Electric drives

Back to overviewElectric motors can vary significantly depending on the technology. In this section, we provide an overview of the different types and explain how they work.

Note: The technologies described here reflect the state of development at Audi, either as it currently stands or as it has been in the past. Not all systems mentioned are available in the current model range.

Electric all-wheel drive

Power electronics

Alongside the electric motor and transmission, power electronics (pulse inverters) are one of the main components of an electric drive system. The high-voltage battery supplies direct current, while the electric motors operate with alternating current – each motor is therefore paired with a power electronics unit that converts the current. Power electronics have a significant influence on power consumption and, consequently, on efficiency and range. That is why the Premium Platform Electric (PPE) – used in models such as the Q6 and A6 e-tron – uses silicon carbide semiconductors. This material performs highly efficiently especially in partial load ranges, allowing for minimal overall heat loss. As a result, overall efficiency improves. The use of silicon carbide also protects the battery. When the electric motors operate as generators during regenerative braking, the power electronics convert the alternating current into direct current and feed it back into the battery. Power electronics read sensor data 10,000 times per second and deliver current values to the electric motors. The result is optimal power delivery, particularly in dynamic driving conditions. Certain functions, such as vibration damping and slip control, are also integrated into the power electronics. This enables interventions to be executed without delay, which significantly improves acceleration on slippery surfaces.

Regenerative braking

Regenerative braking refers to the use of kinetic energy during deceleration. An electric drive motor in a car becomes a generator when it is being driven and the rotor spins faster than the stator’s rotating magnetic field. A distinction is made between regenerative coasting, which occurs when the driver releases the accelerator pedal, and regenerative braking, which is triggered when the brake pedal is pressed. Regenerative coasting can be automatically controlled via the predictive efficiency assistant. It proactively regulates the necessary deceleration based on factors such as the route and vehicles ahead. Alternatively, the driver can manually control the level of deceleration using the steering wheel paddles. During both coasting and braking phases, the generator converts kinetic energy into electrical energy and feeds it into the battery.

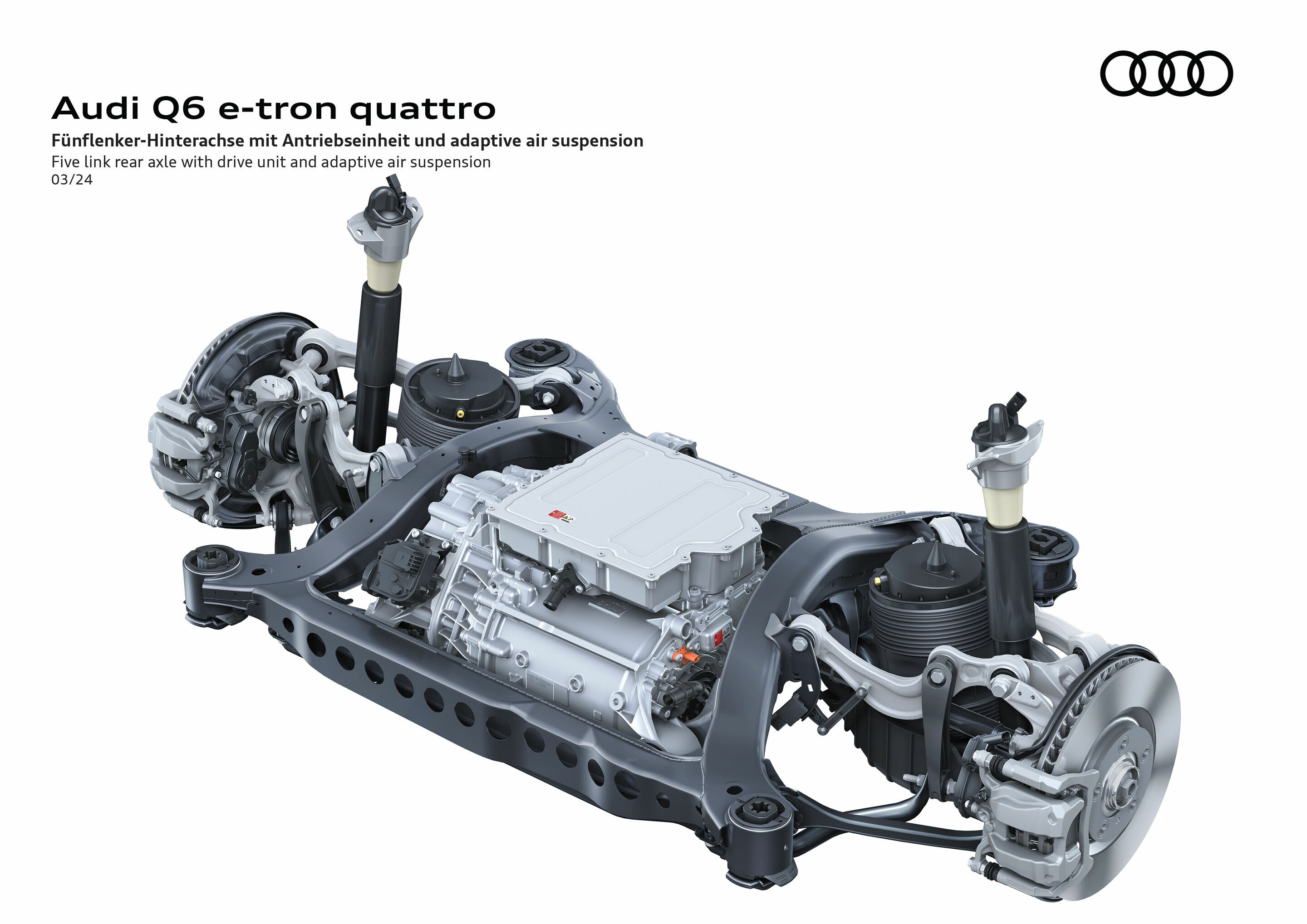

During the PPE development, particular emphasis was placed on increasing maximum efficiency and availability during so-called standstill blending in the low speed range. This means that in the Audi Q6 e-tron, around 95% of everyday braking events can be handled via regenerative braking, meaning by the electric motors. Under ideal conditions, the Q6 e-tron can recover up to 220 kW of energy. The battery temperature and state of charge play a crucial role in this. Regeneration occurs at both the front and rear axle, with smaller deceleration events handled by the rear axle for efficiency reasons. Higher regeneration levels are also possible on the rear axle. The Intelligent Brake System (iBS), known from previous e-tron models, has been significantly enhanced for the PPE platform. Individual axle blending is possible for the first time. As is typical for Audi, the Q6 e-tron also offers two-stage regenerative coasting, adjustable via the steering wheel paddles. The vehicle also supports sailing, where the electric SUV rolls freely without drag torque when the driver lifts off the accelerator. The Audi Q6 e-tron also features the “B” drive mode, which closely resembles what is commonly referred to as the “one-pedal driving” experience. This allows Audi to meet the full spectrum of customer preferences. The regenerative braking capacity of the updated e-tron GT family has increased from 290 kW to 400 kW.

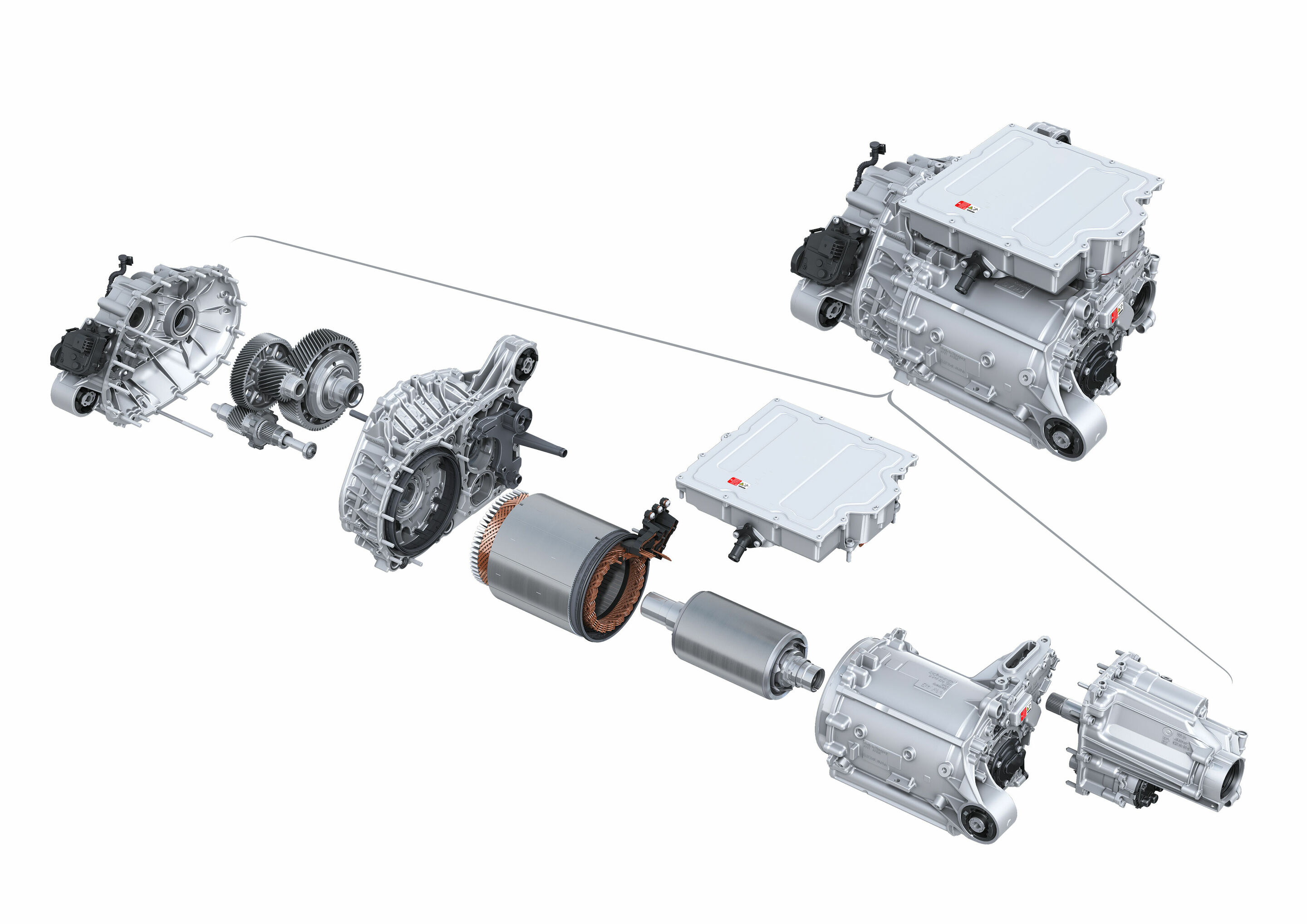

Asynchronous motor

A three-phase asynchronous motor (ASM) consists of two main components: the outer, stationary stator and the rotor located inside it. The stator is made up of a laminated core composed of thin, magnetically conductive electrical steel sheets. Within it are copper wire coils connected to the three-phase current supplied by the power electronics unit. When voltage is applied to them, a rotating magnetic field is generated – the so-called rotating field. This induces a secondary magnetic field in the rotor, which then follows the stator’s rotating field at a slightly lower speed – hence the term asynchronous. If the rotor turns at a slower speed than the rotating field, the electric motor works as a drive motor. If the rotor turns faster than the rotating field, it acts as a generator, converting kinetic energy into electrical energy. In a non-energized state, asynchronous motors do not produce any electrically induced drag losses and are therefore very efficient. In addition to their lightweight design – thanks to the aluminum rotor – they offer other advantages, such as being low-maintenance and particularly robust. The ASM on the front axle of the Q6 e-tron, which rotates without any significant drag losses, is 100 millimeters long. In the PPE platform, it is used in dynamic driving situations and is equipped with its own power electronics and a two-stage, single-speed transmission mounted parallel to the axle. Furthermore, no magnets are used in the ASM, which means that no rare earth elements are required. Its magnetic field is generated through induction.

Electronics architecture E3 1.2

With the launch of the Premium Platform Electric (PPE), Audi has introduced a completely new electronics architecture. The name E3 stands for end-to-end electronics architecture. At its core are five high-performance computers (High-Performance Computing Platforms, HCPs) that manage all vehicle functions. The overarching goal in developing E3 1.2 was to create a scalable and future-proof electronics architecture that could be used across the entire corporate Group. A key aspect of this architecture is the shift of functionality from the sensor-actuator level to the computing level, meaning an increasing decoupling of hardware and software. This approach can help manage growing system complexity in the coming years. Another focus was on establishing a high-performance and secure network between domain controllers, control units, sensors, and actuators. This ensures control over increasingly complex systems while maintaining modularity. The architecture also supports high-performance seamless backend connectivity for Car-to-X swarm data applications and computationally intensive off-board functions. Five high-performance computers form the central nervous system of the E3 1.2. All vehicle functions are distributed to the various domain computers according to domains. HCP 1 is responsible for the drive, suspension, and lateral and transverse dynamics. HCP 2 controls the driver assist systems. HCP 3 organizes all infotainment functions. HCP 4 handles comfort features such as lighting control, climate control, and seat adjustment. Finally, HCP 5 manages the central internal networking of the domain computers and establishes the connection between the vehicle and the outside digital world.

Permanently excited synchronous motor (PSM)

The permanently excited synchronous motor (PSM) is a highly effective electric motor. Permanent magnets on the rotor ensure a continuous state of magnetic excitation, meaning that the rotor is always magnetically energized. Efficiency losses – such as those caused by changing magnetic fields – are therefore lower compared to statically excited synchronous motors. One of the PSM’s major strengths is its efficiency, with a conversion rate exceeding 90% in most driving conditions. A high-tech manufacturing solution is used – hairpin winding. The stator coils are made of rectangular copper wires, which resemble hairpins when bent. This makes it possible to pack the wires more densely, increasing the amount of copper in the stator. This in turn boosts power and torque. The new hairpin winding method, used for the first time at Audi in the Q6 e-tron, maximizes the current flow in the stator of the electric motor. It also enables a higher number of coil turns, increasing the fill factor from 45% to 60% compared to conventional windings. Thanks to rotor oil cooling, Audi was able to largely eliminate the use of heavy rare earth materials, while simultaneously increasing power density by 20%. Overall, the power loss of the electric drive system was reduced by approximately 50% compared to the Audi e-tron.

Single-speed transmission

In vehicles with internal combustion engines, torque increases with rising engine speed and decreases again after peak acceleration. In contrast, with an electric drive, the maximum torque is available immediately and remains largely constant thereafter. The use of a multi-speed transmission for optimal power delivery to the wheels is therefore generally not necessary in electric vehicles. The single-speed transmission used in the MEB platform has two modes: forward and reverse. To switch driving direction, the electric motor’s rotation is simply reversed. The power from the electric motor is transmitted to the wheels with a gear ratio of approximately 10:1. Due to space constraints, the single-wheel transmission does not use one large gear but two smaller gears instead. Because electric drives are very quiet, even the smallest operational noises (e.g. windshield wipers) become noticeable. The components of the single-speed transmission must therefore be designed and assembled to minimize noise emissions. An electric oil pump integrated into the transmission of PPE models contributes significantly to increased efficiency.

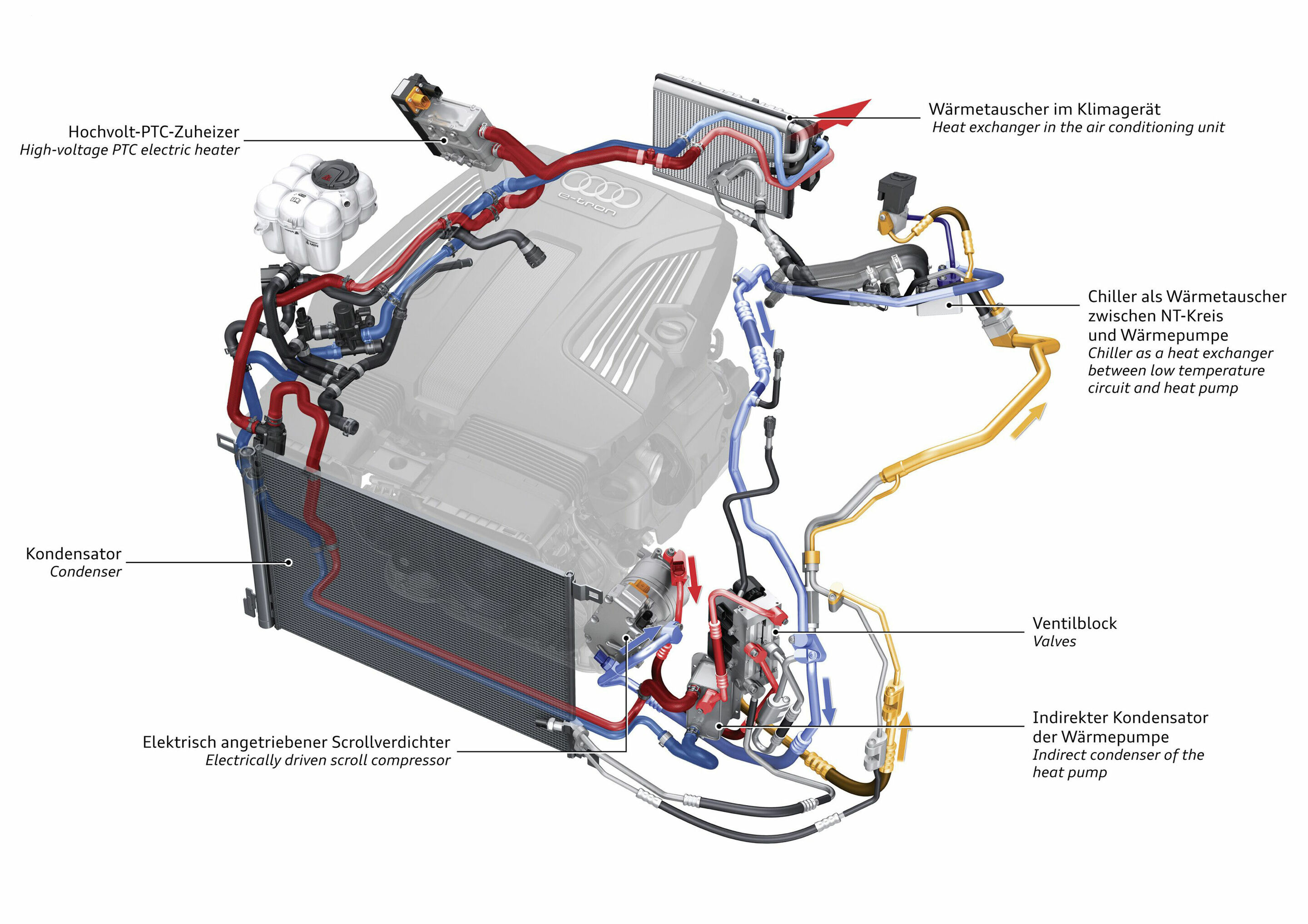

Heat pump

A standard integrated heat pump utilizes the waste heat generated by the electric drive components to heat the vehicle interior. This enables efficient heating performance, especially at low outside temperatures. The energy saved in this process can be redirected to power the vehicle.

Audi was the first car manufacturer to introduce a heat pump with an electrically driven compressor as standard in a plug-in hybrid model back in 2015. In order to bring the interior to the desired temperature, a refrigerant circuit collects the waste heat emitted by the high-voltage components of the electric drivetrain. The heat pump operates with exceptional efficiency: with just one kilowatt of electrical input, it can generate up to three kilowatts of thermal output. Compared to a purely electric heating system, the heat pump extends the electric driving range, which is particularly beneficial in winter. In the Q6 e-tron, Audi uses both an air-source heat pump and a glycol-based heat pump for the first time. The water circuit thus no longer needs to be heated.

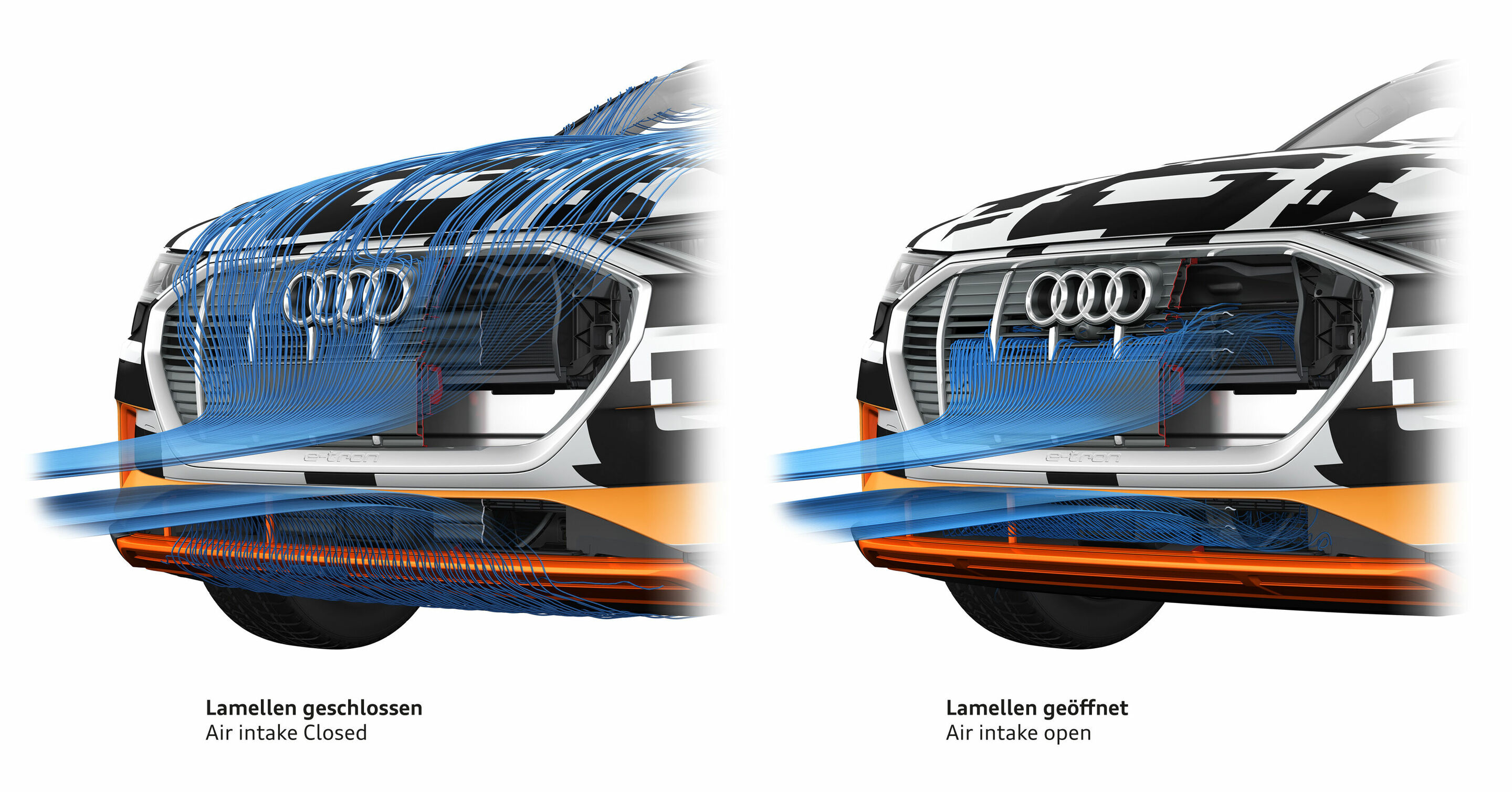

Controllable cool-air intake

In front of the radiator and condenser unit, which receives airflow through the lower central intake, there is a frame fitted with an electrically operated louver system. This louver is opened as needed, for example during charging, when the components require cooling air. When optimally managed, this system can provide a range benefit of several kilometers, depending on the vehicle model. In most driving situations, however, the louver remains closed to reduce aerodynamic drag caused by airflow through the narrow cooling channels.

MHEV plus

The MHEV plus mild hybrid system is based on the interaction between the powertrain generator (PTG) and the belt alternator starter (BAS) as well as a 48-volt lithium iron phosphate battery. This combination supports the combustion engine, reduces carbon emissions, and increases performance and agility at the same time. The PTG, which can be fully coupled or decoupled, enables partially electric driving, which reduces consumption and provides an even more comfortable driving experience. The MHEV plus system can be integrated into various models with front and quattro drivetrains based on the Premium Platform Combustion (PPC). MHEV plus utilizes the PTG up to a maximum speed of 140 km/h for maximum efficiency.

The PTG, which is installed in a compact unit with integrated power electronics directly on the output shaft of the transmission, can contribute up to 18 kW (24 PS) of electrical power to the drive. The module enables a maximum torque of 230 Nm at the transmission output, which is already available as drive torque when the vehicle is started. The PTG’s compact transmission operates with a ratio of 3.6:1. The PTG weighs around 21 kilograms and enables a maximum of 5,550 revolutions per minute on the output shaft. Thanks to its positioning directly behind the gearbox, the 18 kW of drive power or up to 25 kW of power from regenerative braking supplied by the PTG is available directly at the axle output without any further losses. The operating temperature range extends from -40 to +75 degrees Celsius. A water jacket surrounds the electric motor and also cools the compact and highly integrated power electronics in the common coolant circuit, which is mounted directly on the electric motor to save space. The high-performance power modules are arranged around the heat sink within the power electronics. The intermediate circuit capacitors are surrounded by the heat sink in a space-saving and thermally optimal way.

As part of the MHEV plus technology, the BAS is tasked with starting the engine and delivering electrical energy to the battery. The lithium-ion battery made with lithium iron phosphate (LFP) has a storage capacity of 37 ampere-hours, which corresponds to just under 1.7 kWh (gross). Its maximum discharge power is 24 kW. Due to the requirements for availability, power, and torque, the battery is integrated into a low-temperature water-cooling circuit that ensures optimal conditions in the range of 25 to 60 degrees Celsius. This is the first time that Audi is using an LFP battery for its mild hybrid systems. Control software evaluates the operating state of the vehicle for the optimal interaction between the combustion engine, PTG, and BAS.