Battery technology

Back to overviewNot all batteries are the same. Here, we explain the different technologies that exist - and how they work.

Note: The technologies described here reflect the state of development at Audi, either as it currently stands or as it has been in the past. Not all systems mentioned are available in the current model range.

Battery Management Controller (BMCe)

A new central control unit developed for the Premium Platform Electric (PPE), the Battery Management Controller (BMCe), is responsible for regulating the flow of electricity for fast, battery-friendly charging. The BMCe is fully integrated into the high-voltage battery of PPE models. It controls key battery parameters such as charge status, power output and thermal management. As part of continuous monitoring, the Cell Module Controllers (CMC) send data such as the current module temperature or cell voltage to the BMCe, which sends this data – for example, regarding the state of charge (SoC) – to the high-performance HCP4 computer (part of the new E3 1.2 electronics architecture). From this computer, the data is sent to the predictive thermal management system, which regulates the cooling or heating circuit as required for optimum battery performance.

Thermal management

By balancing the heat flows between the powertrain, high-voltage battery and interior, thermal management ensures that the battery in fully electric models quickly reaches and remains in its optimum operating range – from cold starts in winter to fast motorway driving on hot summer days. This not only allows the vehicle to accelerate several times without any loss of performance. It is also a prerequisite for high and repeatable performance when fast charging. At the same time, thermal management contributes to the longevity of the battery. The control software for the charging process counteracts the progressive ageing process of the battery. The software adjusts the currents and voltages according to age and remaining capacity so that the battery is not overloaded during charging.

The heat pump system, which converts energy from the powertrain or the ambient air, has proven itself in this context. It compensates for the reduced waste heat from the increasingly efficient powertrain. This provides two independent systems for heating the interior and the high-voltage battery.

Intelligent thermal management contributes significantly to the high charging performance and long service life of the HV battery in the Premium Platform Electric (PPE). The most important component is predictive thermal management, which uses data from the navigation system, the route, the departure timer and customer usage behavior to calculate cooling or heating requirements in advance and provide them efficiently and at the right time. If a fast-charging station included in the route planning is approached for charging, the predictive thermal management system prepares the DC charging process and cools or heats the battery to enable faster charging and thus shorten the charging time. If a steep incline is ahead, the thermal management system adjusts the HV battery by cooling it down to prevent higher thermal loads.

If the driver does not provide any information from which predictive data can be derived, a baseline algorithm regulates the thermal management of the HV battery. This also collects a lot of information and reacts to the driving situation. If drivers have selected efficiency mode in the drive-select menu, for example, battery conditioning is activated later and the real-world range can increase depending on driving behavior. In dynamic mode, the aim is to achieve optimum performance. However, if the current traffic situation does not allow dynamic driving, the thermal management system responds and minimizes the energy used for battery conditioning.

A new feature in PPE thermal management is post-conditioning and continuous conditioning. This function monitors the battery temperature throughout its entire service life to keep the battery in the optimum temperature range even when the vehicle is stationary – for example, in hot outside temperatures. This measure also helps to extend the battery's service life.

High temperature homogeneity within the battery increases performance, which is why the coolant is routed below the modules using the U-flow design. The battery cooling plate is also part of the battery frame, eliminating the need for an additional floor panel in the HV compartment of the battery housing and optimizing the thermal connection to the modules via a thermal paste.

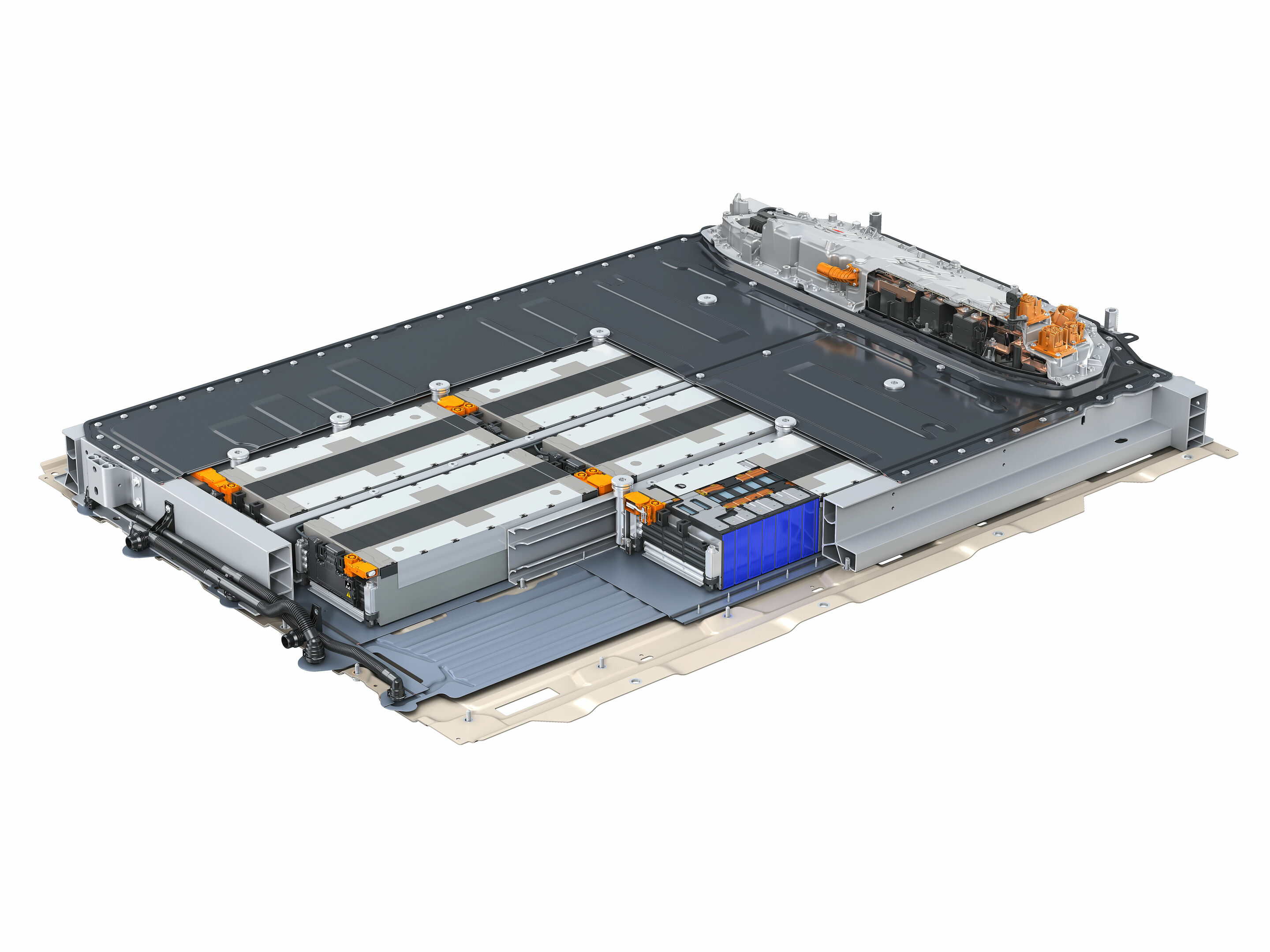

High-voltage battery system

Compared with the battery systems previously used, the battery for the Premium Platform Electric (PPE) consists of only twelve modules with a total of 180 prismatic cells. By way of comparison, the HV battery in the Audi Q8 e-tron comprises 36 modules and 432 cells. The significant increase in cell size correlates almost perfectly with the system voltage of 800 volts, thus achieving the best possible compromise between range and charging performance. The ratio of nickel, cobalt and manganese in the cells for the PPE is approximately 8:1:1. The cobalt content has been reduced and the nickel content, which is particularly relevant for energy density, has been increased.

Reducing the number of modules for the PPE batteries brings a number of advantages. The battery, which can be used in a modular fashion for high- and flat-floor models, requires less installation space, is lighter and can be better integrated into the crash structure and cooling system of the vehicle. It also requires fewer cables and high-voltage connectors. The number of screw connections has been significantly reduced. In addition, the electrical connections between the modules are shorter, which significantly reduces power loss and weight. A cooling plate integrated into the battery housing ensures homogeneous heat transfer and thus almost optimal conditioning of the battery. The protective side skirts made of hot-formed steel are not attached to the battery but are instead secured to the body for extra stability. Another new feature is the underbody protection made of a fiber-composite material. This design also reduces weight and improves the thermal insulation of the battery from the environment. This allows the battery for the PPE to be cooled or heated more efficiently.

If a charging station with 400-volt technology is used, the PPE enables bank charging for the first time. This automatically divides the 800-volt battery into two batteries with the same voltage, which can be charged in parallel with up to 135 kW. Depending on the state of charge, both battery halves are first equalized and then charged together.

The high-voltage batteries of the MEB platform operate at a nominal voltage of 352 volts. Controllers located in the longitudinal support of the housing monitor the modules and cells for voltage and temperature. In cooperation with the central battery management controller, they compensate for small deviations in the capacity of the individual cells. The main control unit and the connection box with its fuses are mounted in the rear of the battery system. In the event of a serious accident, the power supply to all other high-voltage components is immediately interrupted.

The thermal management of the compact electric SUVs based on the MEB consists of two coolant circuits. One of these regulates the temperature of the electric motors, the power electronics, the onboard charger and the DC/DC transformer, which connects the 12-volt electrical system to the high-voltage system. This medium-temperature circuit is connected to a low-temperature circuit that supplies the traction battery exclusively. The coolant – a water-glycol mixture – flows through the flat channels in the floor panel, cooling the cell compartments from below. A heat-conducting paste establishes the thermal connection. At low outside temperatures, a high-voltage heater ensures that the coolant warms up quickly.