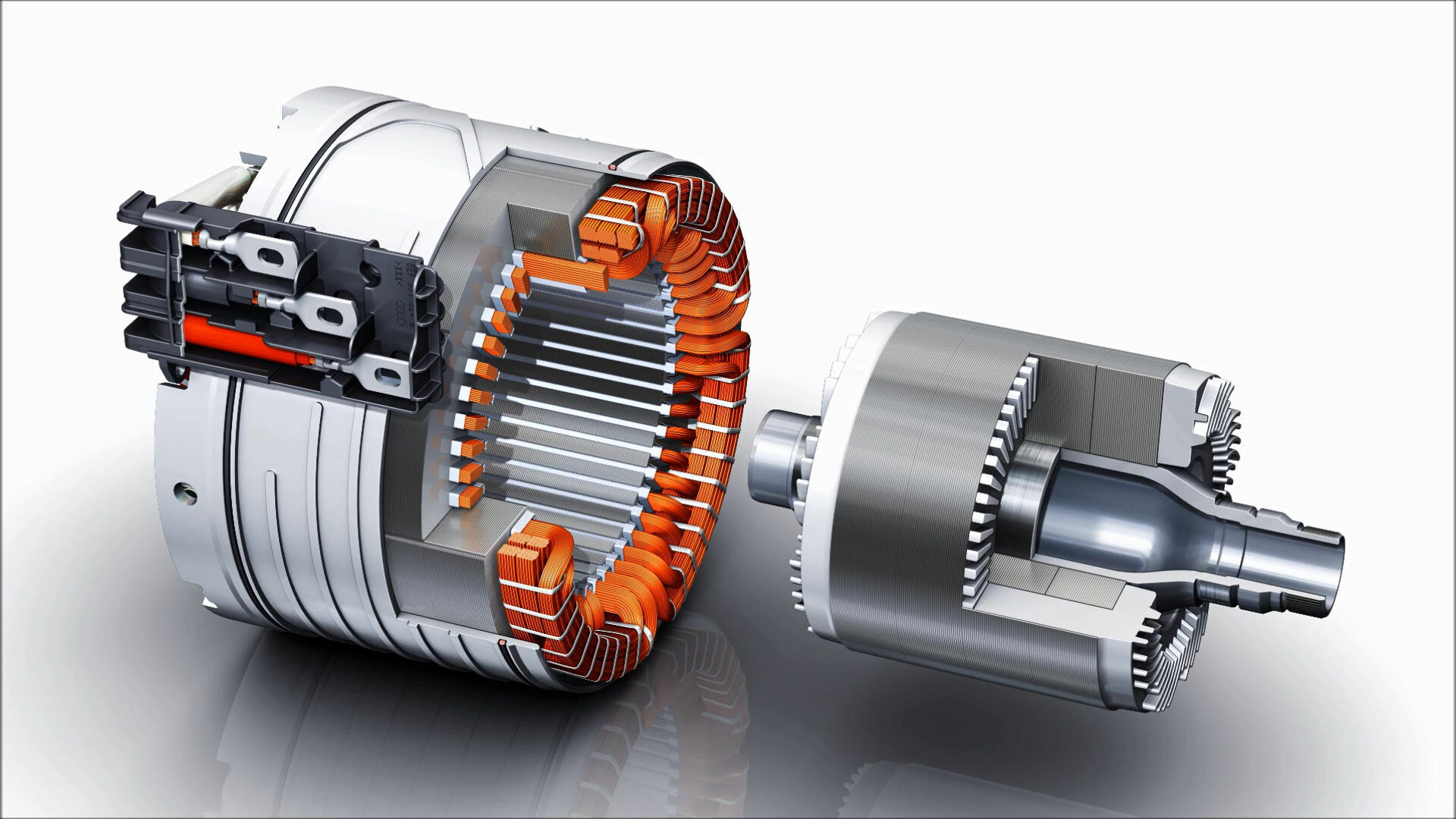

Asynchronous motor

A three-phase asynchronous motor comprises two major parts: the outer, fixed stator and the rotor contained therein. The stator is a sheet package consisting of thin, magnetically conductive electrical sheets. Inside these are copper wire coils to which the three three-phase current phases from the power electronics are connected. When a voltage is applied to them, a circumferential (rotating) magnetic field is produced. The stator’s rotating field induces a further magnetic field in the rotor – the rotor is carried along with the excitatory rotating magnetic field of the stator with a low rotational speed difference, i.e. asynchronously. If the rotor turns more slowly than the rotating magnetic field, the electric motor in the car works as a traction motor. In the opposite case, it becomes a generator and converts kinetic energy into electrical energy. The asynchronous motors do not produce any electrically induced drag losses in deenergized condition, which makes them highly efficient. Besides they can increase their output for a short period of time and thus maximize the performance of the car in the boost mode. Not only are they very light due to the aluminum rotor, they also have further advantages: They require little maintenance and are particularly robust. Furthermore, no rare earth elements are used in the production of the electric motors.

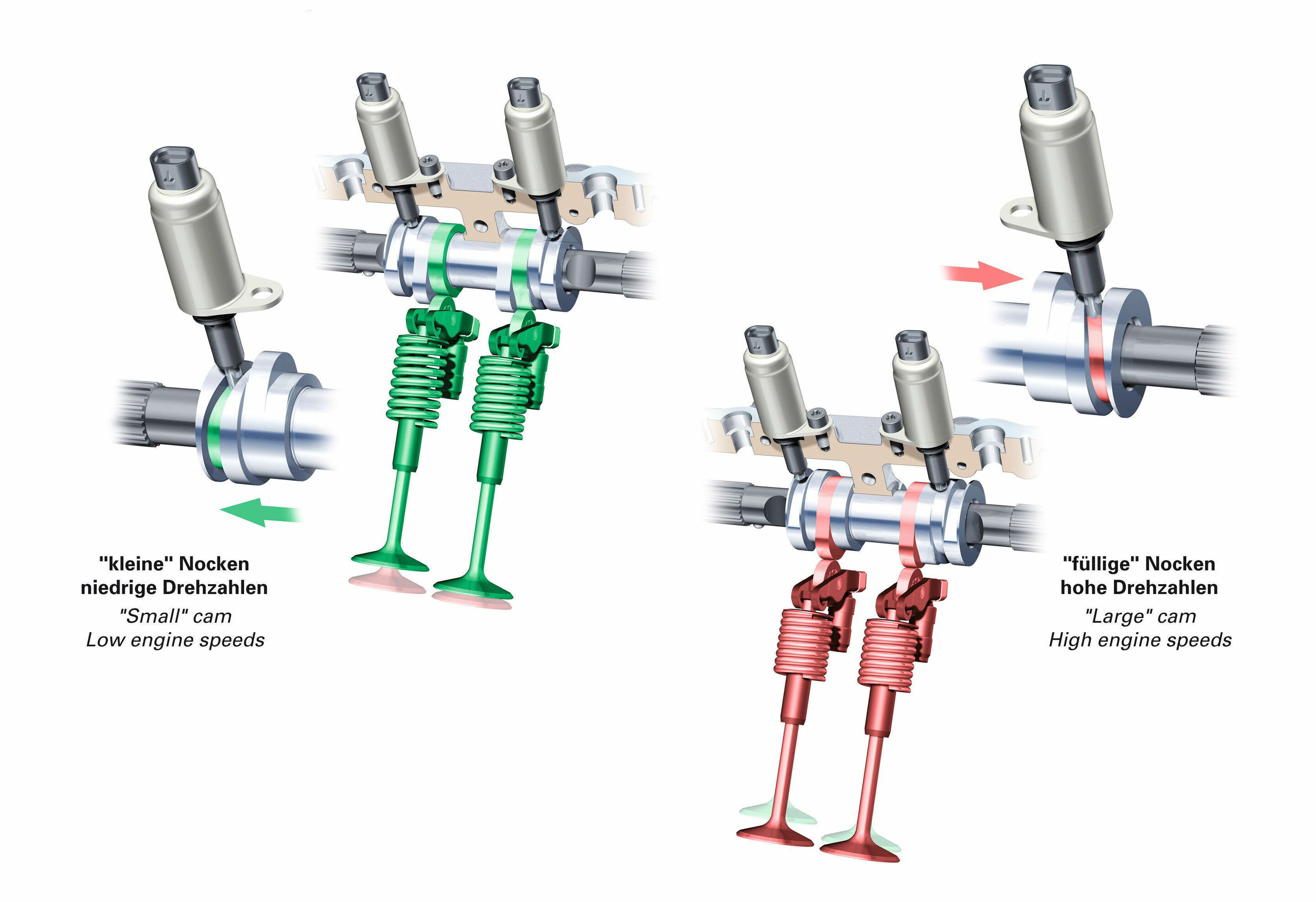

Audi valvelift system (AVS)

The Audi valvelift system (AVS) is a technology for variable valve control. Audi uses it for different purposes in different engines, but the working principle is the same for all engines: Sleeves are mounted onto the camshafts which have cam profiles with varying contours. Electromagnetically actuated pins push the sleeves axially several millimeters by engaging into spiral-shaped slots on their outer contours. Either the low cam or the high cam opens the valve, depending on the position of the sleeve.

In the new 3.0 TFSI, the 2.9 TFSI and the 2.0 TFSI with 140 kW (190 hp), the AVS acts on the intake valves. It adjusts their lift and timing (opening duration) over two levels according to engine load and speed, and thereby controls the amount of air that is inducted. In part-load operation, the lift and opening duration are relatively small. The throttle valve can remain wide open, and this largely eliminates throttle losses. At higher loads, the AVS switches to a higher lift and later valve closing. The combustion chamber charge increases in size, and the engine can aspirate air freely for more power and torque.

In some four-cylinder gasoline engines and in the 2.5 TFSI with its five cylinders, the AVS varies the lift of the exhaust valves. This reduces flushing losses in the combustion chamber and ensures optimal flow of exhaust gas to the turbocharger, particularly in the low rpm range. The results are dynamic engine response and increased torque.

In the 1.4 TFSI the system serves to deactivate half of the cylinders at a moderate driving pace, which reduces fuel consumption. The deactivated cylinders largely run without losses, like compressed gas springs, while the active cylinders operate at the better efficiency levels found in higher load regions.

The 4.0 TDI presents another variant of this technology. Here, the Audi valvelift system manages the two turbochargers, which are switched according to a strategy based on stages. The exhaust gases, which each cylinder discharges from its two exhaust valves, flow through separate channels within a dual-flow manifold system. Each channel supplies one of the two turbochargers. At low loads and engine speeds, the AVS keeps one of the two exhaust valves closed so that the full exhaust flow reaches what is referred to as the ‘active’ turbocharger. With increasing engine speed, the second exhaust valve opens, and this activates the second turbocharger as well. Other AVS units are mounted on the intake camshafts; they serve to regulate the amount of intake air charge in the combustion chambers as needed.

B-cycle process

The B-cycle combustion process is an efficiency technology for gasoline engines by Audi. It has been specifically designed for the part-load range, which is the predominant operating mode during normal driving. Essentially, the method is comparable with what is known as the Miller cycle. However, Audi engineers have advanced it decisively – by adding increased compression, turbocharging and the Audi valvelift system (AVS). The results: During a moderate style of driving, drivers experience the fuel-efficiency advantages of a small displacement engine; while driving in a sporty style, on the other hand, they benefit from the dynamic performance of a large engine.

The B-cycle combustion process is used in three TFSI engines: in a variant of the 2.0 TFSI, in the 3.0 TFSI V6 and in the 2.9 TFSI with its biturbo charging. The core characteristic of the combustion process is an unusually short opening time during induction in part-load. The intake valves of the V6 TFSI already close at a crank angle of 130 degrees – well before the pistons reach bottom dead center (BDC). This and increased pressure in the induction manifold reduce throttle losses. The amount of inducted fresh air remains relatively small; accordingly, the compression phase begins later when the piston travels upward after the BDC point. This permits a high geometric compression ratio of 11.2:1 – the combustion takes place with a relatively small combustion chamber volume. Compared to the short compression phase, the expansion phase is lengthened significantly. The result is greater engine work output at the same fuel consumption, which significantly boosts efficiency.

In the classic Miller cycle, the reduced cylinder charge is disadvantageous to torque and power output. Audi has neutralized these effects by implementing turbocharging and the two-stage Audi valvelift system (AVS). At higher load and engine speed, the AVS of the V6 TFSI closes the intake valves later – the opening time is increased to 180 degrees crank angle in the 3.0 TFSI and to 200 degrees in the 2.9 TFSI. Simultaneously, valve lift increases from 6.0 to 10 millimeters. The cylinder charge also increases considerably – the engine revs up powerfully and delivers an impressive output.

In the V6 engines, central placement of the injector in the combustion chamber is an important component of the B-cycle combustion process. In the area around the intake valves, this enables a geometry which, in interaction with the inlet ducts, enables targeted swirl of the gas charge, thereby optimizing combustion.

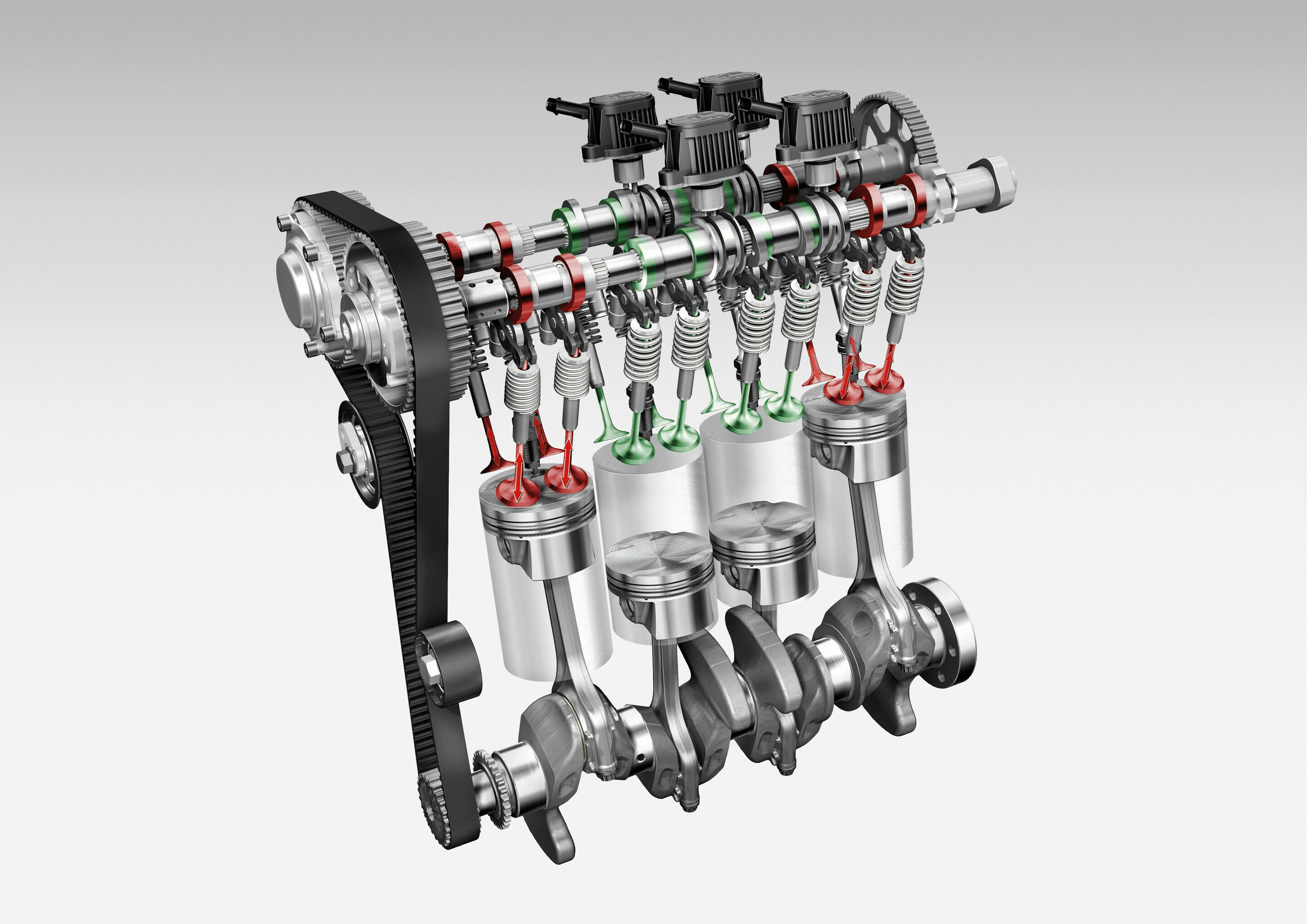

Cylinder on demand

The efficiency system cylinder on demand (COD) involves cylinder deactivation. Audi implements it in some of its engines – the 1.4 TFSI and the 5.2 FSI. At low to medium load and engine speed, the system deactivates half of the cylinders in the upper gears. In COD operation, the four-cylinder engine runs with two cylinder. In the V10 one of the cylinder banks is deactivated.

The COD system shuts off fuel injection and ignition, and in the TFSI it also closes the valves thanks to the Audi valvelift technology. Electromagnetically extending pins slide the cam units – these are sleeves which have two different cam profiles – several millimeters onto the camshafts by engaging into the spiral contours on the outsides of the cam units. When the profiles known as ‘zero-lift’ profiles are rotating over the valves, they do not actuate the valves, and the valve springs keep them closed.

The switching process takes just milliseconds, and the driver virtually does not even notice it. In the active cylinders one and four, the operating points shift to higher load, which boosts efficiency, while the deactivated cylinders follow – essentially with no losses – like compressed gas springs at low pressure. When the driver presses the accelerator pedal, the deactivated cylinders are reactivated. The COD system can reduce fuel consumption by several tenths of a liter per 100 kilometers in real-life use by the customer.

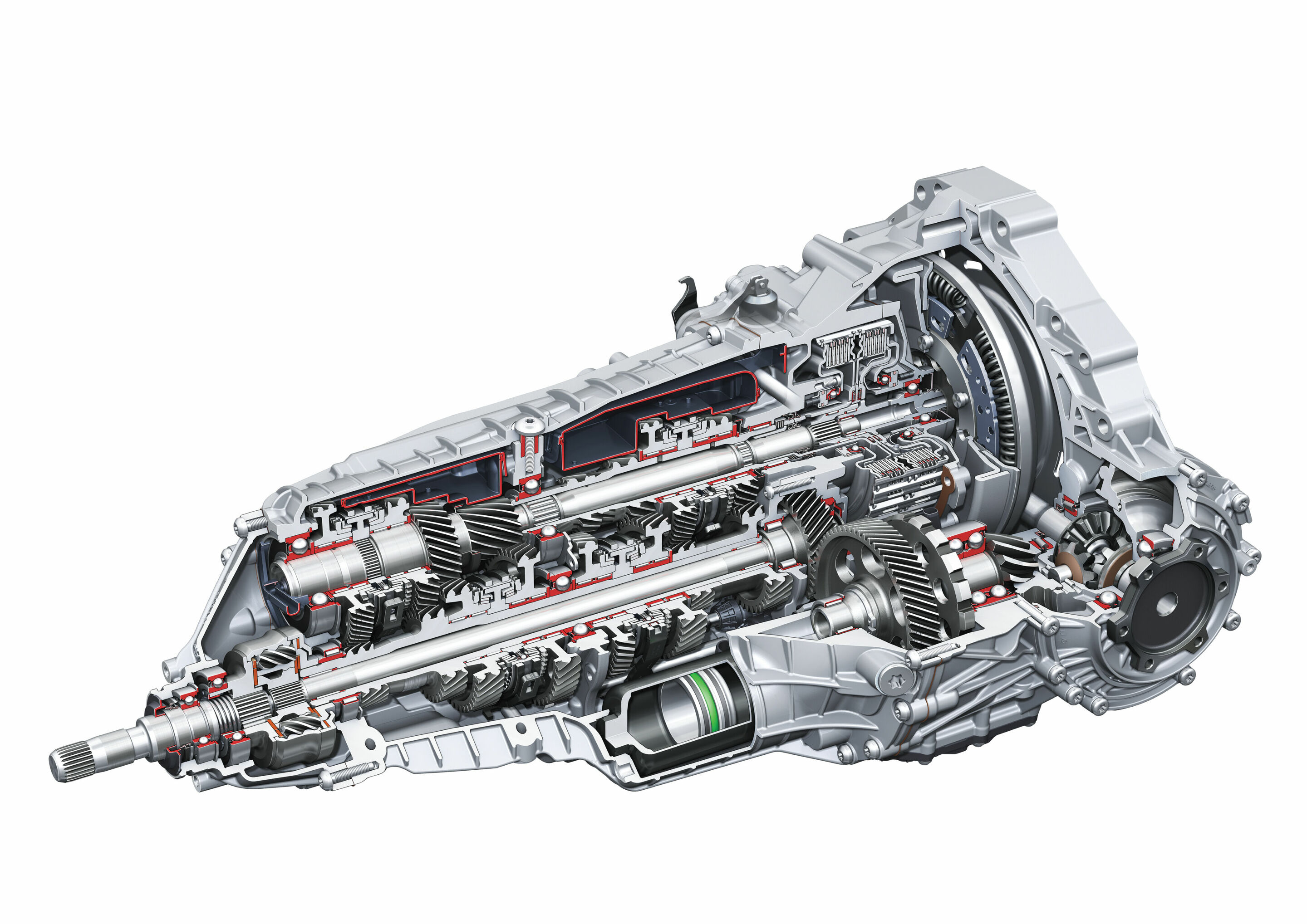

S tronic dual-clutch transmission

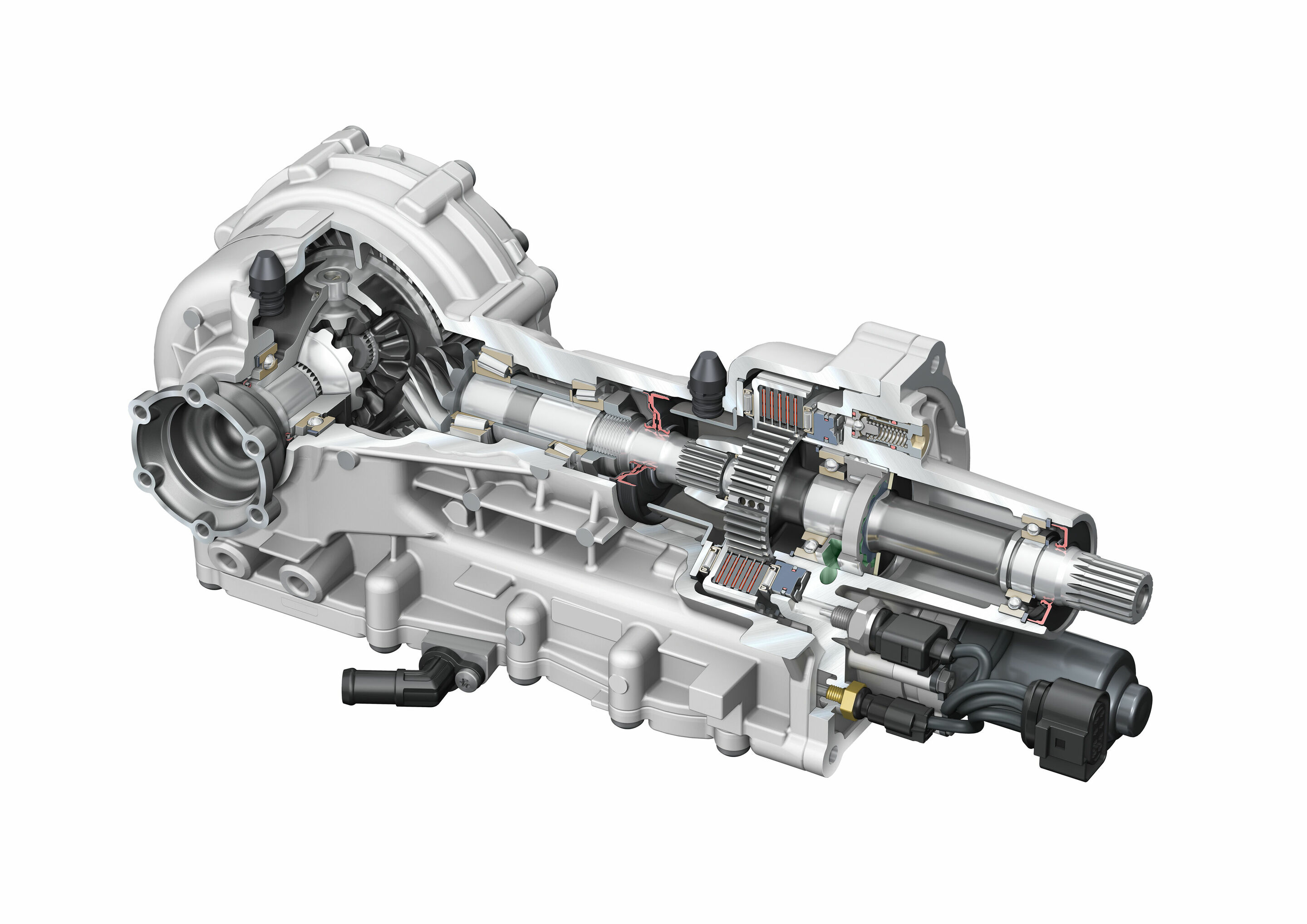

The S tronic dual-clutch transmission combines the convenience of an automatic transmission with the efficiency of a manual transmission. It is available over a broad range of models in different versions – with six or seven gears. Audi has developed a special version of the seven-speed S tronic for longitudinally mounted engines. In this version, the gear wheels for all gears are arranged sequentially on one output shaft. The four variants for transverse mounted engines, on the other hand, have a layout with two output shafts. This enables compact construction. The S tronic for transverse engines is available with six or seven speeds; the seven-speed variant has three versions. There are also three versions for longitudinally mounted engines, one of which is designed for pure quattro technology and another as a sporty version that is mounted at the rear of the R8. Which variant works together with which engine is based on what the customer wants in the vehicle and on the torque to be transmitted.

Two multi-plate clutches which operate different gears are integrated in the S tronic. The large K1 clutch transmits engine torque via a solid shaft to the gear wheels for the odd-numbered gears 1, 3, 5 and 7. A hollow shaft rotates around the solid shaft. It is connected to the K2 clutch, which is either in parallel to the K1 clutch or inside of it. This K2 clutch operates the even-numbered gears 2, 4 and 6 as well as reverse gear. Both transmission subunits are continually active, but only one is connected to the engine at any given time. For example, when the driver accelerates in third gear, the fourth gear is already engaged in the second transmission structure. The shifting process takes place as the clutch changes – K1 disengages while K2 engages. This takes just a few hundredths of a second, and they are executed with nearly no interruption of propulsive power. The S tronic shifts so dynamically, fluidly and comfortably that the gear shift is hardly perceptible to the driver.

The mechatronics module, a compact and robust unit, contains the electronics together with the hydraulic actuator units. Its control concept makes it possible to vary the speed of the gear shift and precisely control the necessary force. The multi-plate clutches are managed with maximum precision – the seven-speed S tronic also works in stop-and-go traffic and is very sensitive in maneuvering.

The seven-speed S tronic can be used in different ways. The automatic mode offers the D (Drive) and S (Sport) programs. Drivers can use the selector lever or shift paddles on the steering wheel to shift themselves. Another feature for the high-performance models is Launch Control, which fully exploits the vehicle’s acceleration potential when starting off from a stop. The sportiest seven-speed S tronic for the longitudinally mounted engines can handle engine speeds up to 9,000 rpm.

In all variants, the S tronic offers many strengths: a high level of efficiency, intelligent management and a large spread with high gears that have long gear ratios. Consequently, the high-tech transmission is able to improve fuel economy compared to a manual gearbox in many cases. Its two dry clutches operate without their own oil supply, which further boosts efficiency. All variants of the S tronic are combined with the start-stop system from Audi. The latest S tronic for longitudinally mounted engines offers – in addition to an innovative pressure reservoir system – shift-by-wire technology, which is a prerequisite for numerous assistance systems that culminate in piloted driving.

Electric all-wheel drive

The electric all-wheel drive combines the efficiency of a single-axle drive with the driving dynamics and traction of an all-wheel drive. It ensures the continuous and fully variable regulation of the ideal distribution of drive torque between the two axles. It takes just 30 milliseconds or so from the system detecting the driving situation and the torque from the electric motors kicking in – much faster than with conventional quattro technology. The reason is that with the electric all-wheel drive a mechanical clutch is not engaged but electricity is simply distributed. And that takes just a fraction of a second. So even with sudden changes in the coefficients of friction and extreme driving situations the full quattro performance is guaranteed.

In most cases, the Audi e-tron tends to use its rear electric motor to achieve the highest efficiency. For reasons of efficiency, the drive torque is generally distributed with a rear-axle bias. If the driver demands more power than the rear electric motor can supply, the electric all-wheel drive redistributes torque as required to the front axle. This also happens predictively even before slip occurs in icy conditions or when cornering fast, or if the car understeers or oversteers. In conjunction with the wheel-selective torque control, the electric all-wheel drive offers high traction in different weather conditions and on disparate terrain.

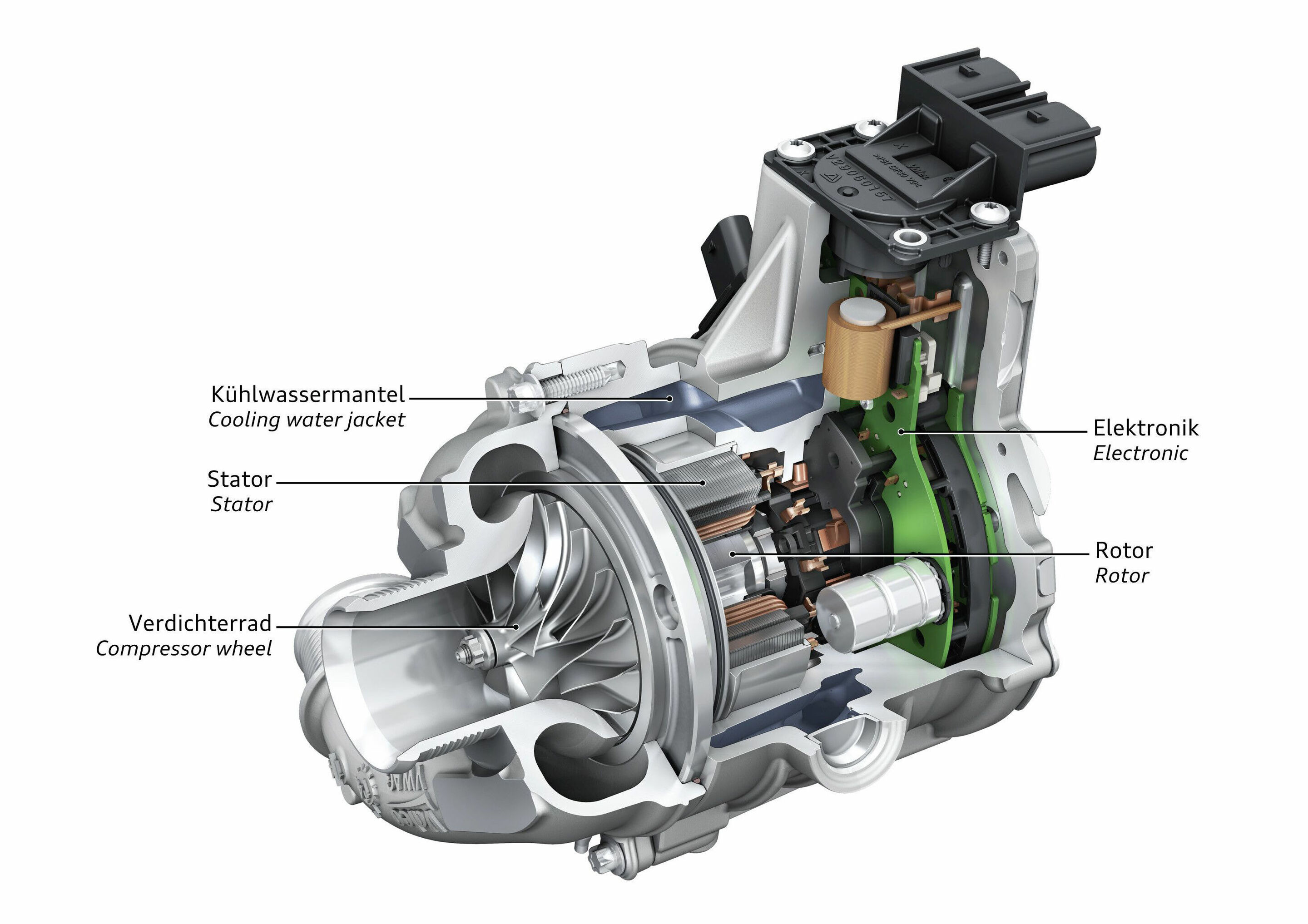

Electric powered compressor

The electric powered compressor (EPC) supplements the work of the turbocharger(s) during start-up and acceleration at a very low engine speed – i.e. whenever there is insufficient power for strong torque build-up in the exhaust stream. It therefore enables instant responsiveness and dynamic start-off performance from standstill. Sporty drivers will appreciate the power for passing and immediate power delivery when exiting a curve. In a relaxed style of driving, EPC technology avoids unnecessary downshifts and thus keeps rev levels and fuel consumption low.

The EPC operates with a constant voltage of 48 volts. It is situated in the intake air path behind the intercooler and is active in the following two operating statuses: During start-up, the bypass closes and the EPC precompresses the air flow. This increases the filling of the combustion chamber. When driving, if the load requirement from the accelerator is high while the amount of energy available in the exhaust gas is low, the bypass flap closes and the intake air flows into the EPC, where it is compressed for the second time. A compact electric motor with an output of up to 7 kW accelerates the compressor wheel of the EPC to up to 70,000 rpm in approximately 250 milliseconds.

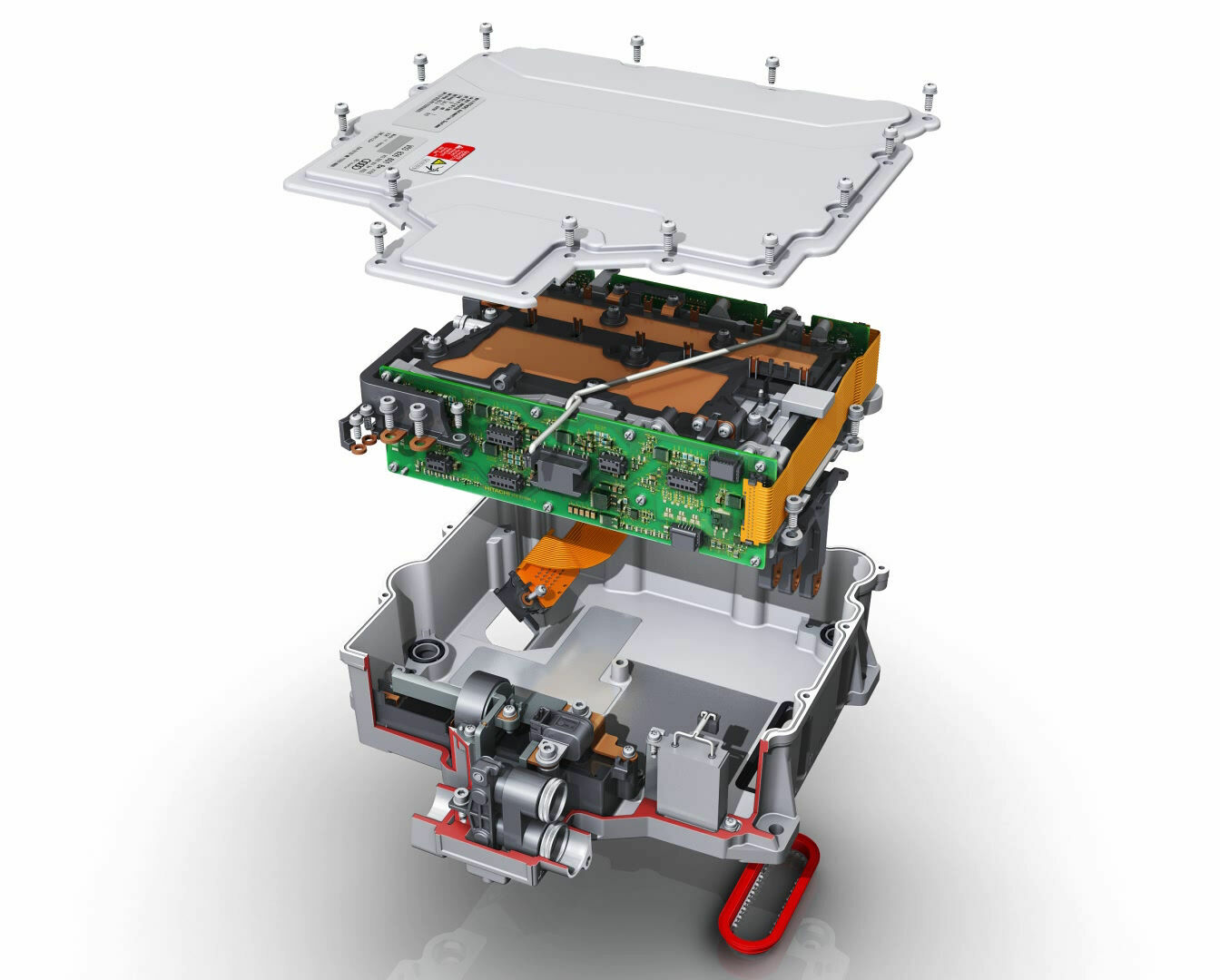

Power electronics

The high-voltage battery delivers direct current; the electric motors use three-phase current, which is why every electric motor is connected to a power electronics module that converts the electricity. With a volume of 5.5 liters (0.2 cu ft) and weighing eight kilograms (17.6 lb), the power electronics modules of the Audi e-tron are very compact. Both include a microcontroller for controlling the electric motor and are integrated into the thermal management system for the electrical units. They are extremely dynamic, reading sensor data 10,000 times per second and outputting current values for the electric motors.

Manual transmissions

All transmissions from Audi are state-of-the-art, and this applies to the manual transmission as well. They are distinguished by their high levels of efficiency.

The manual six-speed transmissions in the A4, A5 and A6 model series, and in the Q5, have been redeveloped compared to the transmissions used in previous models. Much of the transmission case is made of ultra-light magnesium – the share of this material depending on the torque class. A spur gear stage replaces the shaft to the front differential. This brings major advantages with respect to friction and space requirements. Weight is further reduced by open gear wheels, hollow shafts and a smaller clutch, which are all sized according to the torque class of the transmission. Overall, the transmission has been made 16 kilograms (35.3 lb) lighter.

The manual transmissions in the A4, A5, A6 and Q5 that are used in conjunction with four-cylinder engines with maximum torques up to 400 Nm (295.0 lb-ft) also have very efficient injection lubrication. This has further improved their efficiency – in both front-wheel drive units and in the quattro ultra transmissions that have also been redeveloped.

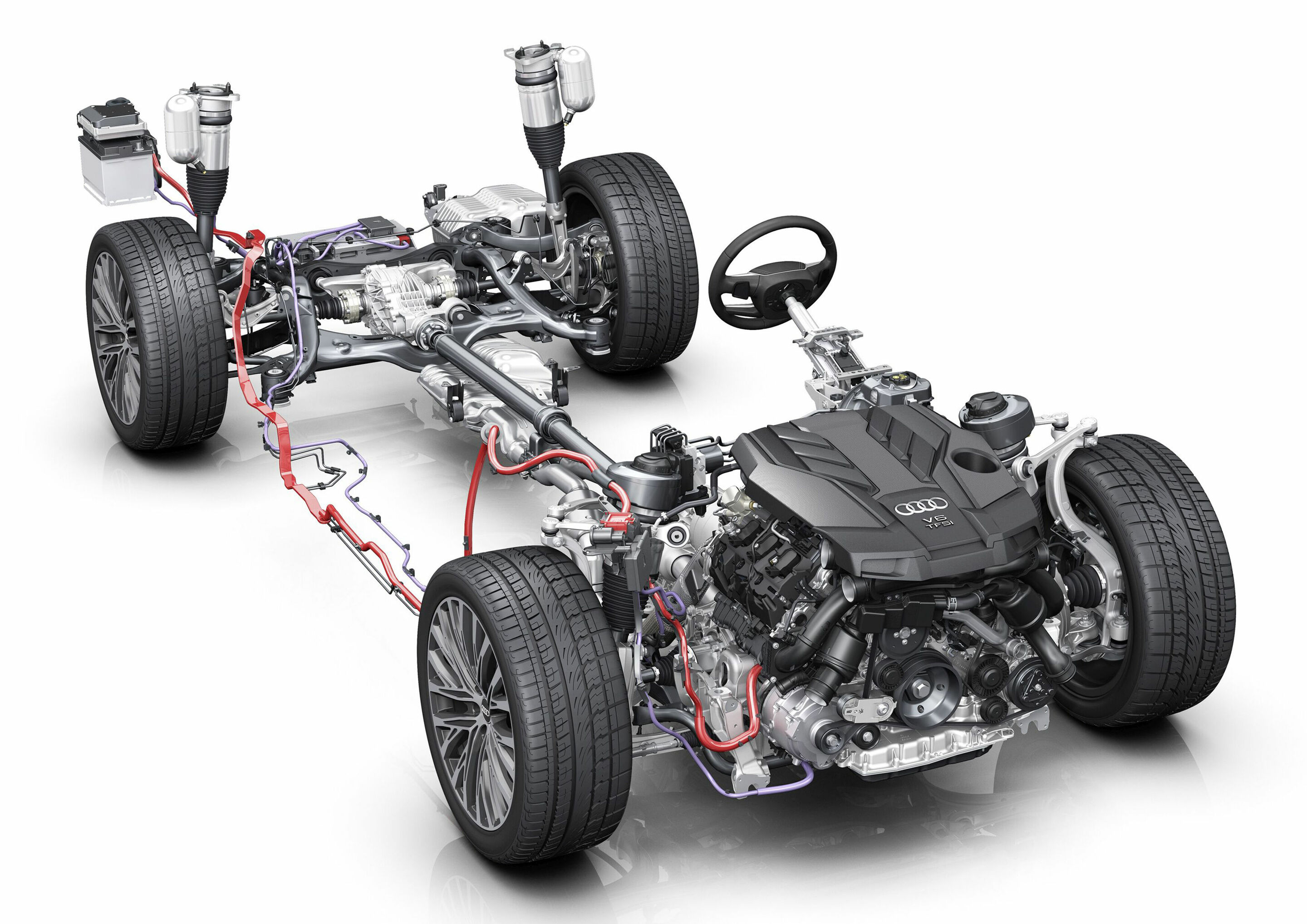

Mild hybrid technology

In mid-2017, the new mild hybrid electric vehicles (MHEVs) began to enter the product line-up and are appearing in a broad range of models. The new technology is well-suited for both diesel or gasoline engines and can reduce consumption in a V6 gasoline engine by up to 0.7 liters per 100 kilometers (0.2 US gal per 62.1 mi) in real-life driving conditions.

Audi offers two variants of MHEV drive systems. For the four-cylinder engines, they are based on the familiar 12-volt electrical system. However, the six- and eight-cylinder engines are equipped with a new 48-volt system that serves as the main vehicle electric system. A compact lithium-ion battery stores the energy. A water-cooled belt alternator starter (BAS) is mounted to the combustion engine’s front end and is connected via a heavy-duty V-ribbed belt to the crankshaft. During braking, the BAS can recover up to 8 kW of power and feed the energy into the battery. A DC/DC converter connects the 48-volt system and 12-volt electrical system.

The 48-volt MHEV technology offers exceptional convenience and efficiency. When drivers take their foot off the accelerator pedal at a driving speed from 55 to 160 km/h (34.2 to 99.4 mph), the car can coast for up to 40 seconds with the engine shut off completely. When coasting at low speeds, the start-stop phase already begins at 22 km/h (13.7 mph). The drive management system utilizes information from the navigation map and on-board sensors to evaluate whether coasting is more fuel-efficient or recuperation. It selects recuperation, for instance, if the efficiency assistant detects a vehicle driving ahead. In the braking phases, the BAS assists in braking and can feed the recovered electrical energy into the 48-volt storage unit or use it directly for electrical consumers.

When the driver presses the accelerator pedal again after a coasting phase or a stop, the BAS restarts the combustion engine. The conventional pinion starter is only used for the initial starting operation when the engine oil is still cold and a higher starting torque is required. The BAS start is controlled based on load demands by the driver. For example, if the air conditioner is activated and requires an engine start while the vehicle is stopped, the engine is restarted very comfortable. The same is true if the driver releases the brake pedal in a start-stop phase to rejoin other vehicles in traffic. If the driver presses the accelerator pedal further, signaling a wish for significant acceleration, the engine start is executed as quickly as possible. In addition, there is what is known as the predictive convenience start. Here, the engine is started as soon as the car ahead starts moving, even if the driver is still pressing the brake pedal.

The functional principal of MHEV technology that utilizes a 12-volt electrical system is the same as with 48 volts. However, the coasting phases, recuperation output and the CO2 savings are somewhat reduced.

quattro permanent all-wheel drive

Throughout its model range, Audi offers a very wide variety of car concepts – and quattro technology is equally multifaceted.

- Modular longitudinal platform: the self-locking center differential

In Audi models with a longitudinally mounted front engine, the heart of the quattro drivetrain is a self-locking center differential. It is configured as a purely mechanical planetary gear with no time lag. A hollow wheel surrounds a sun wheel. Between the two, cylindrical planetary wheels turn, which are connected to the rotating housing. In regular driving operation, 60 percent of the drive torque flows to the rear axle via the hollow wheel, which has a larger diameter, and its associated output shaft. 40 percent goes to the front axle via the smaller sun wheel. This asymmetrical, dynamic torque distribution results in sporty handling that emphasizes rear propulsion. Oblique splines produce axial forces immediately when torque is transfered by the differential. These forces act on friction discs to produce a locking torque that diverts the torque to the wheels with the better traction.

In its latest form, the center differential can divert 70 percent of the torque to the front, or up to 85 percent to the rear. The high locking values enable a clearly defined torque distribution and highly precise interaction with control systems such as the ESC and wheel-selective torque control. For even greater dynamics and driving safety, top-of-the-line Audi models based on the modular longitudinal platform can also be equipped with a sport differential.- Audi A4

- Audi A5

- Audi Q5

- Audi A6

- Audi A7

- Audi Q7

- Audi A8

- Modular transverse platform: the electro-hydraulic multi-plate clutch

For compact models with a transverse-mounted engine, Audi uses a quattro drivetrain featuring an electronically controlled multi-plate clutch with hydraulic actuator. It is mounted at the end of the propshaft before the rear differential to optimize weight distribution. Inside the clutch is a package of metal friction rings mounted in pairs one behind the other. One ring of each pair is permanently meshed with the clutch basket, which rotates with the propshaft. The other ring of each pair is connected to the shaft leading to the rear differential.

The all-wheel drive software constantly calculates the right torque distribution between the front and rear axles based on numerous data. When there is demand for torque, the highly efficient electric axial piston pump builds up as much as 40 bar of hydraulic pressure within just a few milliseconds. It presses the friction plates together, which enables variable transmission of the drive torque to the rear axle. The electronically controlled multi-plate clutch guarantees the best possible traction, driving dynamics and driving safety while delivering dynamic handling with actively controlled torque distribution.- Audi A1

- Audi Q2

- Audi A3

- Audi Q3

- Audi TT

In the sporty models with transverse-mounted engine, the management of the multi-plate clutch is configured with a focus on dynamics. Here its special control philosophy puts considerable emphasis on parameters relevant to driving dynamics; at the same time in some models it is based on the Audi drive select mode that is active and on the electronic stabilization control (ESC). This results in more frequent and pronounced torque distribution favoring the rear axle, which further adds to sporty handling. In sport mode, or when ESC is disabled, the management permits controlled drifts on road surfaces with low friction coefficients. In a more relaxed mode of driving, on the other hand, it is possible to fully disengage the clutch temporarily in some models to save fuel. As soon as the driving state changes, the quattro drive is reactivated.

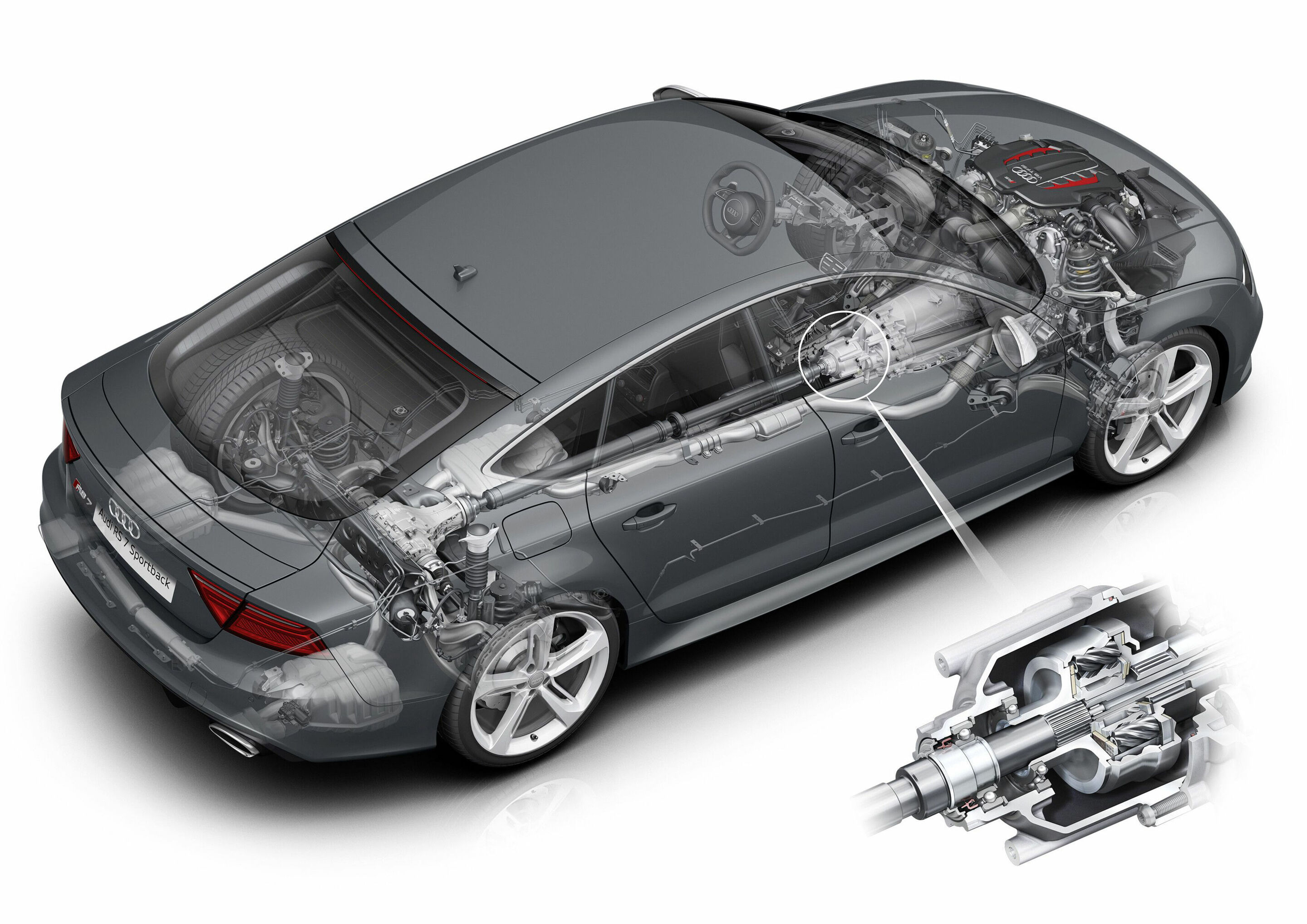

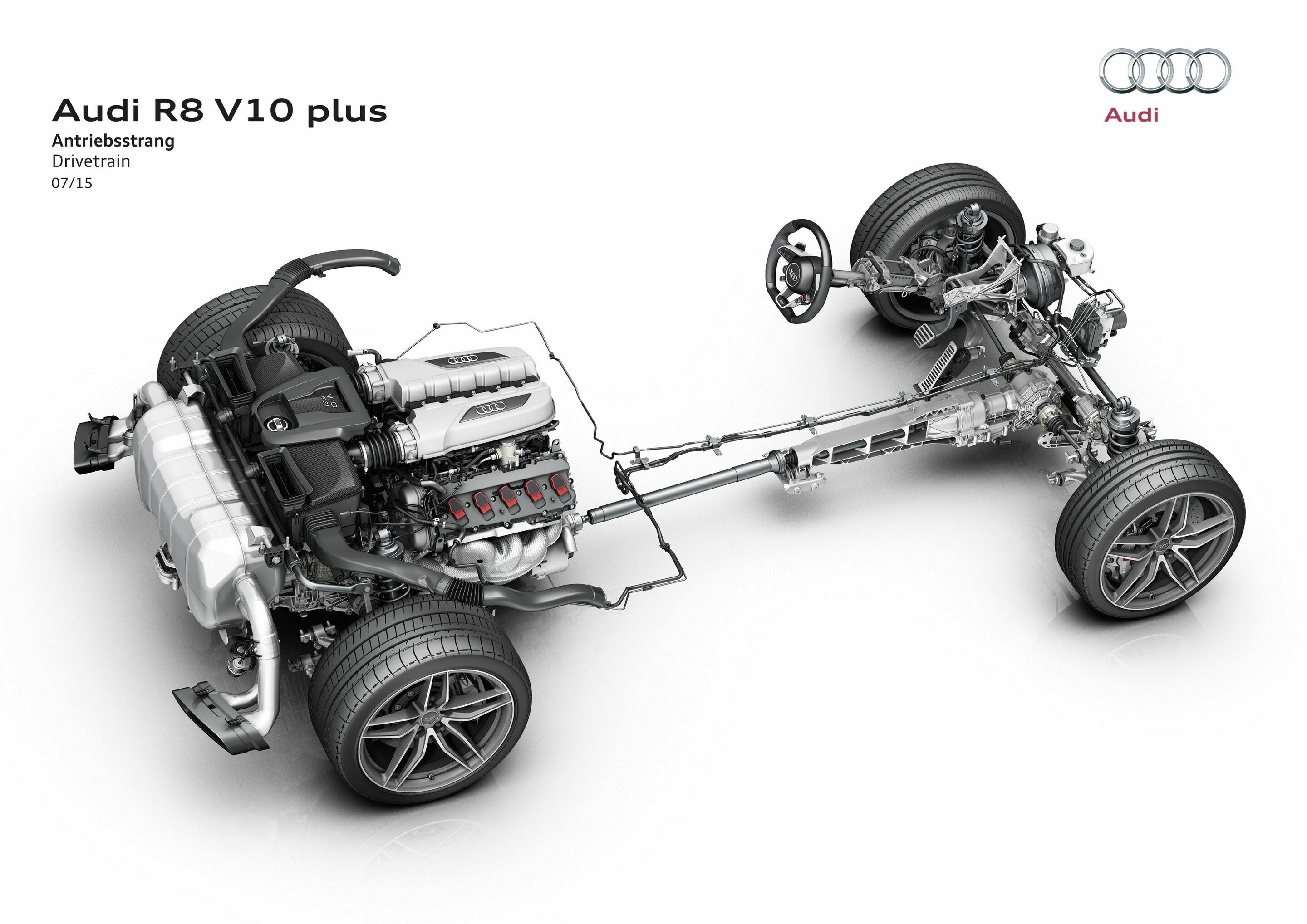

- Audi R8: Actively controlled front differential

In the Audi R8, the seven-speed S tronic with its integrated rear differential and limited-slip differential is located behind the engine. The electro-hydraulic multi-plate clutch integrated in the front differential transmits torque to the front wheels via a propshaft within just a few milliseconds. It can distribute torque between the two axles fully variably. The combination of a high-performance transmission mechanism and all-wheel drive software tailored to a mid-engine sports car enables driving dynamics that attain an unprecedented balance between stability and agility.

The all-wheel drive software continuously computes the ideal distribution of torque to the axles as a function of the driving situation, driver inputs and ambient conditions. Up to 100 percent of the power can flow to the front or rear axle, for instance. quattro management is integrated into the Audi drive select driving dynamics system which offers the four modes comfort, auto, dynamic and individual. In the performance mode, it also offers programs for dry, wet and snow. These programs adapt driving dynamics parameters to the specific grip conditions of the road surface.The mechanical rear differential further improves traction and driving dynamics. It has a locking effect of 25 percent during engine traction operation and 45 percent during engine overrun. It is precisely tuned for the dynamic character of the Audi R8 and the actively controlled quattro drive. This results in turn-in behavior that practically eliminates understeer.

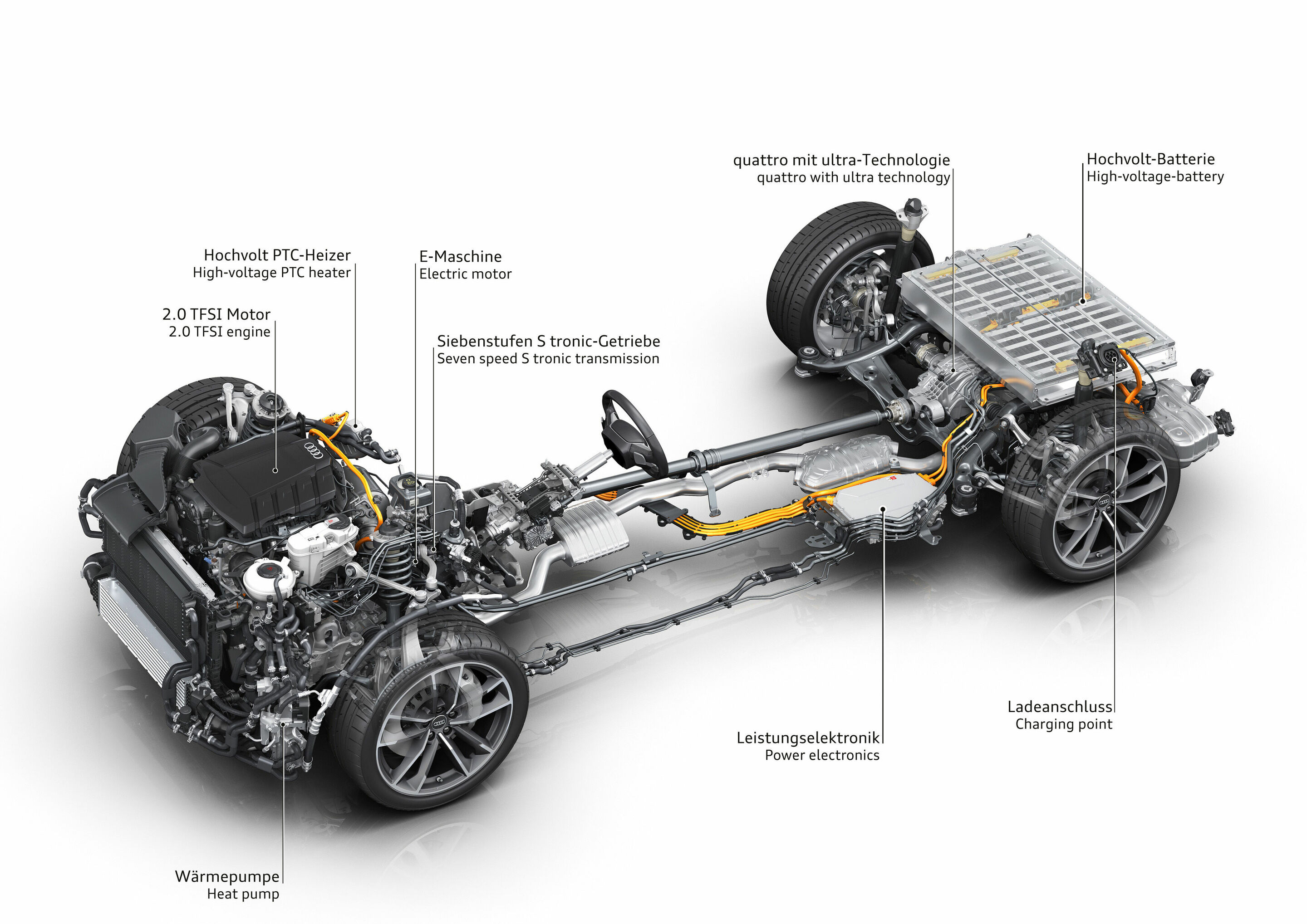

Plug-in hybrid technology

Audi has been offering models as plug-in hybrids since as far back as 2014. Plug-in hybrid is the colloquial term for a plug-in hybrid electric vehicle, abbreviated PHEV. Traditionally, a powertrain is called a hybrid whenever two propulsion technologies – such as an IC engine and a motor and the respective energy storage systems – are combined in one vehicle.

In automotive engineering, the combination of an IC engine with an electric motor has become established for PHEV models. A typical characteristic of so-called parallel hybrids combining an IC engine and an electric motor in one powertrain unit is that the electric motor can either be used as the sole, locally emission-free traction motor or assist the IC engine in both part load operation and with extra boost capacity during stages of higher acceleration. The electric motor also serves as a generator for recuperation, converting kinetic energy into electric energy and storing it in a lithium-ion battery. On a plug-in hybrid, the battery can be charged externally at a charging station or power outlet.

In designing plug-in hybrid models, Audi focuses on three objectives: long and frequent electric driving segments plus low overall energy consumption, easy charging management and high suitability for everyday use.

The electric driving experience, for one, is ensured by powerful electric motors enabling all-electric driving across a wide speed range in various driving situations. Smart powertrain management – designed for maximum efficiency and customer comfort – provides the basis for frequent and sustained electric driving. In addition to the automatic selection of hybrid mode, drivers have the choice between “EV” and “Hold” modes. In “EV” mode, the car, subject to the battery’s relevant state of charge, is propelled strictly by electric power as long as the driver does not exceed a variably perceptible pressure point in the accelerator pedal. “EV” mode is the default setting anytime the car is started. In “Hold” mode, the powertrain management system controls the powertrain so that the existing charge status of the battery is maintained, for instance to enable subsequent all-electric driving in urban areas. Even so, this mode also includes fully electric driving segments.

In addition, by using the commonly known switch of the Audi drive select driving dynamics system, the driver can choose between “comfort,” “efficiency,” “auto” and “dynamic” modes and thus influence the setup of the powertrain, suspension and steering systems. During acceleration, depending on the setting, the thresholds change at which both propulsion systems start working together or the electric motor provides boost and thus maximum torque. In “dynamic” mode, the electric motor increasingly assists the IC engine with its electric boost capacity for maximum driving dynamics.

The sophisticated powertrain management substantially contributes to Audi’s PHEV models enabling long electric driving segments combined with moderate battery sizes. The Predictive Efficiency Assistant (PEA) and the Predictive Operating Strategy (POS) are the two core technologies of the powertrain management system. The Predictive Efficiency Assistant – known from Audi models with conventional powertrains – situationally controls the propulsion and recuperation behavior to suit immediate and obvious vehicle information such as predictive route data supplied by the navigation system or the front camera. The Predictive Operating Strategy controls the propulsion and recuperation behavior along the entire route. During active route guidance the POS analyzes route information along the travel distance such as traffic jams and types of roads like backroads and freeways. The area surrounding the destination is included in planning powertrain management as well. The objective pursued by route planning is to maximize electric driving in urban areas and to arrive at the planned destination with a near-empty battery. The reason is that as much electric energy as possible should be used in order to recharge the vehicle after arrival at the destination.

The active accelerator pedal that assists drivers in maximizing the efficiency of their driving style by providing haptic feedback is linked to powertrain management as well. It indicates when drivers are leaving the all-electric driving stage via a pressure point in the accelerator pedal. Based on the information from the Predictive Energy Assistant, it also prompts drivers to lift for coasting or recuperation.

The electric motor handles all minor decelerations – in other words, the majority of braking events in everyday driving. In moderate braking events, it shares deceleration duties with the hydraulic wheel brakes, which are used alone only beyond a deceleration level of 0.4 g. A complex vehicle setup results in a nearly imperceptible transition between the generator brake of the electric motor and the conventional wheel brake (“blending”), combined with a carefully defined and constantly identical pressure point in the brake pedal.

The PHEV models are charged at 400-volt three-phase AC chargers with a capacity of up to 7.4 kW, which takes around 2.5 hours. This charging time is ideal for the typical user patterns of PHEV customers. It enables easy and fast charging of the car once or twice a day, either at home or additionally at work. Fully charging the battery on a 230-volt household outlet takes about 6.5 hours.

Audi ensures high suitability for everyday use of its PHEV models by providing ample space as well as high variability and usability. The batteries are installed in a compact way underneath the trunk floor – without sacrificing a lot of space and without including a step. For all PHEV models, except the Audi A8, operation with a trailer hitch continues to be possible.

Audi offers plug-in hybrid models both in the compact and full-size car class. On the mid-size and full-size models A6, A7, A8, Q5 and Q7, power is transferred to the road via all four wheels – resulting in maximum traction even in poor road and whether conditions as well as high agility for a sporty driving style.

The battery system consists of liquid-cooled lithium-ion cells. The power electronics system, which is integrated in the cooling circuit as well, converts the direct current of the high-voltage battery into three-phase alternating current for the electric motor. During recuperation the process is reversed. Audi’s mid-size and full-size PHEV models, except for the Q7, use a complex thermal management system controlling the high-temperature circuit for the IC engine, the transmission and accessories as well as the low-temperature circuit for the battery, the charger, the electric motor and the power electronics. Integrated in the thermal management system is a heat pump in which electrical energy is converted into thermal output. The heat pump is coupled with the coolant circuit of the air conditioning system and uses the waste heat of the high-voltage components for fast and efficient temperature control of the car’s interior.

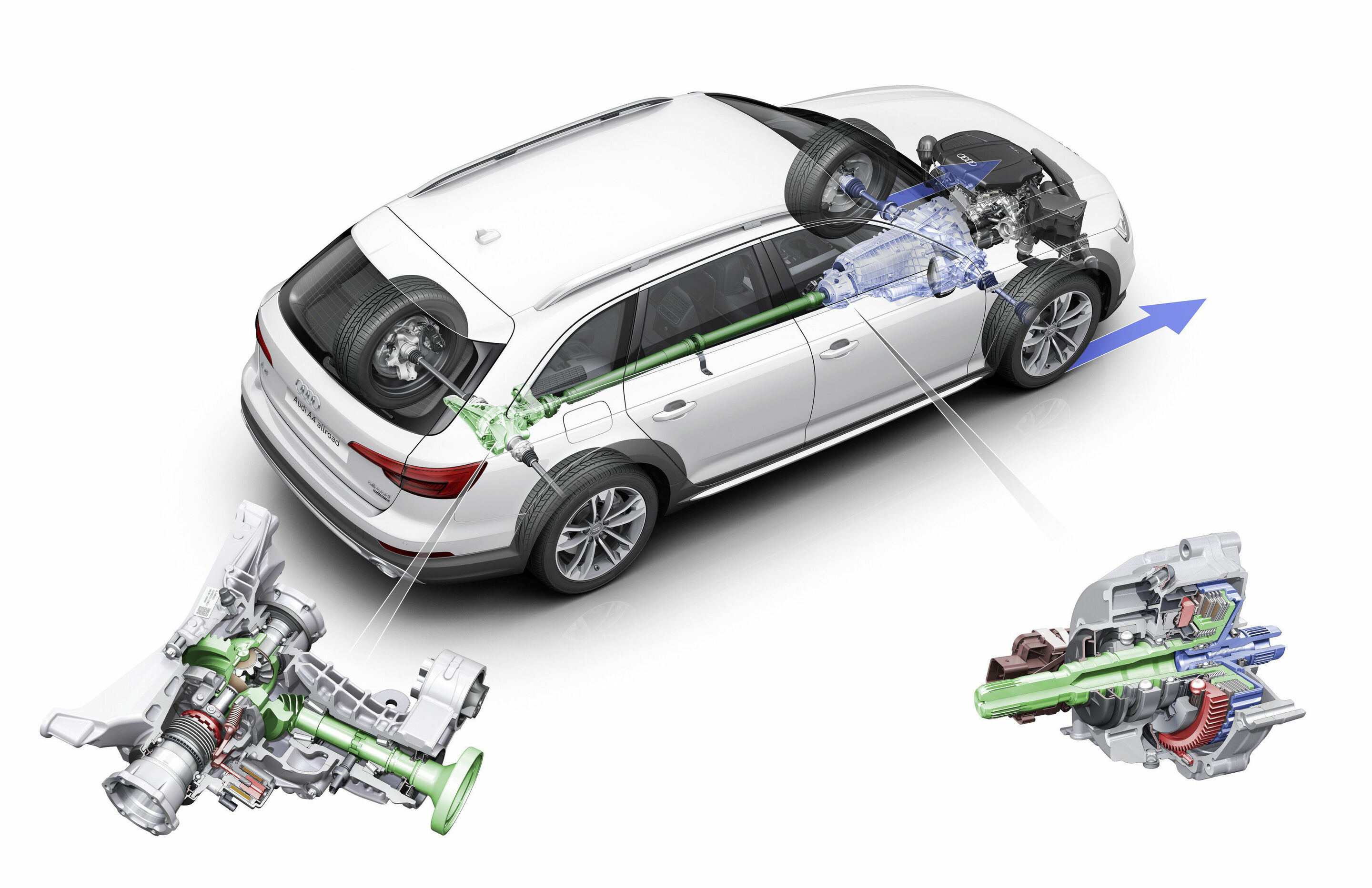

quattro drive system with ultra-technology

quattro with ultra technology combines driving dynamics and safety with high efficiency.

This is all attributable to combining the newly developed all-wheel drive components with a sophisticated operating strategy and a torque split that is perfectly matched to the car. This optimized all-wheel drive system engages only when required. Despite this, the drive system exhibits no perceptible differences from permanent systems in terms of traction and driving dynamics.

During moderate driving, quattro with ultra technology enjoys all the advantages of front-wheel drive. All-wheel drive remains permanently available, however, and is there immediately when needed. The control system for the quattro powertrain is comprehensively networked. It acquires and evaluates data – in ten millisecond cycles – such as the steering angle, transverse and longitudinal acceleration and engine torque.

During moderate driving, quattro with ultra technology enjoys all the advantages of front-wheel drive. All-wheel drive remains permanently available, however, and is there immediately when needed. The control system for the quattro powertrain is comprehensively networked. It acquires and evaluates data – in ten millisecond cycles – such as the steering angle, transverse and longitudinal acceleration and engine torque.

All-wheel drive is generally activated predictively, i.e. in anticipation of the need for it. For example, the control unit computes the point when the inside front tire will reach the limit of grip during fast cornering. The calculation is completed roughly half a second in advance, and all-wheel drive is activated just before the wheel reaches the traction limit. With reactive activation – which rarely occurs in practice – the system reacts to sudden changes in the coefficient of friction. These changes might occur, for example, when the wheels go from dry asphalt to a sheet of ice. Thanks to the very short switching times, full quattro performance is ensured even in these extreme situations.

The concept with two clutches in the powertrain gives quattro with ultra technology a key efficiency advantage over the competition. When the system changes to front-wheel drive, the front clutch – a multi-plate clutch at the transmission output – disconnects the propshaft. A decoupling clutch also opens in the rear differential. It shuts down the rotating components that cause the most drag losses here, such as the large crown wheel running in the oil bath. Despite the additional components, the quattro with ultra technology is nearly four kilograms (8.8 lb) lighter than the previous system.

The quattro with ultra technology has been designed for numerous Audi models with a longitudinally mounted front engine. The system can be used in combination with manual transmissions, such as the S tronic dual-clutch transmission, up to torques of 500 Newton meters (368.8 lb-ft).

Recuperation

Recuperation refers to the use of kinetic energy during deceleration. An electric traction motor in the vehicle turns into a generator when it is pushed and the rotor moves more quickly than the stator’s rotating field. A distinction must be made between coasting recuperation, which takes place when the driver’s foot releases the right-hand pedal, and braking recuperation, when the driver depresses the brake pedal. Coasting recuperation can take place automatically via the predictive efficiency assist. It regulates the deceleration as needed and predictively, for example in relation to the route or vehicles in front. Alternatively, the driver can regulate the degree of deceleration manually using the shift paddles on the steering wheel. During coasting and braking phases, the generator converters the kinetic energy into electric energy and feeds it into the battery. Overall, the Audi e-tron attains up to 30 percent of its range through recuperation.

Rightsizing

Downsizing became the mainstream in engine development with the introduction of TFSI technology – its aim was to continually reduce engine displacement while simultaneously increasing power density. This led to substantial savings in terms of fuel consumption. Rightsizing is a continuation of the conventional downsizing. It enables additional gains in fuel economy in the near full-load region by modified combustion processes and selection of displacement. Innovative technologies are used to achieve this such as the Audi valvelift system (AVS), integration of the exhaust manifold into the cylinder head and a turbocharger with an electric wastegate actuator. They make it possible to design the engines to attain an optimal combination of displacement, power, torque and fuel economy for the required use conditions. The cylinder on demand (COD) system is another example of this. It shuts down four or two cylinders in the part-load region. This solution is a variant of the rightsizing strategy. It aims to attain the right ratio of displacement and charging.