Audi launches initiative for digital factory transformation in Heilbronn

- Goal: Establishment of a world-leading competence network for digital factory transformation and innovation

- Initiative by Audi, TU Munich, Fraunhofer IAO, XL2, Capgemini, AWS and SAP

- Audi Board Member for Production Kössler: “Together with our ‘Automotive Initiative 2025’ partners, we will develop the Neckarsulm site into a leading factory for digital production and logistics within the Group.”

Pooling competence for Smart Production and Logistics: Audi will be collaborating closely in the future with the Technical University of Munich and the Fraunhofer Institute for Industrial Engineering IAO in the area of digitalization at the Bildungscampus of Dieter Schwarz Foundation in Heilbronn. Championed by Audi, the “Automotive Initiative 2025” aims to establish a world-leading competence network for digital factory transformation and innovation. The Audi site in Neckarsulm will assume a central role as a pilot factory and real-world laboratory for digital transformation. Relevant IT solutions and ideas will be provided by technology partners Amazon Web Services (AWS), SAP, Capgemini and the XL2 joint venture, in which Audi is a founding partner.

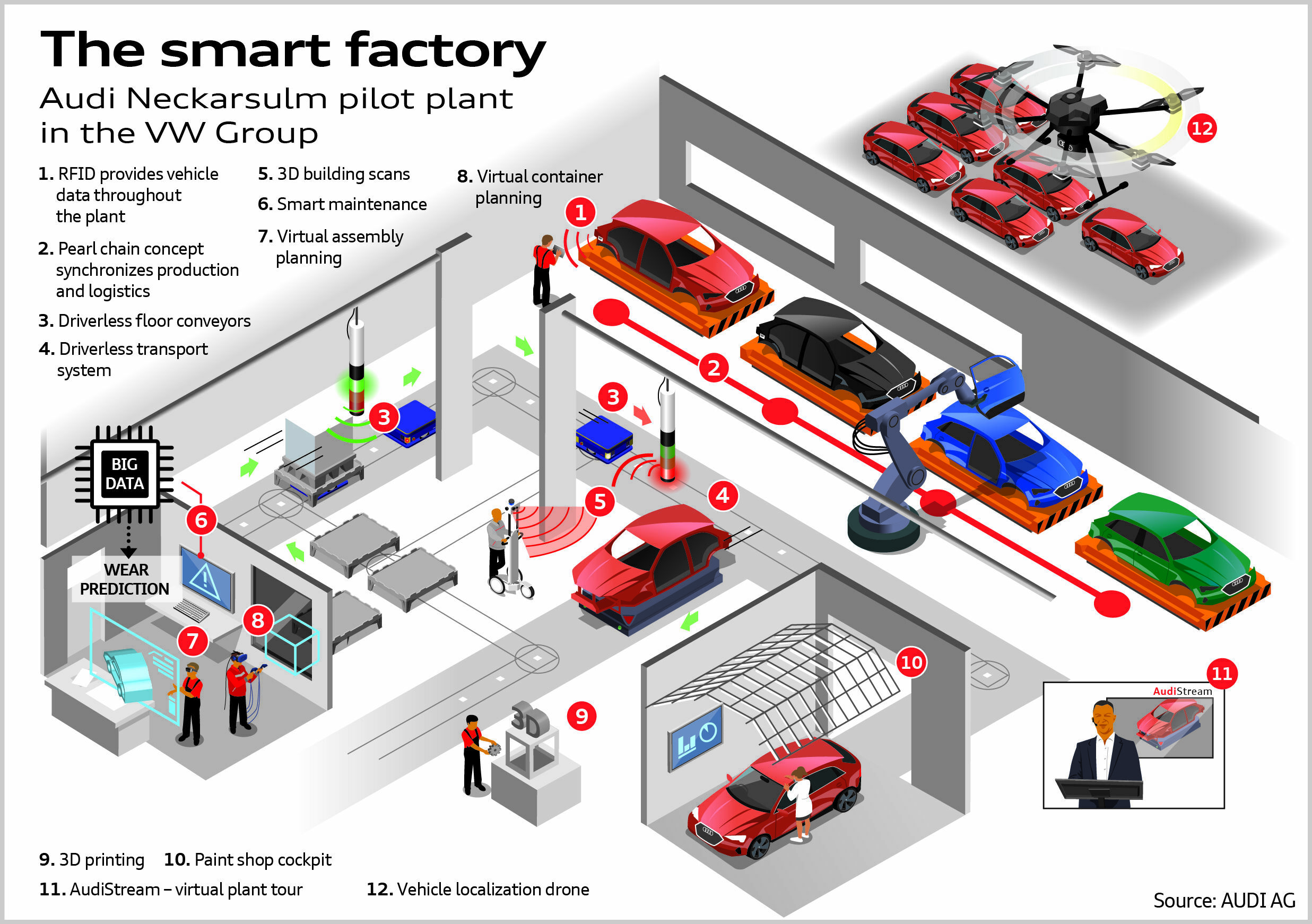

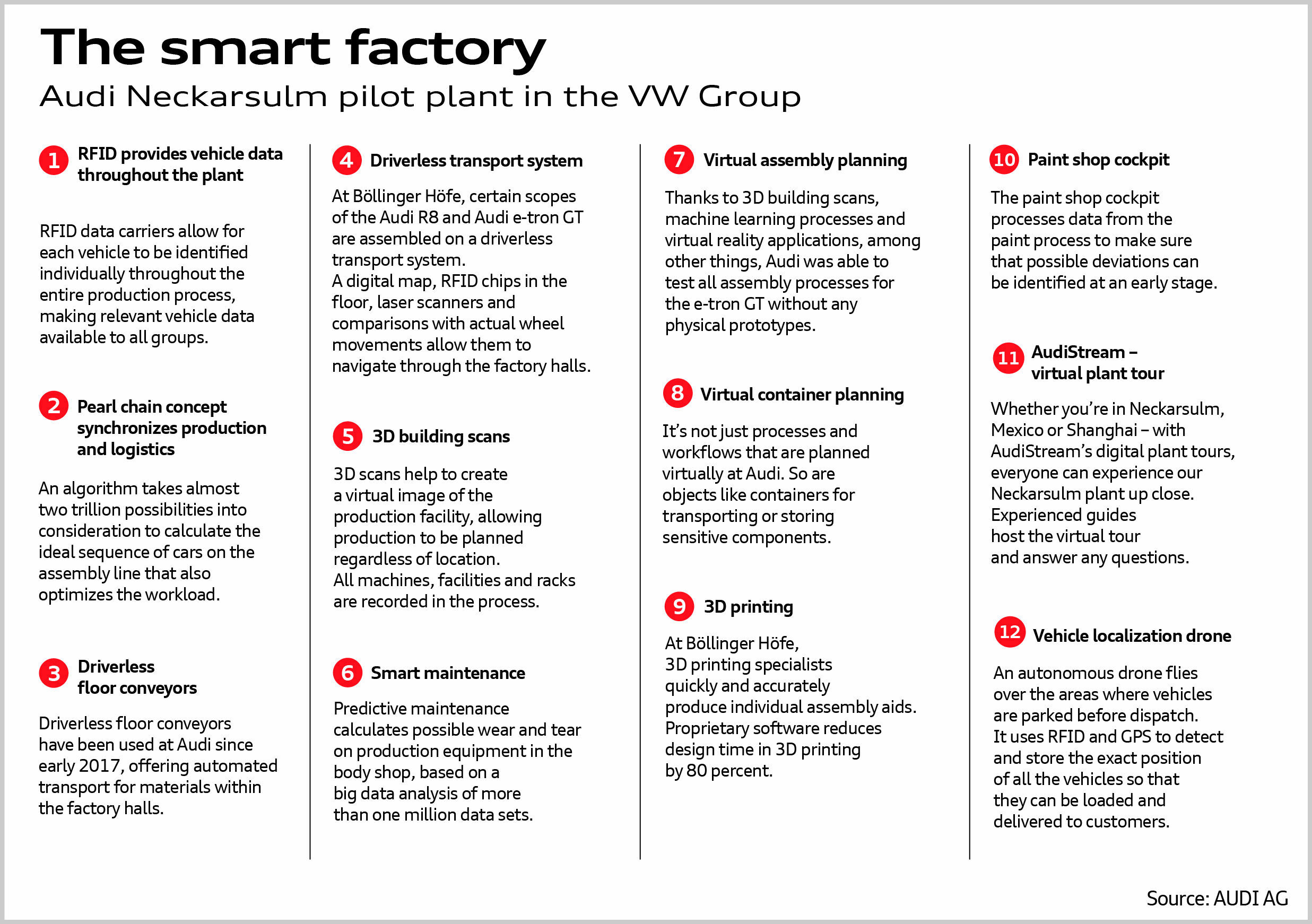

Audi already uses intelligent digital solutions at its production sites all around the world. The Four Rings are now launching the Automotive Initiative 2025 (AI25) in Heilbronn with partners from academia and the IT sector to systematically continue along this path. AI25 is striving to develop digital solutions for the factory of the future and implement them in vehicle production and logistics for series production within the next five years, with the overarching goal of making these key components of the production process even more efficient and flexible. As the pilot factory, the Audi site in Neckarsulm will become a real-world laboratory for the digital transformation and thus play a central role in the initiative. There, digital solutions for vehicle production and the supply chain will be tested and developed for use in series production. The site’s expertise in small-series and volume production will be particularly beneficial.

“We already have extensive experience in the areas of vehicle production, logistics and production IT at our Neckarsulm site. We will further enhance these capabilities in a targeted manner as part of the transformation. With our dedicated team of experts and our partners in the Automotive Initiative 2025 we develop the site into a leading factory for digital production and logistics within the Group,” said Peter Kössler, Board Member for Production and Logistics at Audi.

As part of the Bildungscampus in Heilbronn and the Heilbronn-Franken region’s Innovation and IT Network, the site will help to develop such future thinking solutions as the use of artificial intelligence or intuitive man-machine interaction. XL2, the Heilbronn-based joint venture founded last year by Audi and Capgemini, will play an important role when it comes to bringing IT innovations to the Audi plants around the world. With academic support from the Fraunhofer IAO and the Technical University of Munich, XL2 will collaborate with additional IT experts from Capgemini, SAP and AWS to develop the IT solutions required for a smart and connected factory.

Audi sites become part of Volkswagen industrial cloud

The basis for this collaboration is the Digital Production Platform (DPP), in which the data of every machine, piece of equipment and system from every plant in the Volkswagen Group are pooled. The sites thus become part of the industrial cloud, which in the future will also include the Group’s supply chain as well as additional partners. With Neckarsulm and Ingolstadt, the first two Audi sites have already been connected to the DPP; the remaining sites will follow later this year. In their collaboration, the companies will be leveraging AWS technologies in the areas of the Internet of Things (IoT), machine learning and computing services that will be developed specifically for the production environment and adapted to the requirements of the automotive industry.

Furthermore, the use of the SAP S/4HANA platform will lay the foundation for the next generation of digital production processes, on which the companies will work together on solutions for modular production and interoperable vehicle logistics. As part of this interdisciplinary collaboration between research, industry and IT, the companies will use industry-specific applications of the SAP Industry Cloud in the areas of machine learning, robotic process automation (RPA) and business process intelligence, which are holistically aligned with future needs for the automation and digitalization of the automotive industry.

Holistic view of the digital transformation

“With the Automotive Initiative 2025, we have created a pioneering, interdisciplinary network between academia, research, IT companies and automobile manufacturing. The initiative uses sound science to drive the digital transformation of automobile production within the overall context of technology, organization and particularly continuing education,” explains Professor Helmut Krcmar from TU Munich.

“AI25 is characterized by its holistic view of the digital transformation and by its clear ties to the real world. We study both strategic topics and concrete use cases that accelerate the digital transformation and generate new innovative ideas,” added Frank Loydl, Chief Information Officer (CIO) at AUDI AG.

The initiative is also expected to become an idea foundry and driver for the digital transformation of production and logistics throughout the Volkswagen Group. The knowledge gleaned will be used to help shape the future IT configuration of the automotive plants and expand this sustainably at Audi. Other goals include the definition of generally applicable standards for the transformation and the rollout of concrete use cases to all Group plants worldwide via the industrial cloud.

Additional statements on the launch of the Automotive Initiative 2025:

Dr. Bernd Bienzeisler, Head of Fraunhofer IAO site in Heilbronn:

“The Automotive Initiative 2025 offers the opportunity to combine basic research and applied research in the area of digital factory transformation to develop practice-oriented solutions.”

Felix Spitznagel, Managing Director at XL2:

“Since its founding last year, XL2 has pursued the goal of shaping the digital transformation of the automobile industry by means of innovative, agile and tailored services. AI25 now allows us to develop solutions within a high-performance regional network of research, academia and industry and deploy them across regions.”

Dr. Rainer Mehl, Managing Director Strategic Account Automotive at Capgemini:

“With the transformation to the Smart Factory and connected production, the Automotive Initiative 2025 is pursuing the same goals that Capgemini is pursuing with its approach to intelligent industry. We therefore consider this to clearly be a pioneering approach to the focused bundling of interdisciplinary competences and shaping the digital transformation for the production of the future.”

Bill Foy, Director, Worldwide Automotive at AWS:

“AWS is proud to support digital transformation across the automotive industry. Through our deep relationship, AWS and Audi are changing the way the industry applies technology advancements to the entire production process, from concept to final assembly. By bringing together AWS capabilities and the Volkswagen Group’s Digital Production Platform, Audi is creating a space where they can test the most revolutionary ideas from industry and academia, fulfill the promise of the industrial cloud, and make the smart factory of the future a reality.”

Hagen Heubach, Global Vice President Industry Business Unit Automotive, SAP SE:

“SAP is pleased to support the initiative with the industry-specific solutions of the S/4HANA platform and the SAP Industry Cloud for Automotive. Our primary focus is on driving innovations in a regional context and working in an open ecosystem.”