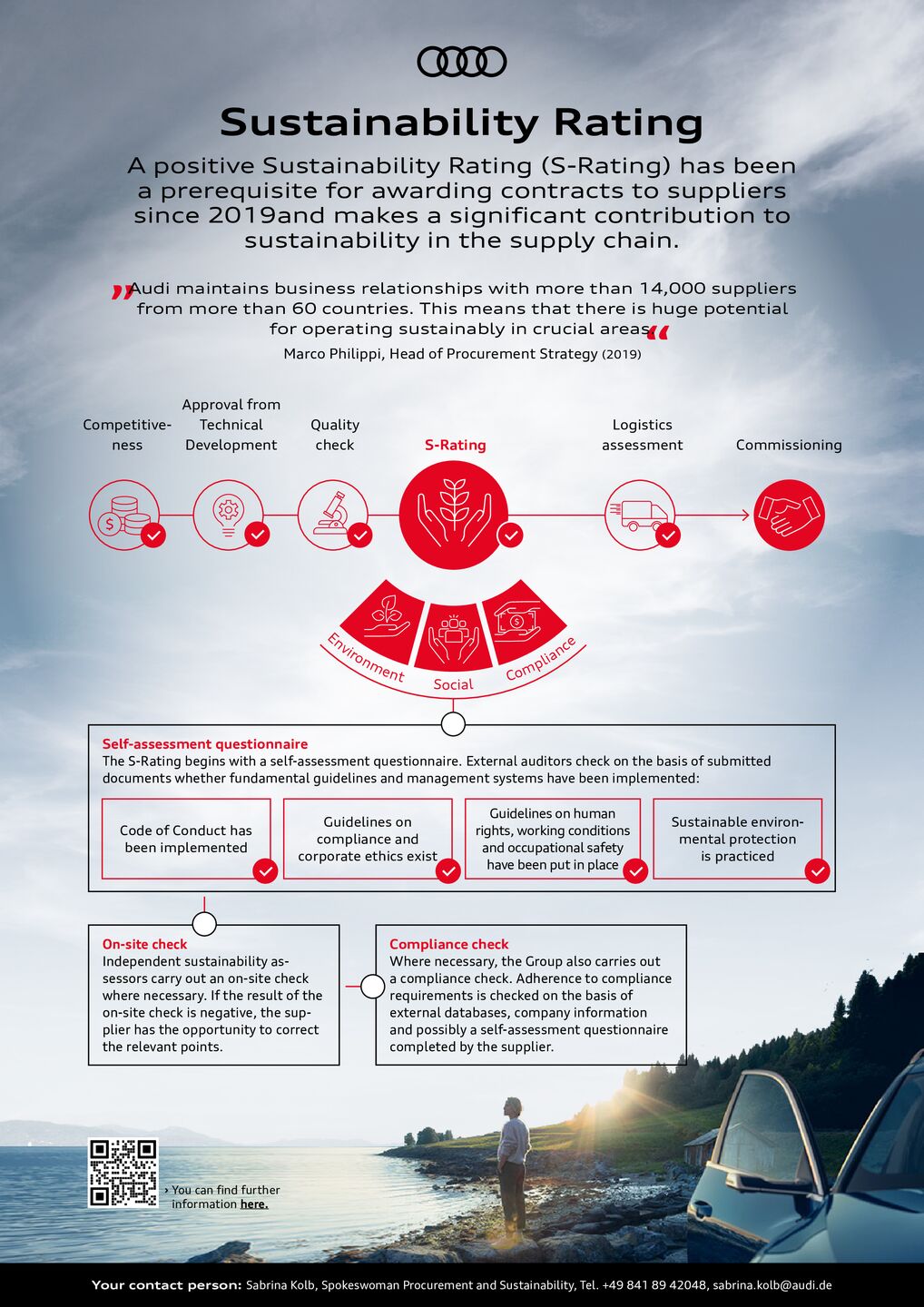

Procurement and Supply chain

The Audi supply chain is complex. In order to successfully meet the environmental, human rights, and due diligence targets, Audi requires strong partner companies along the supply chain. Sustainable action in complex manufacturing processes is only possible when all partners work together as equals in pursuing the same goal. Therefore, Audi supports its suppliers – around 12.400 from around 60 countries, in implementing sustainability in their operations. The company’s environmental, social, and compliance guidelines, defined in the Code of Conduct for Business Partners, form the basis for collaboration and are integral to its risk assessment processes. Audi closely monitors its supply chains to identify potential risks, also harnessing the power of artificial intelligence to do so.