Combustion engines and hybrid drives

Back to overviewNot all automatic transmissions are the same, and not all drivetrains are the same. In this section, we explain the different technologies and how they operate.

Note: The technologies described here reflect the state of development at Audi, either as it currently stands or as it has been in the past. Not all systems mentioned are available in the current model range.

Contents

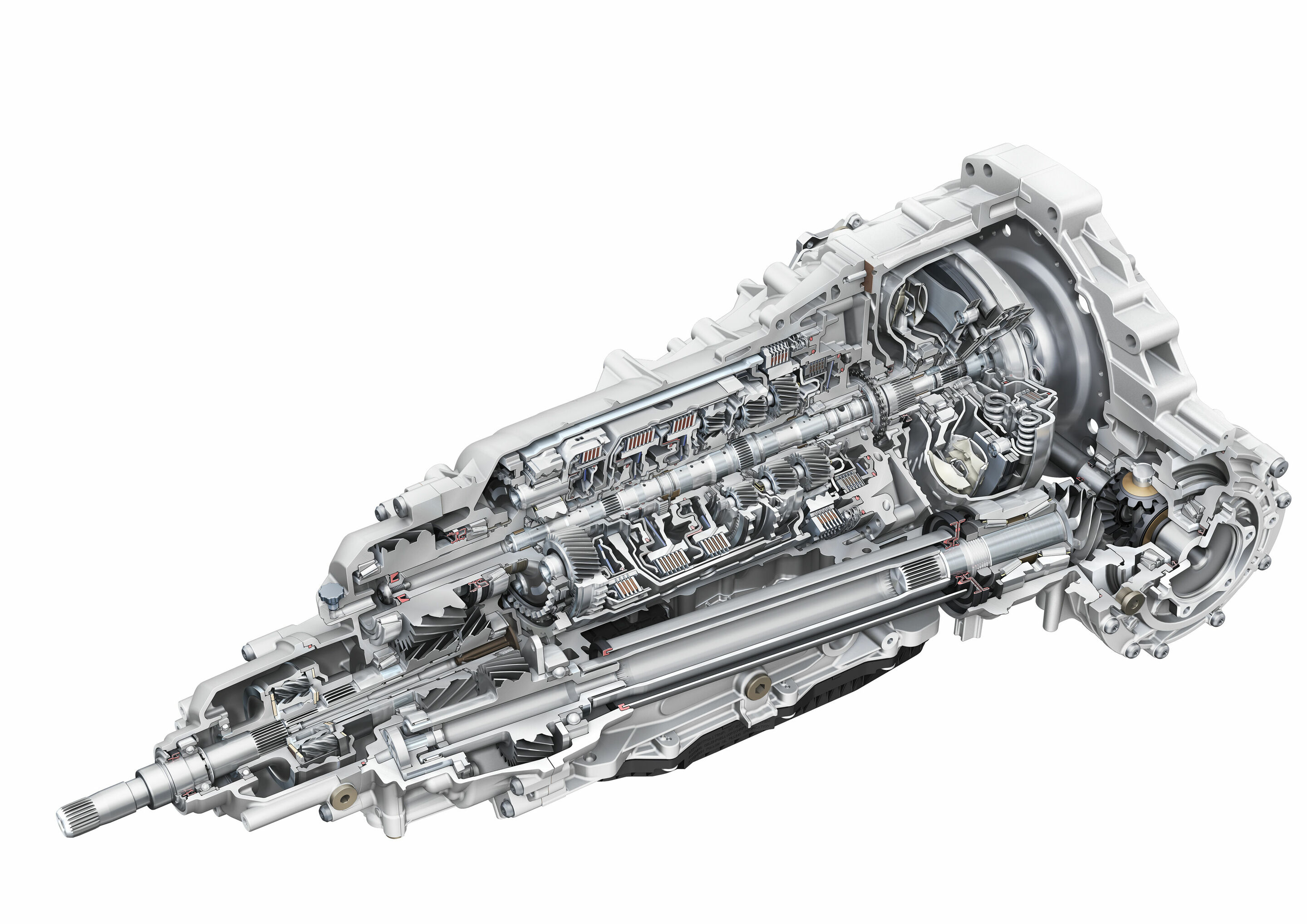

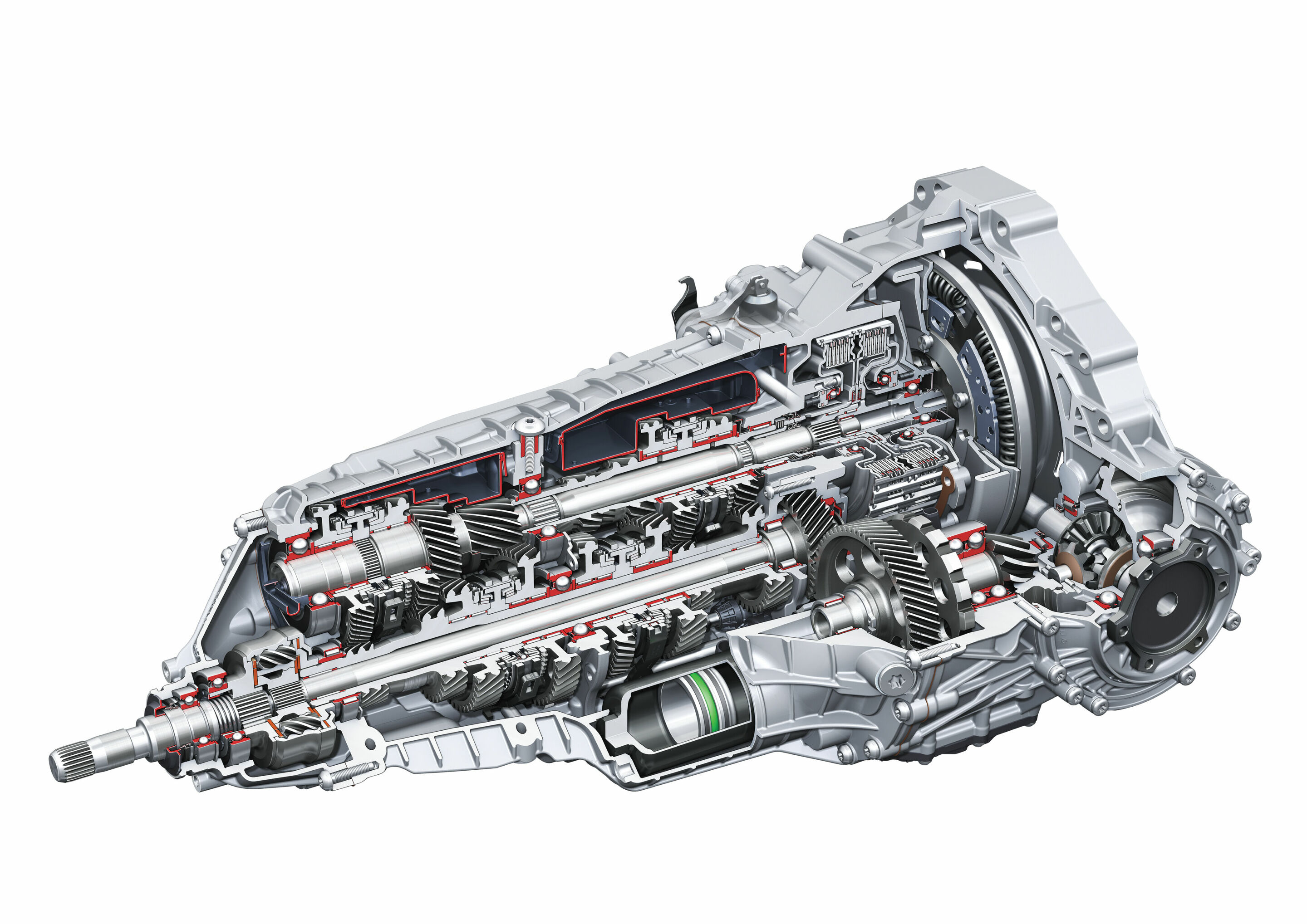

8-speed tiptronic

The 8-speed tiptronic is a classic torque converter automatic transmission, whose greatest strength lies in its high degree of shifting and starting comfort. Gear changes are smooth, spontaneous, fast, and highly flexible. Audi uses it in many models with longitudinally mounted engines. Thanks to the eight gears, the rpm jumps between gears remain small, and the engine always runs close to its ideal operating point. A speed-adaptive torsional damper compensates for unwanted engine vibrations and enables efficient driving at particularly low speeds.

The torque converter lock-up clutch with integrated damper also contributes to the high efficiency. In normal driving, the clutch is closed and connects the transmission directly to the engine. In some driving situations, it operates with controlled slip – in conjunction with the damper, this allows very low engine speeds without vibrations occurring. When the car is stationary, an internal clutch disconnects the transmission from the engine even if “D” is still engaged – this avoids losses from oil circulation in the converter. As soon as the driver releases the brake, the clutch closes again, and the damping effect of the torque converter ensures a smooth start.

The dynamic shift program (DSP) controls the 8-speed tiptronic. It uses a fast processor. In operating mode D, the DSP automatically determines the optimal shift point. It prefers high gears and low engine speeds for efficient driving. In a second gearshift gate, tiptronic allows manual intervention in automatic operation. This makes it possible, for example, to downshift on winding mountain roads to increase engine braking or to adopt a distinctly sporty driving style. In sport mode, the automatic transmission increases driving dynamics by shifting later. The selector lever communicates purely electronically, without a mechanical connection to the transmission (shift-by-wire).

The 8-speed tiptronic works together with the Audi start-stop system. For this purpose, it integrates a small, permanently filled hydraulic accumulator. When restarting after a stop, its oil volume – around 100 milliliters – is pressed by a spring-loaded piston into the shift elements required for starting. The transmission is ready to go in next to no time.

In some Audi models, the 8-speed tiptronic has an electric oil pump on board. It lubricates the transmission and enables the gear required for restarting after a coasting phase to be engaged. This allows the engine to be switched off while driving using mild hybrid technology when it is not needed for propulsion. When the car is coasting and the engine is idling, a clutch in the gearset area is opened. The transmission control detects stop-and-go situations and ensures particularly smooth starting.

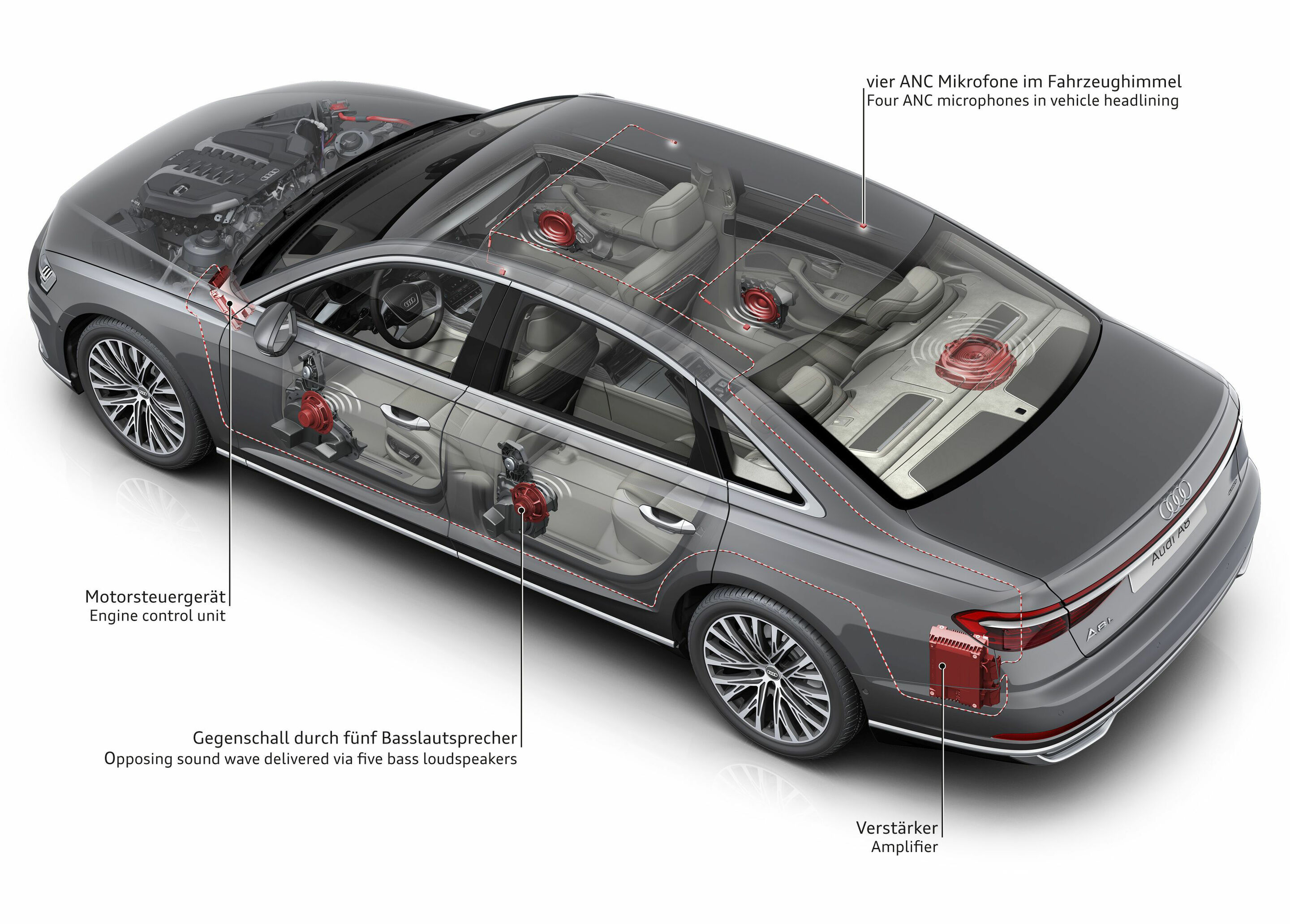

active-noise-cancellation

Active noise cancellation (ANC) reduces unwanted noise, such as certain elements of engine noise. The system uses the principle of destructive interference: when two waves of the same frequency overlap, their amplitudes cancel each other out if they are equal and their phases are offset by 180 degrees.

Small ANC microphones record the soundscape in several zones in the car’s interior and headliner. From their signals, the ANC control unit calculates a detailed spatial sound field. It also uses information about engine speed. In all zones where the system detects noise it has been calibrated to counteract, it generates precisely modulated anti-noise. The neutralizing sound waves are emitted by the bass speakers. The ANC system is always active – regardless of whether the sound system is switched on, off, loud, quiet, or muted. It works with all available sound systems.

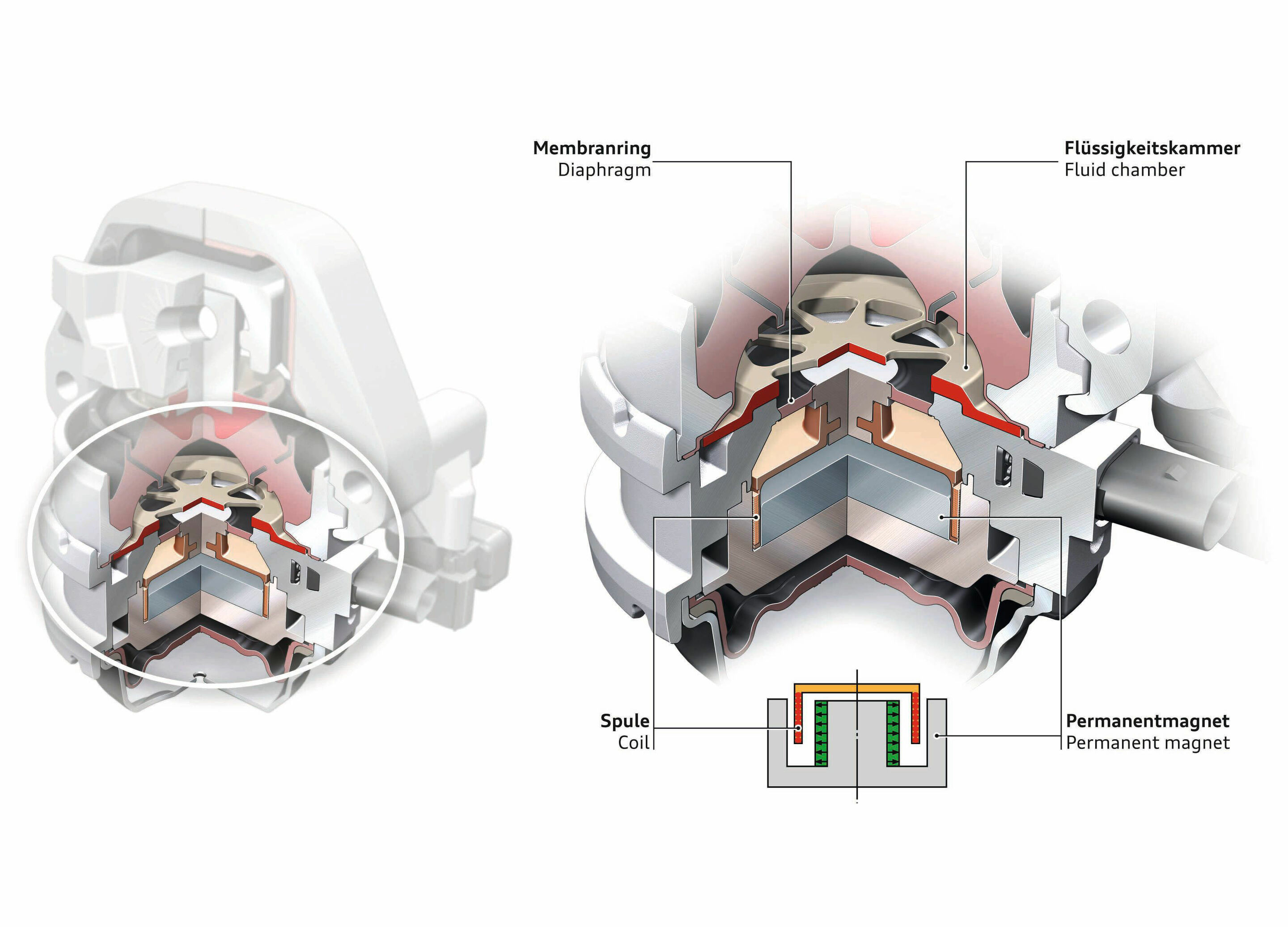

Active engine mounts

Active engine mounts reduce unwanted vibration excitation from the engine by generating compensating counter-vibrations. In order to respond to rapid changes in driving conditions, an algorithm continuously evaluates data from the acceleration sensors in the engine bay and transmits the signal for the counter-vibration to the active engine mounts.

This technology enhances the driving comfort in models with cylinder deactivation and diesel vehicles. It also helps to ensure a smooth driving experience when switching between operating modes in plug-in hybrids.

Plug-in hybrid technology

Audi has been offering plug-in hybrid models since 2014. “Plug-in hybrid” is the common term for “plug-in hybrid electric vehicle,” which is abbreviated to PHEV. In automotive engineering, the combination of a combustion engine with an electric motor has become well established in PHEV models. Typical of such parallel hybrids, the electric drive can be used locally emission-free as the sole source of propulsion, or it can support the combustion engine both in the partial-load range and with additional boost power during stronger acceleration. The electric drive also serves as a generator for regenerative braking, in which kinetic energy is converted into electrical energy and stored in a battery. In plug-in hybrids, the battery can also be charged at a charging station or power outlet.

The drive concept of a plug-in hybrid is designed so that many short distances can be covered purely electrically. Four different driving modes can be used to determine the type of drive used. Purely electric driving can be prioritized with the EV button. In this case, the combustion engine does not start until a variably noticeable pressure point in the accelerator pedal is exceeded or the battery charge level is too low. In “Battery Hold” or “Battery Charge” mode, the gasoline engine becomes the primary power source so that the existing charge status of the battery is maintained or even increased – to enable purely electric driving in the city later on, for example.

In the main “Auto Hybrid” mode, the gasoline engine and electric motor automatically share the workload: low speeds are covered solely by electric power, with the combustion engine primarily coming into play at higher speeds. Alternatively, both power units work together to drive the car: when the accelerator is pressed hard, high torque from the electric motor supports the combustion engine. When accelerating from low engine speeds, the electric motor bridges the tenths of a second that the turbocharger needs to build up pressure. When driving at a constant speed, the electric motor acts in phases as a generator, shifting the load point of the TFSI to more efficient operating ranges.

The predictive operating strategy (POS) helps with energy efficiency and energy recovery in driving mode. In “Auto Hybrid” mode, when route guidance is activated, the POS controls the powertrain so that the battery charge is intelligently distributed over the entire route. It continuously evaluates data from navigation, sensors, and the assistance systems. The POS takes real-time events such as traffic jams and heavy city traffic into account and adapts its calculations to the driving style. It uses this information to calculate a rough plan for the route. At the same time, the POS creates a detailed plan for short distances, working closely with predictive efficiency assist (PEA). The PEA uses data from onboard sensors to identify road signs, intersections, speed limits, and vehicles ahead.

The active accelerator pedal is also connected to the drive management system and provides haptic feedback to support the most efficient driving style possible. A pressure point in the pedal lets the driver know when they are leaving the purely electric driving range. Based on information from predictive efficiency assist, the pedal also signals when the driver should take their foot off the gas pedal in order to coast or recover energy. Braking maneuvers up to approximately 0.3 g – that is, the vast majority of decelerations in everyday driving – are handled by the electric motor alone, which recovers energy (regenerative braking). The hydraulic wheel brakes, supported by an electric brake booster, are only activated when the brake pedal is pressed harder. The transition is almost imperceptible and is known as “brake blending.”

PHEV models are charged at a 400-volt three-phase connection with up to 7.4 kW. The charging time at an industrial socket or Wallbox is between 2.5 and 4.5 hours. This makes it possible to charge the vehicle quickly and easily once or twice a day, either at home or at work. A full charge from a 230-volt domestic power socket takes six to eight hours, depending on the size of the battery.

The battery system consists of liquid-cooled lithium-ion cells. The power electronics, which are also integrated into the cooling circuit, convert the direct current from the high-voltage battery into three-phase current for the electric motor, while doing the opposite during regenerative braking. A sophisticated thermal management system controls both the high-temperature circuit for the combustion engine, including transmission and auxiliary units, and the low-temperature circuit for the battery, charger, electric motor, and power electronics. A heat pump is integrated into the thermal management system, in which electrical energy is converted into heat output. The heat pump is linked to the refrigerant circuit of the air conditioning system and uses the waste heat from the high-voltage components for fast and efficient temperature control of the interior.

Mild hybrid technology

Audi has also offered mild hybrid drives (mild hybrid electric vehicles, MHEV) since 2017. This technology is equally suitable for use with diesel and gasoline engines and can reduce fuel consumption in customer operation by up to 0.8 liters per 100 kilometers. Purely electric driving is not possible here.

Audi offers two versions of the MHEV drive systems. The four-cylinder engines are based on the familiar 12-volt electrical system. The six- and eight-cylinder engines are equipped with a 48-volt system, which serves as the main electrical system. A compact lithium-ion battery stores the energy. A water-cooled belt-driven alternator starter (BAS) is located at the front of the combustion engine and is connected to the crankshaft via a heavy-duty V-ribbed belt. During deceleration, the BAS can recuperate up to 8 kW of power and feed the energy back into the battery. A DC/DC transformer connects the 48-volt system to the 12-volt onboard electrical system.

The 48-volt MHEV technology is particularly convenient and efficient. If the driver takes their foot off the accelerator at speeds between 55 and 160 km/h, the car can coast for up to 40 seconds with the engine completely switched off or, optionally, recover energy. At low speeds, the start-stop phase begins at 22 km/h. The drive management system uses navigation data and onboard sensors to decide in each situation whether coasting or regenerative braking is more efficient. For example, it selects regenerative braking when efficiency assist detects a vehicle ahead. During braking phases, the BAS assists with deceleration and can feed the recovered electrical energy into the 48-volt storage system or use it directly for electrical components.

When the accelerator is pressed again after a coasting phase or a stop, the combustion engine is restarted via the BAS. The conventional pinion starter is only used for the first start, when the engine oil is still cold and a higher starting torque is required.

The BAS start is modulated according to the driver’s requirements. For example, if the air conditioning system requires the engine to be started when the vehicle is stationary, this is done in a particularly comfortable manner. The same applies when the brake is released during a start/stop phase in order to keep up with traffic. If the accelerator is pressed further, signaling a clear desire to accelerate, the start is executed as quickly as possible. There is also what is known as predictive comfort start: here, the engine starts as soon as the car in front begins moving, even if the brake is still pressed.

The operating principle of MHEV technology is the same for the 12-volt electrical system as it is for 48 volts. However, the coasting phases, regenerative braking performance, and CO2 savings are slightly lower (with the 12-volt system).

Cylinder on demand

The cylinder on demand (COD) efficiency system is a cylinder deactivation system. Audi currently uses it in two engines – the 1.4 TFSI and the 4.0 TFSI. At low to medium loads and engine speeds, the system deactivates half of the cylinders in the upper gears: the four-cylinder engine runs as a two-cylinder engine in COD mode, while in the V8, one cylinder bank – that is, half of the cylinders – is temporarily shut down.

The COD system switches off the fuel injection and ignition and also closes the valves.

The switchover process takes only milliseconds and is practically imperceptible. In the active cylinders, operating points shift to higher loads, which increases efficiency, while the deactivated cylinders continue to move almost loss-free like a gas spring under low pressure. When the driver steps on the accelerator, the deactivated cylinders are reactivated. The COD system can reduce actual fuel consumption by several tenths of a liter per 100 kilometers.

S tronic dual-clutch transmission

The S tronic dual-clutch transmission combines the comfort of an automatic with the efficiency of a manual gearbox. It is available in various versions – with six and seven gears – across a wide range of models.

Audi has developed its own version of the seven-speed S tronic for the longitudinally mounted engines. In this version, the gearwheels for all speeds are arranged one behind the other on an output shaft. The four variants for the transverse-mounted engines, on the other hand, are designed in a layout with two output shafts. It allows for a compact design.

Which variant is used with which engine depends on the customer’s vehicle preferences and the torque that needs to be transmitted.

Two multi-plate clutches are integrated into the S tronic, which operate different gears. Clutch C1[SC1] sends the torque via a solid shaft to the gearwheels of the odd gears 1, 3, 5, and 7. A hollow shaft rotates around the solid shaft. It is connected to clutch C2, which is either parallel to C1 or located inside it. This C2 operates the gearwheels of the even gears 2, 4, and 6 as well as the reverse gear. Both sub-transmissions are permanently active, but only one is connected to the engine. For example, when accelerating in third gear, fourth gear is already engaged in the second sub-transmission. The shift is achieved by changing the clutches – C1 opens while C2 closes. This process takes only a few hundredths of a second and occurs with almost no interruption in traction. The S tronic shifts so dynamically, smoothly, and comfortably that the gear change is barely noticeable.

The mechatronics module, a compact and robust block, combines the electronics with the hydraulic actuators. Its control concept allows the speed of the gear change to be varied and the required power to be precisely regulated. The multi-plate clutches are managed with maximum precision – the seven-speed S tronic operates with great fineness even in stop-and-go traffic and when maneuvering.

The seven-speed S tronic can be used in different ways. Automatic mode offers the D (Drive) and S (Sport) programs. Drivers can shift gears themselves using the selector lever or with the paddles on the steering wheel. Another feature for high-performance models is Launch Control, which fully exploits the vehicle’s acceleration potential when starting. The sportiest seven-speed S tronic for longitudinal engines can handle speeds of up to 9,000 rpm.

In all variants, the S tronic offers many strengths: high efficiency, intelligent management, and a wide spread with long ratios in the higher gears. In many cases, the high-tech transmission reduces fuel consumption compared to a manual gearbox. Its two dry clutches do not require their own oil supply, which further increases efficiency. All S tronic variants are combined with the Audi start-stop system. In addition to an innovative pressure accumulator system, the longitudinally mounted S tronic features shift-by-wire technology, which is a prerequisite for numerous assistance systems, including piloted driving.

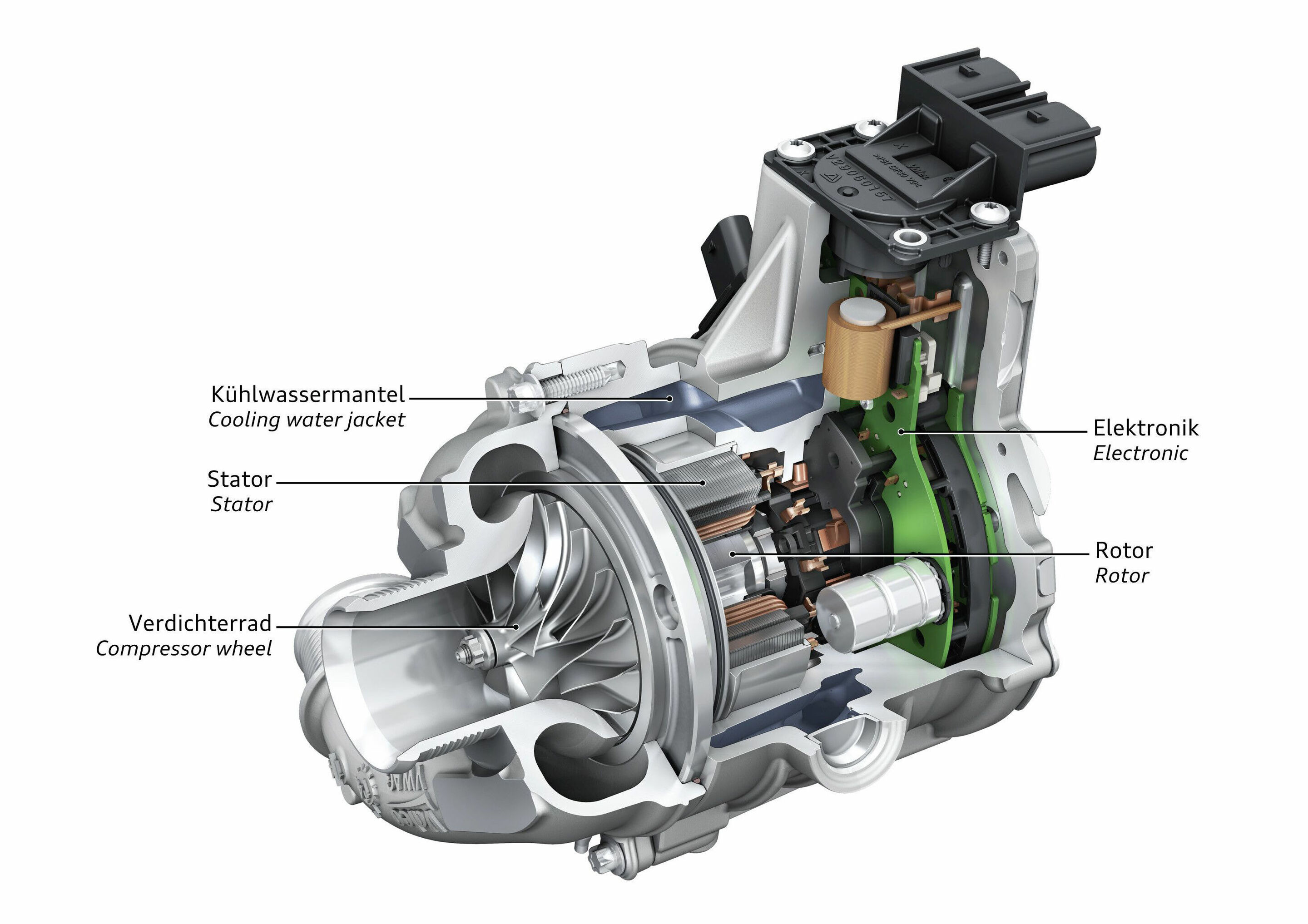

Electrically powered compressor

The electrically powered compressor (EPC) supplements the turbocharger’s work when starting off and accelerating at very low engine speeds – in other words, whenever there is too little energy in the exhaust flow for powerful torque build-up. This enables a spontaneous response and dynamic performance when starting from a standstill. Sporty drivers appreciate the overtaking power and spontaneous power delivery when pulling out of corners. With a comfort-oriented driving style, EPC technology avoids unnecessary downshifting and thus keeps the engine speed and fuel consumption low.

The EPC operates on a 48-volt system. It is located in the intake path behind the intercooler and becomes active in the following two operating states: When starting, the bypass closes and the EPC pre-compresses the air flow. This increases the filling of the combustion chamber. When driving, if the load demand from the accelerator is high and the energy supply in the exhaust gas is low, the bypass valve closes – the intake air then flows into the EPC, where it is compressed a second time. A compact electric motor with an output of up to 7 kW accelerates the EPC’s compressor wheel to up to 70,000 rpm in approximately 250 milliseconds.

quattro permanent all-wheel drive

Across its model range, Audi offers different vehicle concepts – and the quattro technology is just as versatile.

Modular longitudinal matrix: the self-locking center differential

In Audi models with a longitudinally installed front engine, the self-locking center differential is the heart of the quattro drive. It is designed as a purely mechanical planetary gear set that operates without delay. A ring gear encloses a sun gear. Between them rotate cylindrical planet gears, which are connected to the rotating housing. In normal driving conditions, 60 percent of the drive torque flows through the ring gear, which has a larger diameter, and via its connected output shaft to the rear axle. Forty percent goes through the smaller sun gear to the front axle. This asymmetrical, dynamic torque distribution results in sporty, rear-biased handling. Axial forces are generated by helical gears as soon as torque is transmitted through the differential. These forces create a locking torque via friction plates, directing power to the wheels with better traction.

In its latest configuration, the center differential can transfer up to 70 percent of the torque to the front axle or a maximum of 85 percent to the rear axle. The high locking values enable a clearly defined torque distribution and highly precise interaction with control systems such as the ESC and wheel-selective torque control. To further enhance driving dynamics and safety, Audi’s top models based on the modular longitudinal matrix also feature the sport differential.

Modular transverse matrix: the electrohydraulic multi-plate clutch

In compact models with transversely mounted engines, Audi uses a quattro drivetrain whose core component is a multi-plate clutch with hydraulic actuation and electronic control. For weight distribution reasons, it is mounted at the end of the cardan shaft in front of the rear-axle differential. Inside, the clutch contains a set of metal friction plates arranged in pairs, one behind the other. Each plate is firmly interlocked with the clutch drum, which rotates with the cardan shaft, while the other is connected to the shaft leading to the rear-axle differential.

The all-wheel-drive software continuously calculates the ideal torque distribution between the front and rear axles based on a wide range of data. When torque is required, the highly efficient electric axial-piston pump builds up hydraulic pressure up to 40 bar within a few milliseconds. This compresses the friction plates and transmits the drive torque to the rear axle in a continuously variable manner. The electronically controlled multi-plate clutch guarantees optimum traction, driving dynamics, and driving safety and ensures dynamic handling with actively controlled torque distribution.

In the sporty transverse-engine models, the management of the multi-plate clutch is designed with a strong focus on dynamics. The special control philosophy takes into account numerous parameters relevant to driving dynamics; in some models, it also considers the status of Audi drive select and the electronic stabilization control (ESC). The result is a more frequent and pronounced torque distribution to the rear axle, further enhancing sporty handling. In sport mode or with ESC deactivated on low-traction surfaces, the system even allows controlled drifts. Conversely, during relaxed driving, some models enable temporary, fully automated clutch disengagement to save fuel. As soon as driving conditions change, the quattro drive reactivates.

quattro with ultra technology

quattro with ultra technology combines driving dynamics and safety with high efficiency. This is made possible by the interplay of all-wheel-drive components with a sophisticated operating strategy and torque distribution perfectly tailored to the vehicle. The optimized all-wheel drive engages only when needed. Yet it delivers traction and driving dynamics indistinguishable from permanent systems.

When driving at a moderate pace, quattro with ultra technology utilizes all the advantages of front-wheel drive. However, the all-wheel drive remains permanently available and is ready to activate instantly when required. Control of the quattro drivetrain is fully connected. It records and evaluates data such as the steering angle, lateral and longitudinal acceleration, and engine torque every ten milliseconds.

Engagement of the all-wheel drive is generally predictive, meaning proactive. For example, during fast cornering, the control unit calculates the point at which the inner front wheel will reach its grip limit. It calculates this about half a second in advance. Just before the wheel reaches this calculated limit, all-wheel drive is activated. In reactive engagement, which rarely occurs in practice, the system responds to sudden changes in traction. This happens, for example, when the wheels move from dry asphalt to a patch of ice. Thanks to the very short engagement times, full quattro performance is guaranteed even in these extreme situations.

Compared to competitors, quattro with ultra technology achieves a significant efficiency gain through its concept of two clutches in the drivetrain. When the system switches to front-wheel drive, the front clutch – a multi-plate clutch at the transmission output – disconnects the cardan shaft. At the same time, a decoupling clutch in the rear-axle transmission opens. It shuts down the rotating components that cause the most drag losses, such as the ring gear running in an oil bath. Despite these additional components, quattro with ultra technology is almost four kilograms lighter than the previous system.

quattro with ultra technology is designed for numerous Audi models with a longitudinally mounted front engine. The system is used in combination with manual transmission or the S tronic dual-clutch transmission with up to 500 Nm of torque.

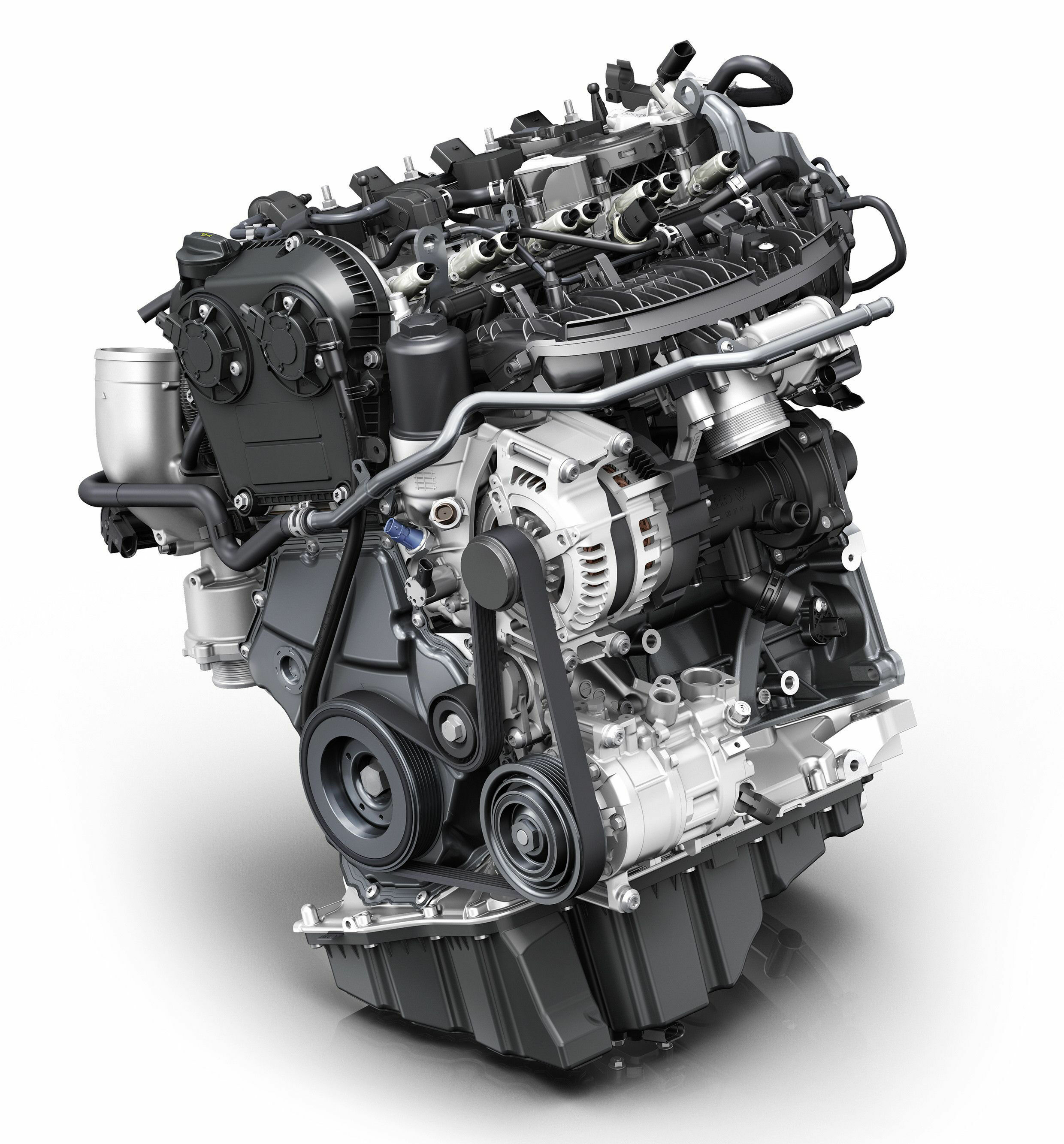

Rightsizing

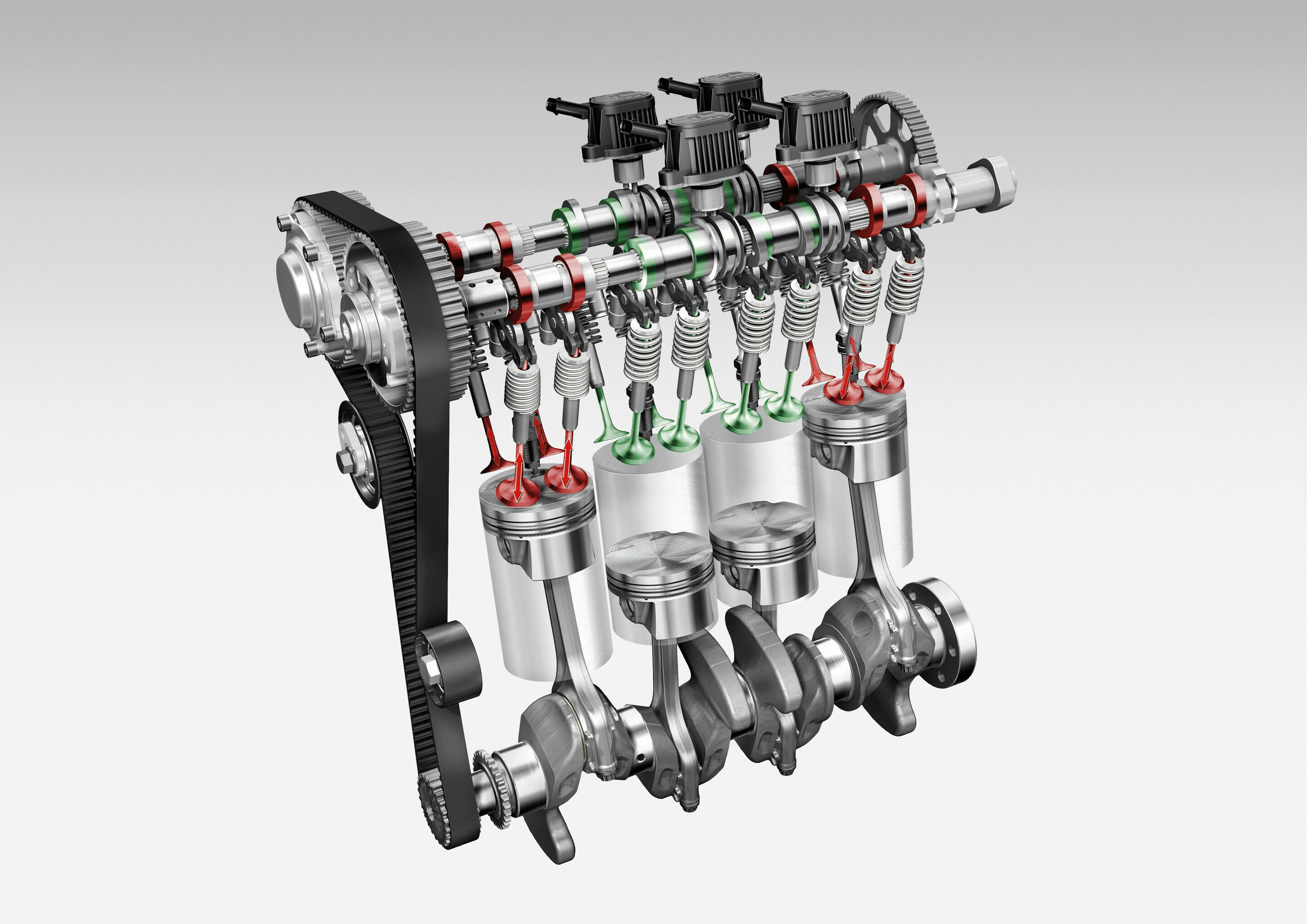

With the introduction of TFSI technology, “downsizing” – the reduction of engine displacement while simultaneously increasing power density – became mainstream in engine development. This approach enabled significant fuel savings. “Rightsizing” takes conventional downsizing a step further by optimizing the combustion process and selecting the appropriate displacement to achieve additional fuel-efficiency benefits in near-full-load conditions. Innovative technologies make this possible, such as the Audi valvelift system (AVS), the exhaust manifold integrated into the cylinder head, and the turbocharger with an electric wastegate actuator. These technologies allow engines to be designed so that displacement, power, torque, and fuel consumption are perfectly matched to the required operating conditions. The cylinder on demand (COD) system is another example. It deactivates half of the cylinders under partial load. This solution is a variant of the rightsizing strategy, which aims to balance displacement and turbocharging in the optimal ratio.

B-cycle process

The B-cycle combustion process is an efficiency technology for Audi gasoline engines. It is specially designed for the partial-load range, which is by far the predominant operating mode. Essentially, the process is comparable to the so-called Miller cycle. However, Audi has significantly advanced it – by adding higher compression, turbocharging, and the Audi valvelift system (AVS). As a result, at moderate speeds, drivers experience the fuel-saving benefits of a small-displacement engine. With a sporty driving style, they profit from the dynamics of a large engine.

The B-cycle combustion process is used in three TFSI engines: a variant of the 2.0 TFSI, the 3.0 TFSI V6, and the 2.9 TFSI V6 with its biturbo charging. The core of the combustion process is an unusually short intake valve opening duration under partial load. In the V6 TFSI, the intake valves close at just 130 degrees of crankshaft angle – well before the piston reaches bottom dead center (BDC). This, combined with increased intake manifold pressure, reduces throttling losses. The amount of fresh charge drawn in remains relatively small; when the piston moves upward after BDC, the compression phase begins correspondingly late. This allows a high geometric compression ratio of 11.2:1 in the 3.0 TFSI – the combustion occurs in a relatively small chamber volume. Compared to the short compression phase, the expansion phase is significantly extended. The result is higher engine work output at the same fuel consumption – in other words, a notable increase in efficiency.

In the classic Miller cycle, a reduced cylinder charge leads to losses in torque and power. Audi offsets these losses with turbocharging and the two-stage Audi valvelift system (AVS). At higher loads and engine speeds, the AVS in the V6 TFSI closes the intake valves later – the opening duration extends to 180 degrees of crankshaft angle in the 3.0 TFSI and 200 degrees in the 2.9 TFSI. At the same time, valve lift increases from 6.0 to 10 millimeters. Cylinder filling rises significantly – the engine revs up powerfully and delivers impressive performance.

In V6 engines, the central position of the injector in the combustion chamber is an important part of the B-cycle combustion process: it enables a geometry around the intake valves that, together with the inlet ducts, creates targeted swirl in the gas charge and thus optimizes combustion.

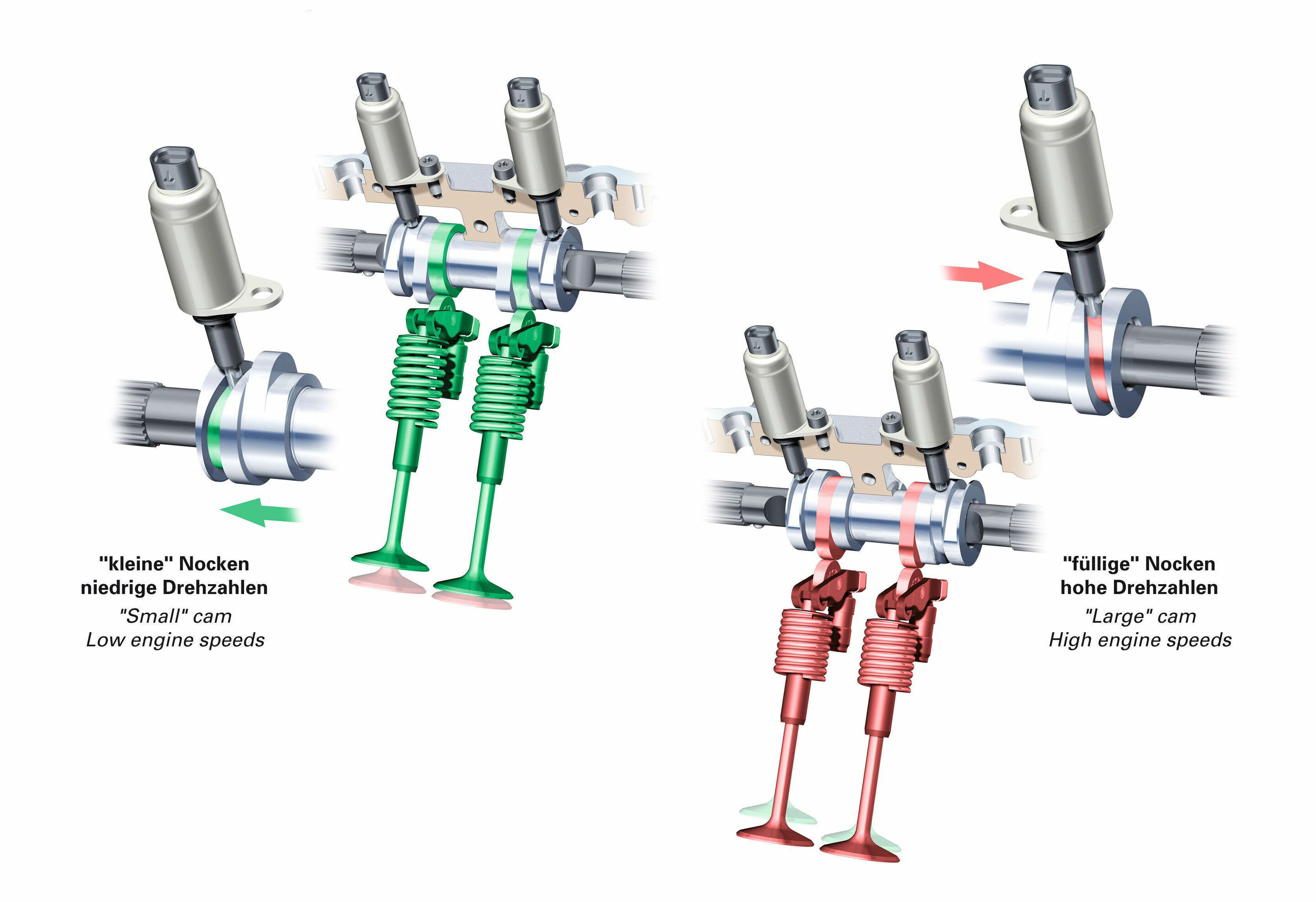

Audi valvelift system (AVS)

purposes depending on the engine, but the operating principle is always the same: The camshafts are fitted with sleeves that carry cam profiles with different contours. Electromagnetically actuated pins shift the sleeves by a few millimeters. Depending on the sleeve’s position, either the low-profile cam or the high-profile cam opens the valve.

In the 3.0 TFSI, the 2.9 TFSI, and the 2.0 TFSI with 140 kW (190 PS), the AVS acts on the intake valves. It switches their lift and opening duration in two stages depending on load and engine speed, thereby controlling the amount of air drawn in. At partial load, the lift and opening duration are relatively short. The throttle valve can remain wide open, which largely eliminates throttling losses. At higher loads, the AVS provides greater lift and later closing. The filling increases, the engine can breathe freely and delivers more power and torque.

In some four-cylinder gasoline engines and in the 2.5 TFSI with its five cylinders, the AVS varies the lift of the exhaust valves. This reduces scavenging losses in the combustion chamber and enables an optimum flow of exhaust gas to the turbocharger, especially at low engine speeds. The result is dynamic responsiveness and an increase in torque.

In the 1.4 TFSI, the system serves to deactivate half of the cylinders during moderate driving (cylinder on demand, COD).

The 4.0 TDI showcases another variant of the technology – here, the Audi valvelift system manages the two turbochargers, which operate according to the sequential turbocharging principle. The exhaust gases that each cylinder releases from its two exhaust valves flow through separate channels; each channel system feeds one of the two turbochargers. At low load and speed, the AVS keeps one valve closed so that the full exhaust flow reaches the so-called active turbocharger. When the engine speed increases, it opens the second exhaust valve and thereby activates the second turbocharger. Additional AVS units are located on the intake camshafts; they provide demand-based filling of the combustion chambers.