Search

All search results for " Ingolstadt"

(1811)

incampus opens in Ingolstadt: Ground for new ideas

incampus opens in Ingolstadt: Ground for new ideas

The official opening of the incampus technology park was attended by Minister-President of Bavaria Markus Söder and Mayor of Ingolstadt Christian Scharpf. On the former refinery site, Audi and its partners will work on the future of mobility. Audi already has a new Vehicle Safety Center and an IT Center at the site, and the Volkswagen Group’s software company CARIAD also has its biggest tech hub there.

IN-Campus GmbH is a joint venture between the City of Ingolstadt, through its holding company IFG AöR, and AUDI AG. It created a technology park that’s already being used by the VW software company CARIAD and the Technische Hochschule Ingolstadt, among other companies. With the official opening of the incampus, Audi is also celebrating the inauguration of its new Vehicle Safety Center on the site. The company’s new IT Center on the incampus started operations back in 2022. Space for more companies and institutions will be opened up in subsequent construction phases. At the opening ceremony, the technology park was officially inaugurated by Minister-President of Bavaria Markus Söder, Mayor of Ingolstadt Christian Scharpf, Audi CEO Gernot Döllner and CARIAD CEO Peter Bosch. "With the opening of the incampus in Ingolstadt, a modern innovation and technology center for mobility has been created at a former refinery. Science, research, innovation, and ecology come together here," said Minister-President Söder. “The constant change in our city can be seen at the incampus. Innovation and the future are being created at the former refinery site – and with them, new innovative jobs. I’m also pleased that we were able to restore substantial areas to nature after the remediation. This successful cooperation between business and municipality in the remediation and development of the site is exemplary. The incampus is a major win for Ingolstadt,” Mayor Scharpf said. For Audi, too, this collaboration with the city may serve as a role model for other regions.

Live from Ingolstadt:

Annual Press Conference of AUDI AG

Live from Ingolstadt:

Annual Press Conference of AUDI AG

(CET) Audi Forum Ingolstadt A livestream is available at http://www.audimedia.tv/. This link also offers the possibility to integrate the livestream of the event into websites. The Annual Press Conference can be followed also on the livestream on the new Facebook page of Audi Communication (www.facebook.com/AudiAG) at http://bit.ly/AudiJPK15 and can be integrated using embedded code. TV stations can record the Press Conference via downlink (see satellite coordinates below). TV footage is available at www.audi-mediaservices.com. You will also find additional information there as well as images and the web video for the Audi Annual Press Conference. If you have any questions, please contact Frank Erik Horlbeck of TV Communications (frank-erik.horlbeck@audi.de, Tel.: +49 841 89 37568). He will also provide local technical support with TV, web TV or radio productions.

Audi Ingolstadt: net carbon neutral production since January 2024

Audi Ingolstadt: net carbon neutral production since January 2024

Production of the upcoming fully electric Audi Q6 e-tron series, as well as all other vehicles built at the site, will be net carbon-neutral Audi Board Member for Production and Logistics Gerd Walker: “By transitioning the Ingolstadt site to renewable energies, we are taking a major step toward our goal of net carbon-neutral vehicle production” As part of the environmental program Mission:Zero, all Audi sites will be net carbon-neutral by 2025

The Audi plant in Ingolstadt began net carbon-neutral production on January 1, 2024. After Brussels (Belgium, 2018) and Győr (Hungary, 2020), it is the third Audi plant to operate with net zero emissions. In addition are the Audi R8 and e-tron GT quattro models, which have been built at Böllinger Höfe with net zero emissions since 2020. As part of its Mission:Zero environmental program, Audi has set itself the goal of achieving net carbon neutrality at all its sites worldwide by 2025. By then, the final steps will have been taken in Neckarsulm and San José Chiapa (Mexico).

Audi Board Member for Production and Logistics Gerd Walker emphasizes: “Protecting the environment as best as possible is firmly anchored in Audi’s corporate strategy. By transitioning the Ingolstadt site to renewable energies, we are taking a major step toward our goal of net carbon-neutral1 vehicle production.” To achieve its ambitious goal, the brand with the four rings is implementing a four-pillar concept.

1. Increasing energy efficiency In the first pillar, Audi is improving energy efficiency at its sites, which will already avoid large amounts of carbon emissions.

Audi in Ingolstadt

Audi in Ingolstadt

Audi in Ingolstadt

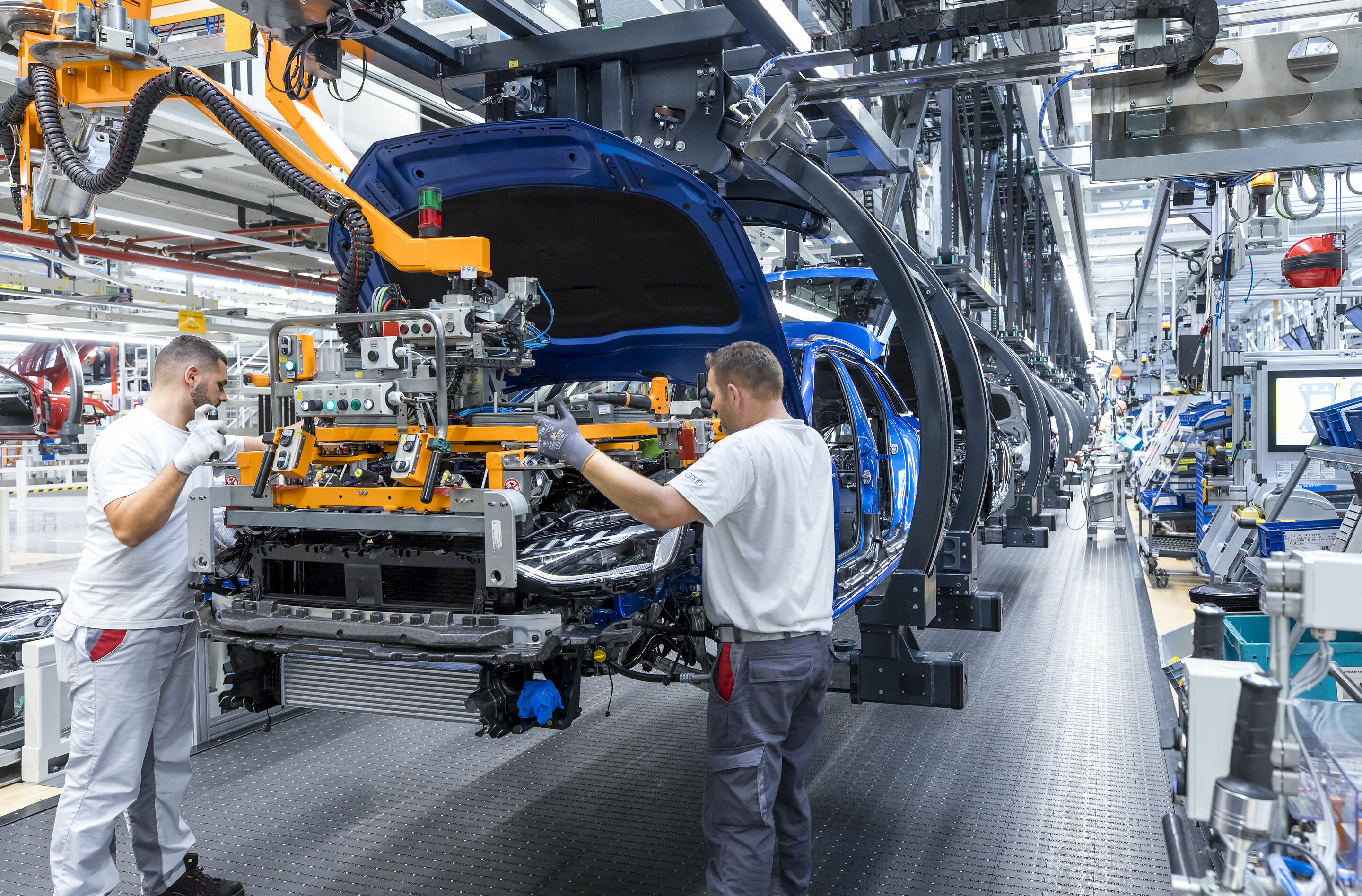

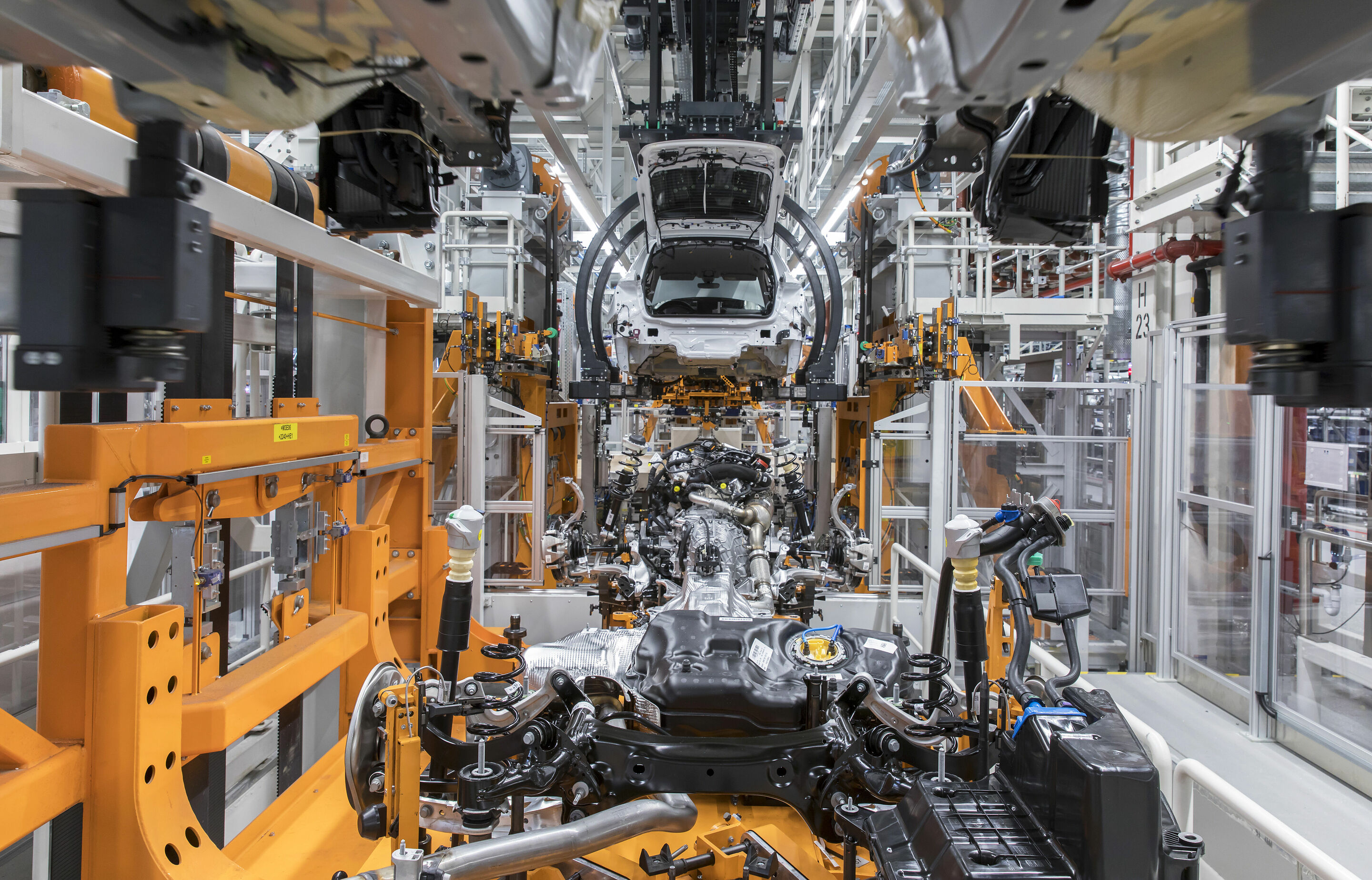

Audi has built cars at the Ingolstadt site for 75 years. This is where AUDI AG has its headquarters; around 40,000 employees (as of December 31, 2024) work in Ingolstadt to achieve “Vorsprung durch Technik”. From the initial idea to the finished automobile, the entire production process for the Audi Q2, Audi A3, Audi A6 e-tron, and Audi Q6 e-tron takes place at the Ingolstadt plant. The Audi Ingolstadt location continues to develop into a networked digital factory for the electrified future. Modern production systems and high-tech solutions enable highly efficient, sustainable manufacturing. With the Audi A6 e-tron and Audi Q6 e-tron, two fully electric models are rolling off the line in Ingolstadt. By making the assembly lines more flexible across the board and thanks to a battery assembly facility located nearby, the location is well prepared for the gradual shift to electric mobility and production of additional fully electric models. Current model series at location: Audi Q2, Audi A3, Audi A6 e-tron, Audi Q6 e-tron

Audi Forum Ingolstadt

At its main business site in Ingolstadt, AUDI AG offers visitors a comprehensive brand experience. The Audi Forum Ingolstadt is open to everyone with an interest in the brand and is a popular point of attraction and a tourist highlight for people from the region and around the world.

Arno-Michael Drotleff

Production Sites Audi Group

Audi Forum Ingolstadt

Audi Forum Ingolstadt

At its main business site in Ingolstadt, AUDI AG offers visitors a comprehensive brand experience. The Audi Forum Ingolstadt is open to everyone with an interest in the brand and is a popular point of attraction and a tourist highlight for people from the region and around the world.

At the car delivery in the Customer Center, customers and their companions take delivery of their new Audi cars. In the Audi museum mobile, the focus is on the history of the brand. Over 100 automobiles, bikes and multimedia presentations illustrate the long tradition of Audi in a captivating way. Various discovery tours through the factory offer insights into state-of-the-art automotive production at the Ingolstadt business site. The Audi independent cinema offers daily showings from its selection of movies which have won numerous awards. The Audi Forum Ingolstadt is a popular meeting point thanks to the wide variety of events held there, such as the successful concert series “Jazz im Audi Forum Ingolstadt”. In the Audi shop and in the museum shop, interested visitors will find high-quality items. The gastronomical experience comprises the live cooking market restaurant, the AVUS fine dining restaurant and the Bar & Lounge. Companies from across Germany value the conference area with conference rooms of various capacities.

AudiStream - experience the world of Audi

With AudiStream, interested parties can get an online glimpse into the world of Audi. In a variety of interactive streams, tour guides lead them through the production sites in Ingolstadt and Neckarsulm, for example.

Pictures

Audi Ingolstadt: Siegfried Schmidtner to become new plant manager in December

Audi Ingolstadt: Siegfried Schmidtner to become new plant manager in December

Siegfried Schmidtner will take over management at Audi headquarters on December 1, 2022 After more than 30 years at Audi, current plant manager Achim Heinfling will retire at the end of the year Board Member for Production and Logistics Gerd Walker: “Achim Heinfling successfully set the course for transformation in Ingolstadt. Siegfried Schmidtner will lead the site into the electric future.”

A native of Ingolstadt will take over management of Audi’s parent plant: Siegfried Schmidtner, currently responsible for Product Engineering, will head the Ingolstadt site from December 1, 2022. He will succeed Achim Heinfling, who is retiring after more than 30 years at Audi.

Schmidtner is currently head of Product Engineering in the Production and Technical Development divisions. In this capacity, he is responsible, among other things, for production-ready product design and the building of prototypes and preproduction vehicles. “With his comprehensive expertise in process chains and production ramp-ups, Siegfried Schmidtner has played a key role in the successful launch of various model series,” says Audi Board Member for Production and Logistics Gerd Walker. “As plant manager, he will lead the site into the new era of all-electric models.” Ingolstadt is to become the blueprint for the transformation of Audi’s international production network. After studying mechanical engineering at the Technical University of Munich, Schmidtner earned his doctorate in the field of product design and process chain planning. In 1998, he joined Audi in Production Planning. He then held various management positions, headed production at the Ingolstadt site, and oversaw the initial ramp-ups for the Audi A3 and Q2. Following project management for the Premium Platform Electric and the Audi A4, A5, and Q5 models, Schmidtner was in charge of key functions in the Audi Production division, with a focus on production strategy, digitalization, and transformation.

Brand with the four rings supports the DEL team, the ice hockey club’s junior program, and the women’s team Company remains committed to sports in the region surrounding its Ingolstadt headquarters Cooperation built on trust and characterized by joint activities

The partnership between AUDI AG and ERC Ingolstadt is going into overtime: The premium car manufacturer and the Ingolstadt ice hockey club have once again renewed their cooperation for the long term. Audi’s commitment to support the club goes beyond the German Ice Hockey League (DEL) professional team itself, extending to the club’s junior program and the ERC women’s team. In this way, Audi is again renewing its commitment to the region by promoting a diverse program of sports and culture.

“We are very pleased that the partnership with one of Ingolstadt’s sports flagships will continue,” says Audi Member of the Board of Management for Human Resources Xavier Ros. “Many Audi employees are themselves active members of ERC or passionate fans of the club.” On that note, the pro team is virtually spoiling fans at the moment: This season, the team breezed their way to the DEL playoffs as second in the table. Head coach Mark French’s team is now in the German championship quarterfinals. ERC last won the DEL title in 2014 – with Audi as its partner back then as well. Gerd Walker, Member of the Board of Management for Production and Logistics, emphasizes: “Renewing our contract also sends a strong signal to the Ingolstadt location and the region.” Audi also supports the club’s junior program, which was once again awarded the top rating of five stars by the German Ice Hockey Federation (DEB) in 2022 and secures the future of the club’s success. For example, the U20 team in the German Junior League (DNL) entered the German championship playoffs after the main round heading the group. The U17 team will again play in Germany’s top division in the coming season.

Audi creates 500 new electric mobility jobs at its Ingolstadt location

Audi creates 500 new electric mobility jobs at its Ingolstadt location

As production of the fully electric Q6 e-tron series begins, Audi is advertising new production jobs in Ingolstadt Xavier Ros: “The path to e-mobility provides a high volume of employment and new jobs” In addition to creating jobs specifically for e-mobility, Audi continues to drive employee qualification in fields of the future

Audi is kicking off the largest model initiative in its history with the start of production for the new Audi Q6 e-tron series based on the Premium Platform Electric (PPE). The first fully electric model series to be made in Ingolstadt demonstrates how Audi is preparing and qualifying its employees for the new era of electric mobility.

“With 500 additional jobs for the production of our new fully electric Q6 e-tron, we are showing that our transition to electric mobility is a driver of job creation. By guaranteeing a high volume of employment and new jobs, electrification will increase job security at our German locations,” says Xavier Ros, Chief Human Resources Officer at Audi. That is why, Audi is also considering temporary employees who already work in Ingolstadt in the application process. In addition to creating jobs specifically for e-mobility, the transformation of the workforce is an essential part of Audi’s transition to electric mobility. “Our employees who continue to gain qualifications and reinvent themselves professionally is what makes the transition to electric mobility possible,” adds Ros. To this end, Audi provides numerous training and development opportunities for employees. The focus is on developing and qualifying existing employees for new tasks. Over the past 18 months, Audi has qualified around 8,300 employees from Production, Technical Development, and Sales in Ingolstadt ahead of the launch of the Q6 e-tron series. In 2022 alone, AUDI AG invested around 150 million euros into the training and development of its employees.