Locally emission-free, efficient and fit for daily driving:

Audi’s formula for plug-in hybrids

- Plug-in hybrid models enable mobility with zero local emissions

- Other PHEV models to join compact and full-size car lineup this year

- Holistic mobility concept: e-tron Charging Service facilitates charging

- Clear answers to critical questions: why PHEVs are better than their reputation suggests

Audi TechFocus Newsletter #05

A conventional internal combustion engine or a fully electric powertrain? There is a third answer to this fundamental question of modern mobility: PHEV – a plug-in hybrid electric vehicle or in short: a plug-in hybrid. The combination of a conventional internal combustion engine (IC engine) and an electric motor supplied with energy from a lithium-ion battery at the rear of the vehicle enables locally emission-free driving and low overall consumption. An overview of the current Audi technologies and models.

What does the term hybrid powertrain mean and what exactly is a plug-in hybrid?

Traditionally, a powertrain is referred to as a hybrid system whenever two propulsion technologies – in other words, an IC engine and a motor and the respective energy storage system – are combined. A typical characteristic of hybrids combining an IC engine and an electric motor is that the electric motor can either be used as the sole, locally emission-free traction motor or assist the IC engine with additional boost capacity. The electric traction motor also serves as a generator for recuperation, converting kinetic energy into electrical energy and storing it in a lithium-ion battery. Today, the plug-in hybrid electric vehicle (PHEV) has become established as the most commonly used form of hybrid electric vehicle (HEV): The battery, in this case, can be charged externally, at a charging station or power outlet. The energy capacities of the batteries of plug-in hybrid electric vehicles have increased accordingly, which benefits customers by extending the car’s electrical range.

Plug-in hybrids are a complex balancing act between two powertrain worlds. What is Audi’s formula for the best total technology package?

The focus is placed on three objectives: a confident electric driving experience, easy charging management and high suitability for everyday driving. These three factors form the target triangle of PHEV development at Audi.

For one, the electric driving experience is defined by a powerful electric motor delivering up to 105 kW, depending on the model. This ensures fully electric operation across a large speed range in diverse driving situations. The sophisticated powertrain management of Audi’s plug-in hybrids provides the basis for frequent and sustained electric driving. The smart powertrain management system controls the interaction of the electric motor and the IC engine. It decides when the car will operate in fully electric mode, when energy is recuperated or when the car coasts while the IC engine is inactivated and when the IC engine is additionally activated. The utilization of diverse vehicle sensors, route data and route information for propulsion control is essential to smart powertrain management, large segments of electric driving – especially in real-life operation – and high energy efficiency. Measured according to the WLTP cycle, Audi’s PHEV models achieve an electric range of up to 59 kilometers.

Charging management is the second pillar of Audi’s PHEV model development. Audi’s PHEV models in the mid-size and full-size class have a charging capacity of up to 7.4 kW, which recharges the hybrid models in approximately 2.5 hours. This charging period is ideal for the typical user pattern of PHEV customers: It makes easy and fast charging of the car possible, once or twice a day, either at home or additionally at work. But Audi has also provided for easy charging on the road: Audi’s proprietary e-tron Charging Service gives PHEV models card-based access to some 137,000 charging points in 25 European countries. In addition to the “Compact” charging system with a cable for household and industrial power outlets, the standard equipment of all PHEV models includes a Mode-3 cable with a Type-2 plug for public charging stations.

High suitability for everyday driving marks the third corner in the target triangle. Obviously, this is initially derived from the first two objectives: frequent operation in electric mode and easy charging management. Ample space, high variability and usability of Audi’s plug-in hybrids are other important criteria for everyday suitability. Audi’s engineers have invested a major effort in the space-saving and compact integration of the batteries in the trunk of Audi’s PHEV models. Due to the batteries being located underneath it, the trunk floor is slightly elevated compared to the conventional models, but does not include a step. This makes for a flat, effectively usable floor without impairing the customer’s ability to load the trunk. Good usability also includes the availability of a trailer hitch, except for the A8 TFSI e, and towing capacity identical to the conventional models (exception Audi Q5: conventional 2,500 kg, PHEV 1,750 kg).

The combination of an electric driving experience, easy charging and high suitability for everyday use makes plug-in hybrids an attractive choice for many customers, especially commuters, because they enable sustainable, locally emission-free driving.

What plug-in hybrids does Audi have in its current model range?

At the moment, Audi’s plug-in hybrid portfolio encompasses the A6, A7, A8, Q5 and Q7 model ranges. With the A6, A7, Q5 and Q7 PHEV models, customers can choose between a comfort-oriented variant and a version featuring a sportier configuration with higher system capacity, standard S line trim and tauter suspension and powertrain setup. With the A8, customers can select a performance variant, either with a normal wheelbase or, in the L version, with a long wheelbase.

Audi will be unveiling additional PHEV models in the coming months and subsequently offer plug-in hybrid models in eight model ranges. Other plug-in hybrid models are planned for the new Audi A3, the Q8 and Audi Q3 compact SUV.

What powertrain versions does Audi use?

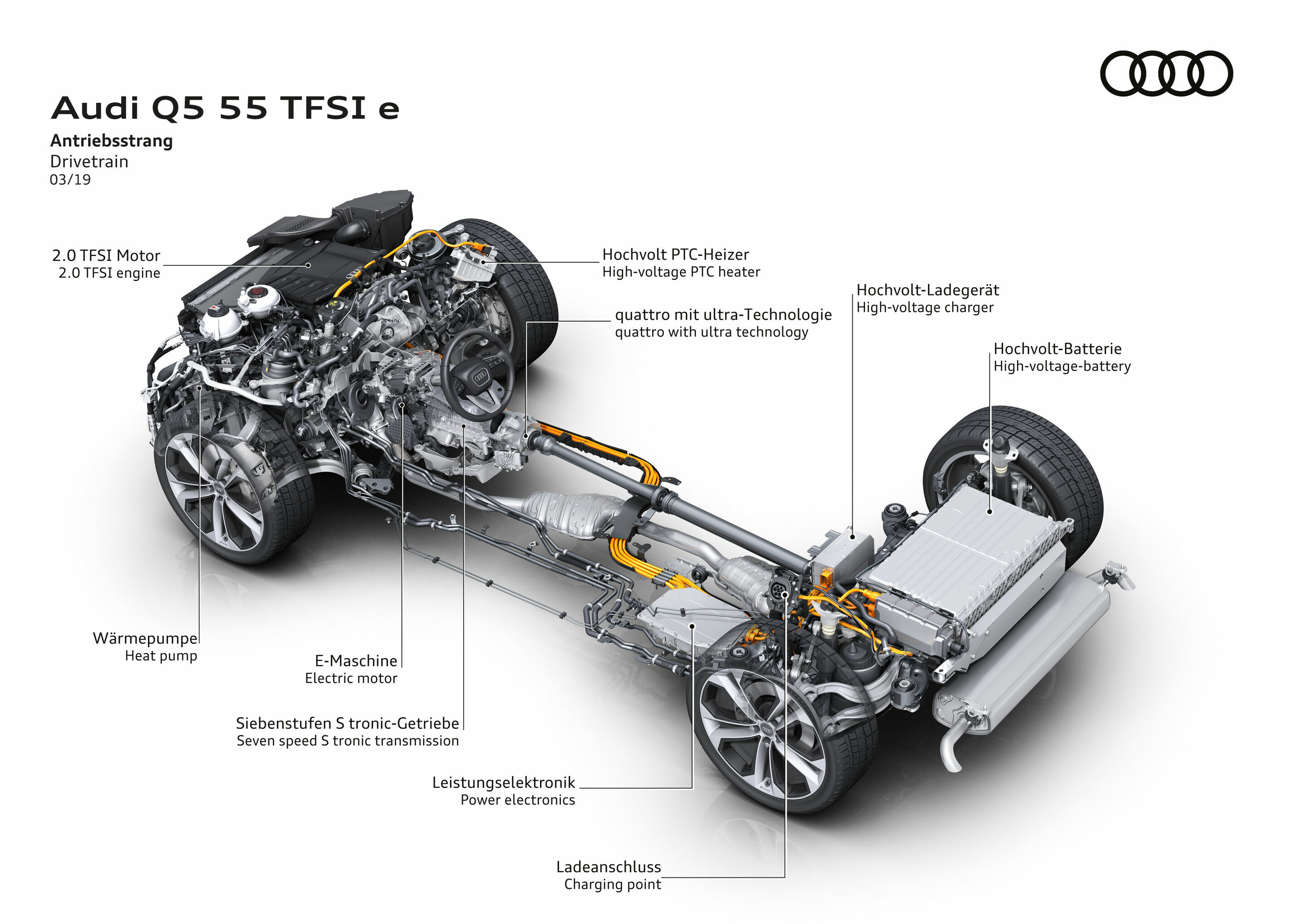

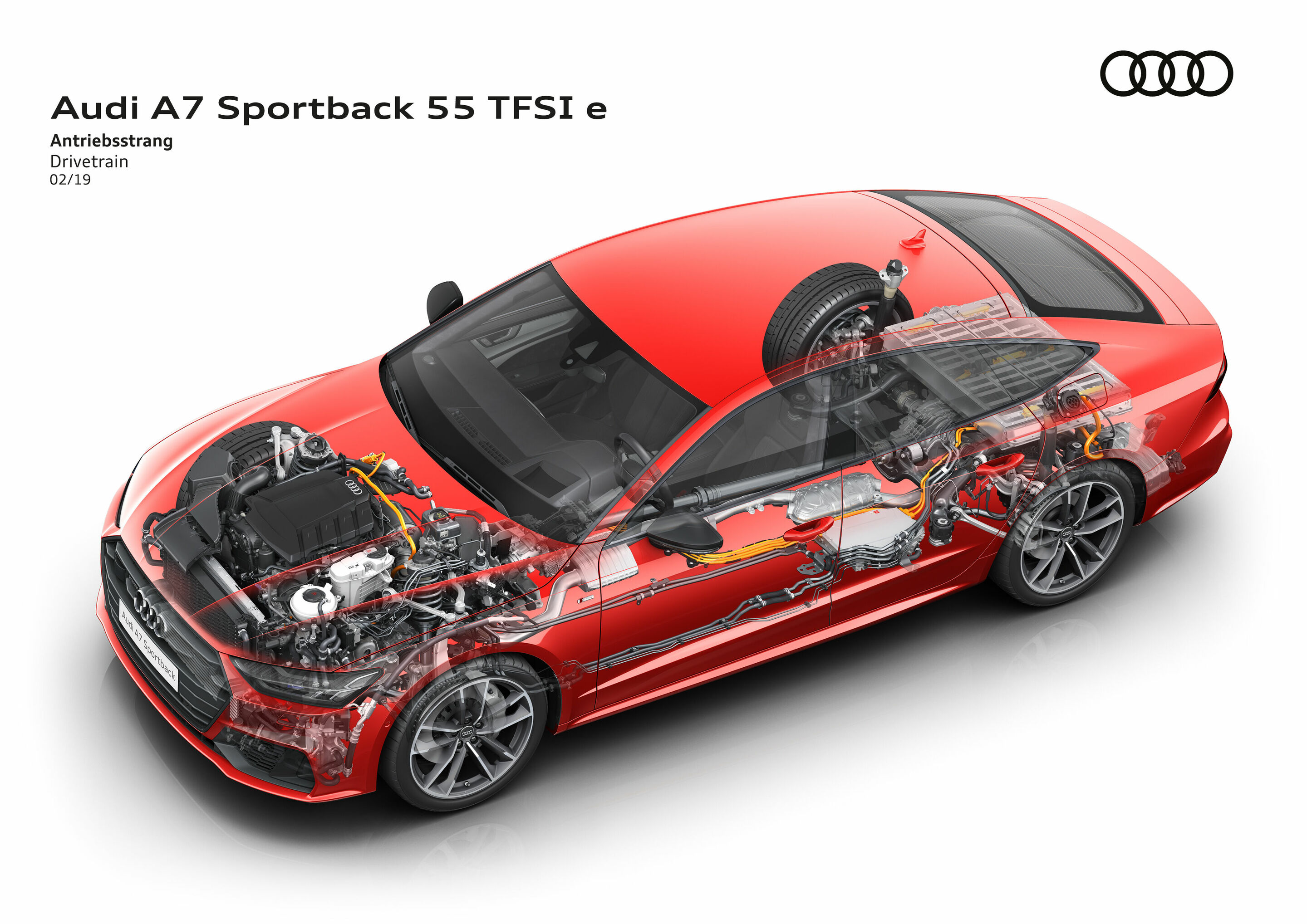

Audi combines the turbocharged direct-injection gasoline engine (TFSI) with an electric motor, whose lithium-ion battery is installed underneath the trunk floor. On all plug-in hybrid models, the electric motor of the hybrid powertrain is integrated in the transmission. The hybrid module consists of an electric motor and a decoupler connecting the TFSI engine with the drivetrain. The decoupler sits directly in front of the transmission – the Q5, A6 and A7 use a seven-speed S tronic and the Q7 and A8 an eight-speed tiptronic unit.

On all plug-in hybrids, power is transmitted via all four wheels – for maximum traction even in adverse road and weather conditions and for a high level of agility even during sporty driving. The six-cylinder models use permanent quattro drive as standard equipment, the four-cylinder models quattro ultra drive. The system output is 270 kW (367 hp) for the four-cylinder versions (A6, A7, Q5) and 335 kW (456 hp) for the six-cylinder variants (Q7, A8). For the European markets, the A6, A7 and Q5 models are additionally available as another version: in this case, the combined system output delivered by the 2.0 TFSI gasoline engine and the electric motor amounts to 220 kW (299 hp).

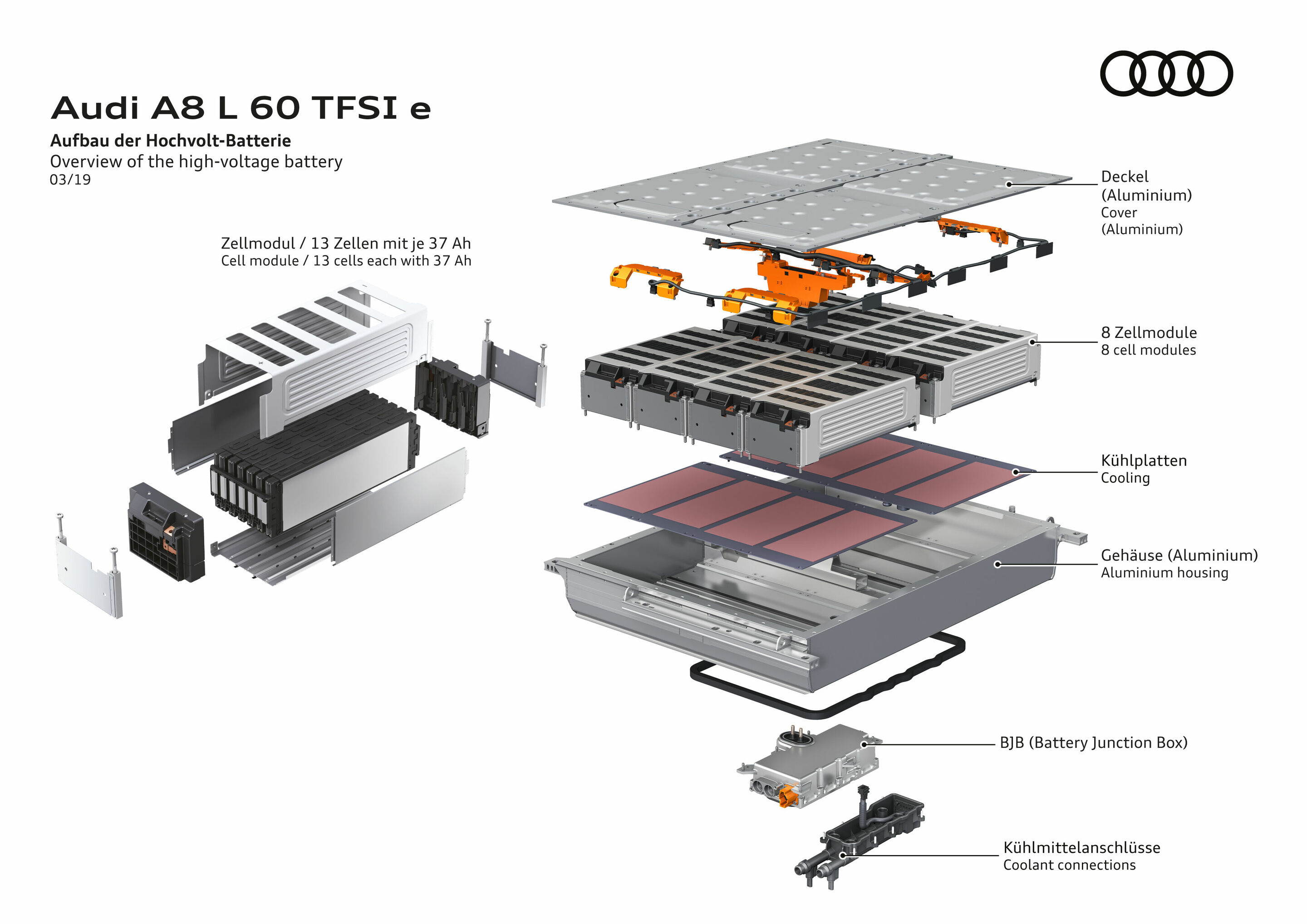

What battery technology does Audi use in the PHEV models?

The current powering the electric motors is supplied by a battery system with liquid-cooled lithium-ion cells that sits underneath the trunk floor. On all mid-size and full-size models, the 385-volt battery stores 14.1 kWh and 17.3 kWh on the Q7. On the A6, A7 and A8, it is made up of 104 so-called pouch cells consolidated in eight modules. The lithium-ion battery in the Q5 consists of prismatic cells. The cooling circuit of the battery is integrated in the low-temperature circuit supplying the electric motor and power electronics. The power electronics system transforms the direct current of the high-voltage battery into three-phase alternating current for the electric motor. In recuperation mode, the process is reversed.

How long does it take to charge the PHEV models?

Powertrain management: how does the driver select the available driving modes?

Connected to a 400-volt three phase AC charger with a capacity of 7.4 kW, it takes around two-and-a half hours to fully charge the 14.1-kWh battery that is installed in most models. On a 230-volt household outlet, about six-and-a-half hours.

The hybrid management system of the plug-in models is designed for maximum efficiency and customer comfort and automatically selects the optimal operating strategy. Three operating modes are available to the driver: In addition to the “Auto” hybrid operating mode, which is standard during active route guidance, the driver can choose between the “EV” and “Hold” modes. In “EV” mode, the vehicle is exclusively propelled by electric power as long as the driver does not exceed a variably perceptible pressure point in the accelerator pedal. “EV” mode is the default setting whenever the vehicle is started. In “Hold” mode, the powertrain management system controls the powertrain so that the existing charge status of the battery is maintained, for instance to enable subsequent fully electric driving in urban areas. Even so, this mode also includes all-electric driving segments.

Furthermore, the driver can use the commonly known switch of the Audi drive select driving dynamics system to alternate between “comfort,” “efficiency,” “auto” and “dynamic” modes and thus influence the setup of the powertrain, suspension and steering systems. During acceleration, depending on the setting, the thresholds change at which both propulsion systems work together or the electric motor provides boost and thus maximum torque. In “dynamic” mode, the electric motor increasingly assists the IC engine with its electric boost capacity for maximum driving dynamics.

How does powertrain management of Audi PHEV models work?

Less is more. For long electric driving stages of its PHEV models, Audi relies on the interaction between the right battery size and sophisticated powertrain management, which, due to its high efficiency and recuperation capacity, eliminates the need for larger batteries.The Predictive Efficiency Assistant (PEA) and the Predictive Operating Strategy (POS) are the technological centerpieces of the PHEV models. Both systems serve the purpose of maximizing the efficiency of using the electrical energy stored in the lithium-ion battery by means of predictive propulsion and recuperation management and feeding a large amount of kinetic energy back into the battery.

The Predictive Efficiency Assistant – known from the conventional models – situationally controls the propulsion and recuperation behavior to suit immediate and obvious parameters of the predictive route data such as upcoming city-limit signs, intersections, traffic circles, the topography with bends in the road, uphill and downhill sections, known speed limits as well as preceding vehicles captured by the radar sensor. The assistant informs drivers by displaying relevant information and with a haptic impulse at the accelerator pedal reminds them to lift.

The Predictive Operating Strategy controls the propulsion and recuperation behavior along the entire route plan. During active route guidance, the POS analyzes the navigation data, the information supplied by the Predictive Efficiency Assistant and the vehicle sensors. Based on this analysis, it prepares a rough plan for the entire route and a detailed plan for the next kilometers ahead. The driver receives information when it is time to lift. Concurrently, predictive recuperation is initiated. Route planning serves the purpose of maximizing electric driving in urban areas in order to arrive at the destination with a near-empty battery. The reason is that as much electric energy as possible should be used in order to recharge the vehicle at the destination.

What is an active accelerator pedal?

By providing haptic feedback, the active accelerator pedal assists drivers in maximizing the efficiency of their driving style. Via a pressure point in the accelerator pedal, it indicates to them when they are leaving the all-electric driving range. Based on the information from the Predictive Efficiency Assistant, it also prompts the driver to lift for coasting or recuperation.

The propulsion strategy is designed to provide drivers with a highly varied driving experience: characterized by maximum efficiency and a high proportion of electric driving on the one hand and – as needed – very sporty driving due to boosting on the other. The electric motor assists the IC engine in this process and the level of assistance depends on the driving program selected. Depending on the model and motor configuration, a maximum of 500 Nm (Q5, A7) or 700 Nm (Q7, A8) are applied – up to 200 Nm more than the respective TFSI develops on its own.

In the “S” transmission mode, which is preselected in the “dynamic” drive select profile, the electric motor basically remains active and recuperates during deceleration. In the case of the other settings, in interaction with the Predictive Efficiency Assistant, deceleration recuperation is always used when it makes more energetic sense than coasting. Deceleration recuperation ranges up to about 0.1 g and feeds as much as 25 kW back into the lithium-ion battery.

How does recuperation work?

What is the role of thermal management?

In terms of recuperation, the powertrain system of the PHEV resembles that of the new, fully electric Audi e-tron. It is designed for high efficiency and maximum recuperation capacity. During braking events, Audi’s PHEV models recuperate up to 80 kW. The electric motor handles all minor decelerations – in other words, the majority of braking events in everyday driving. In moderate braking events, it shares deceleration duties with the hydraulic wheel brakes, which are used alone only beyond a deceleration level of 0.4 g. A complex vehicle setup results in a nearly imperceptible transition between the generator brake of the electric motor and the conventional wheel brake (“blending”), combined with a carefully defined and constantly identical pressure point in the brake pedal.

The complex thermal management system is decisive for achieving long electric range and for fast interior heating. A high-temperature circuit cools the TFSI engine, its accessories and the transmission. A low-temperature circuit cools the battery, the battery charger, the electric motor and the power electronics system. A heat pump integrated in the thermal management system generates up to three kW of heat out of one kW of electrical energy. For this purpose, it is linked to the coolant circuit of the air conditioning system and uses the waste heat of the high-voltage components to heat the car’s interior.

Part-time EVs with full-time benefits: why plug-in hybrids are better than their reputation suggests

What does boosting mean?

What digital opportunities does the myAudi app open up with PHEV models?

More information

The myAudi app is a practical tool for handling the car. It transmits services from the Audi connect portfolio to smartphones. Using the app, the customer can perform remote queries of the battery and range status, start charging processes, program the charging timer and access charging and consumption statistics. Even before starting to drive, customers can air condition their cars by means of the app.

How does Audi provide green electric power?

Audi customers can supply their homes and garages using “Volkswagen Naturstrom,” 100 percent of which is produced from renewable sources such as hydroelectric power stations. Its origin is certified by TÜV on an annual basis. In addition, if required, Audi will support its customers in contracting electricians to install a suitable charging solution in their garages at home. As a result, Audi provides customers with a comprehensive mobility offering.