incampus

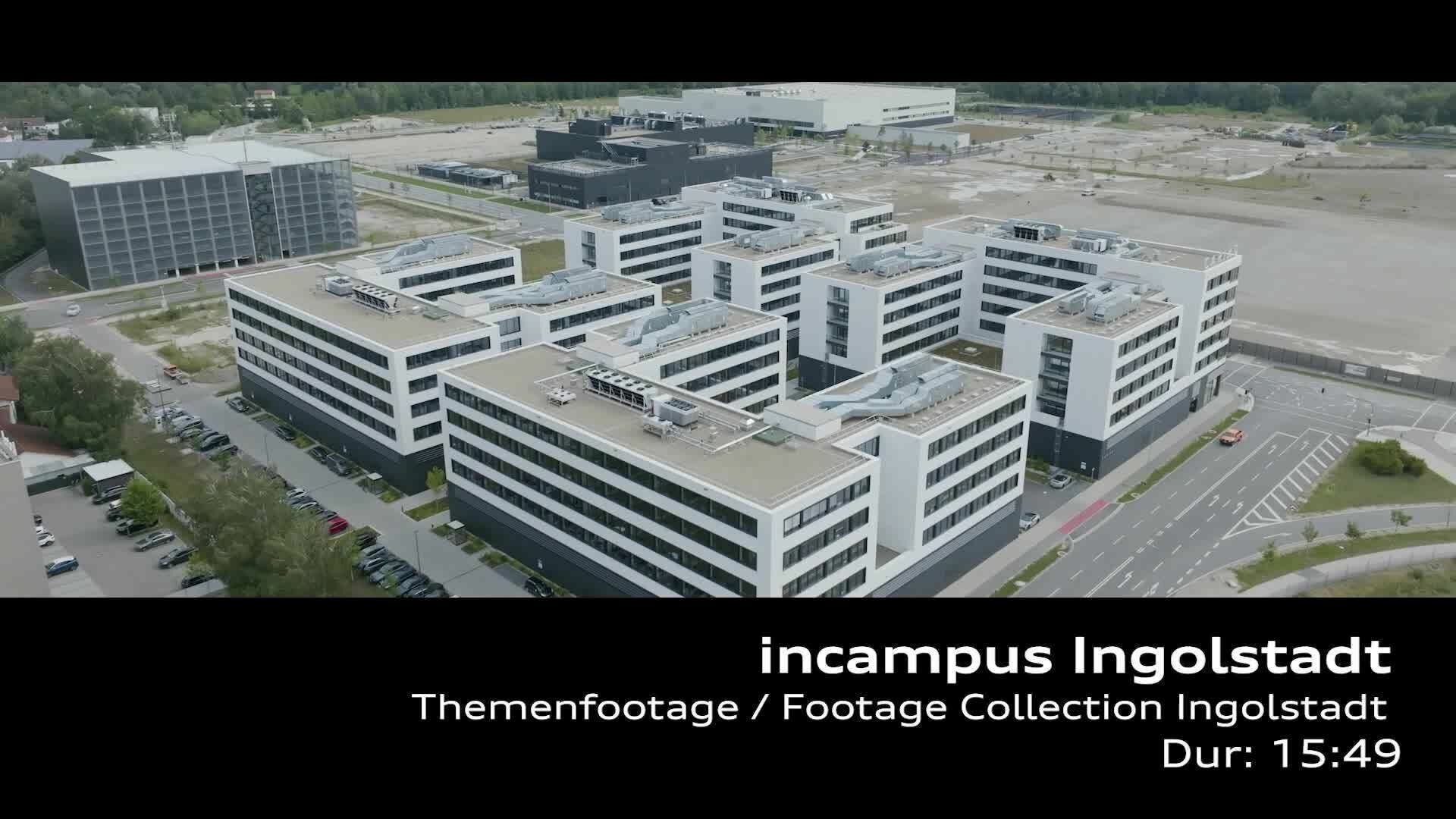

Back to overviewAudi is building for the future. incampus GmbH, a joint venture of the city of Ingolstadt and Audi AG, is investing in a campus with a focus on the technologies of the future. Audi’s vehicle safety center and a datacenter are found here, along with facilities from the VW software division CARIAD. The incampus is being built near the main factory in Ingolstadt on 75 hectares of remediated land. The collaboration between the public sector and Audi on the incampus project is an exemplary story of transformation.

The incampus is being built on a former refinery site in Ingolstadt. IN-Campus GmbH, a joint venture of the city of Ingolstadt’s holding company IFG AöR and AUDI AG, bought most of this industrial wasteland in 2015. The necessary remediation of the soil and groundwater began north of the grounds in the fall of 2016 and was structurally completed in late 2021. Development started in the clean and remediated areas even while the revitalization was underway. The buildings that are currently being built in construction section 1 are slated to be finished during the course of 2023.

One essential strength of the incampus grounds is the 75 contiguous hectares of land, which is unheard of elsewhere in Ingolstadt or the region. It offers an opportunity to build a spacious, flexible, and attractive technology park where high tech and creativity converge. In the future, 60 hectares will be a commercial and industrial area that will be built in three stages. Another benefit is the location: it is situated in the southeast of Ingolstadt, right next to the A9 freeway and just a short drive from Audi's main headquarters.

Open and close to nature: the complete facility

The incampus is being planned as an open facility without fences, making it a real campus.

Audi Sportpark – the home ground of FC Ingolstadt 04 – is on its south edge, and it is adjacent to a commercial area to the west. Sparse alluvial forests spread out to the north and east along the banks of the Danube. In between is a 15-hectare greenway with a nearly natural alluvial forest with fallow grassland and willow trees as an ecological compensation area. That is how the incampus combines urban space with the calm of the Danube’s water meadows and creates an interface between high tech and nature. A parkway with green spaces runs for about one kilometer (0.6 mi.) across the incampus from north to south. At various points, this roughly 50-meter-wide (164 ft.) campus artery widens into small seating areas – a vital communication and meeting space for employees and visitors.

State-of-the-art technology: the Vehicle Safety Center

The largest building at incampus is the Vehicle Safety Center. It was opened in September of 2023. Including acceleration zones, it spans an area of 130 x 260 meters (427 x 853 ft.) around and 20 meters (66 ft.) high.

The heart of the building is what is known as the crash arena: a pillar-free 50 x 50 meter (164 x 164 ft.) area. There is a mobile crash block in the crash arena that can be moved, making it possible to conduct a wide range of highly efficient crash research. The area is crisscrossed with several crash lanes, enabling research on collisions between two vehicles and on active safety. The longest runway is 240 meters (787 ft.) long and allows researchers to conduct experiments with speeds above the usual specifications. Belt systems and airbags are being developed even more efficiently thanks to a novel coasting slide with a delay unit. The team’s work in the Vehicle Safety Center is facilitated by very modern high-speed cameras and energy-efficient LED lighting systems. A dummy lab, component test stands, workshops, and offices complete the building.

The concept, technology, and adjacent expansion areas ensure the new driving safety center meets the requirements for many years to come. This is important in light of the increasingly strict standards and regulations on the global markets and new technological challenges. Despite the rapid progress made in simulation technology, real crash tests and component tests in hardware remain essential.

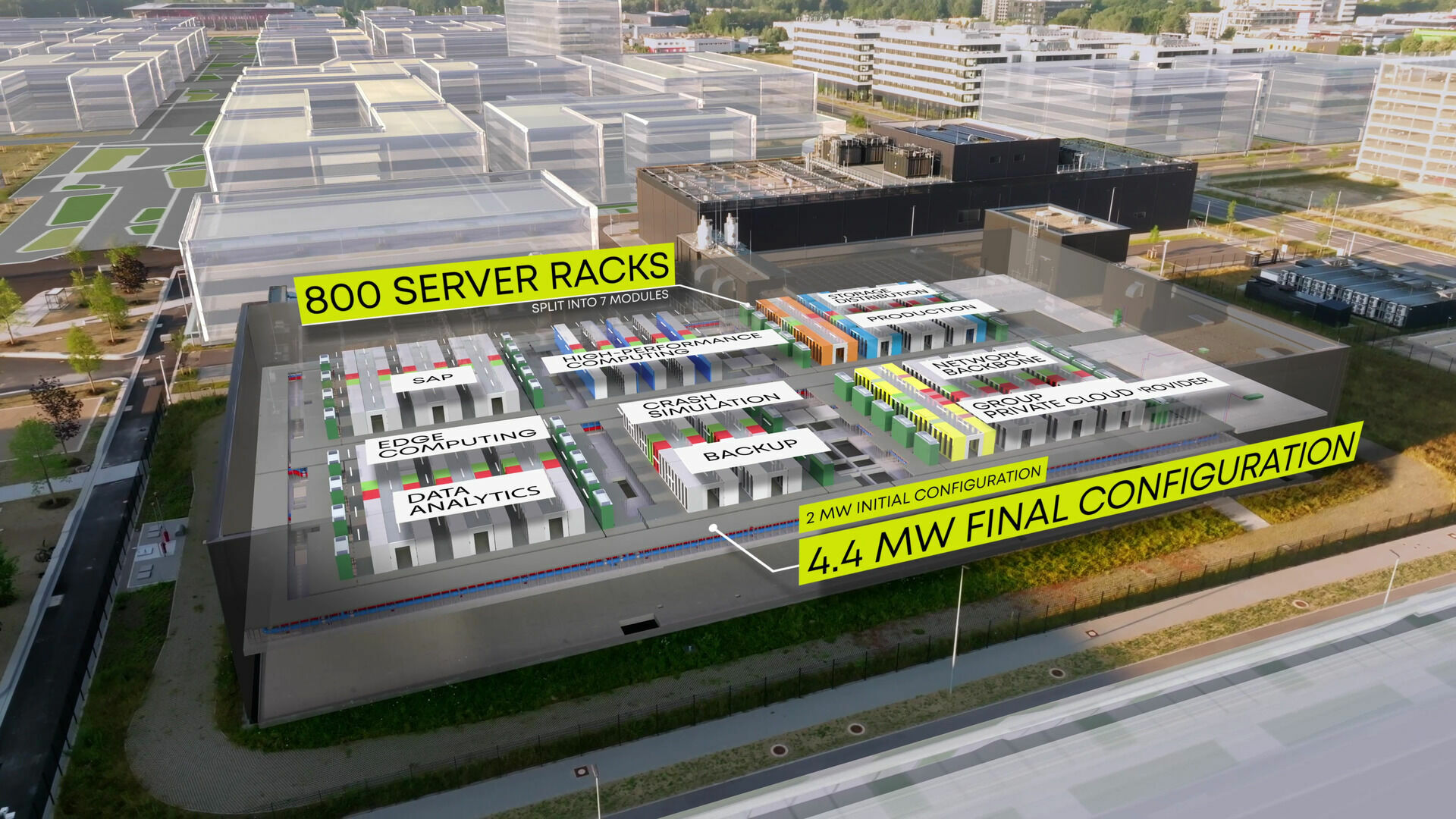

Digital nerve node: the IT Center

A new IT Center with floor space of almost 10,000 square meters (108,000 sq. ft.) was built between the project house and the Vehicle Safety Center. This will house around 8,000 servers as well as storage and network components on an area of 2,000 square meters (21,500 sq. ft.) for IT. The IT Center will support AUDI AG’s future-oriented projects with ultra-modern hardware and software; in its technical concept, maximum availability and the highest level of failure safety are given utmost importance.

Idea factory: the project house

- A key facility is known as the project house. It forms an expansive four-building complex in the northwest of the campus. It is a place where experts work on technologies of the future. The new idea factory has space for some 1,400 people. A total of 42,000 square meters (452,000 sq ft.) of office and workshop space as well as conference rooms and dining facilities are fully rented out.

- CARIAD, which pools together the Volkswagen Group’s software competencies, has had a center of competency in the incampus since late 2020. The technology park offers IT experts from the software company an attractive environment for flexible work.

- The incampus has a direct connection to the Autobahn (federal highway) A9. The A9 has functioned as a digital testing area for automated driving development for years. This testing area has now been extended to the incampus via Auwaldseestrasse.

Smart energy: the Energy Control Center

The Energy Control Center is located northeast of the project house and has begun regular operation to supply the incampus. Not only does it supply energy, it is also the heart and brain of the energy system concept for the incampus.

The LowEx network is a major element in the innovative energy system. This water-based piping network acts as a heat source and a heat sink for all the buildings on the incampus. Plastic lines with a pipe diameter of around 60 to 80 cm (24–32 in.) are already being laid in the ground of construction section 1. Buildings with a high cooling load (e.g., the IT center) release waste heat that accrues into the network, while buildings with a high heating load take the necessary energy from the LowEx network. This process turns consumers into generators. The network’s temperature intentionally shifts between 5 °C and 30 °C (41–86 °F) by taking advantage of seasonal fluctuations – this is ideal, for example, for feeding environmental heat or waste heat into the network. The necessary system temperatures are guaranteed by means of reversible heat pumps in the buildings in question.

Thermal energy storage systems in the Energy Control Center make a major contribution to load management and to increasing the energy efficiency of the overall system. With a volume capacity of around 3,000 cubic meters (105,944 cu. ft.), they save both heat and cold. The CEC (cross energy concept) system acts as the central intelligence for the energy supply. It manages the interaction of all technical components for the purpose of maximum efficiency.

The energy concept is modular and highly flexible. In construction section 1, the incampus procures electricity and long-distance heating from outside. The medium-term vision is a zero-energy campus that widely uses self-generated and regenerative energy and, to that end, integrates new innovation components again and again. This can be a photovoltaic system with a high efficiency level or an industrial fuel cell – or even technologies that are not even on the market yet.

Focus on safety: the functional building

A two-story functional building is located in the northeast of the incampus. It incorporates property protection facilities, training rooms, a dedicated fire station for the incampus, and an emergency medical center. Construction began in 2020, and it was able to go into use by August 2021.

Remediation of the former refinery grounds

incampus is being built on the site of a former refinery that was in operation for 43 years. Various petroleum products were made here from 1965 to 2008. After operation stopped, the facilities were dismantled by 2013. In the fall of 2015, IN-Campus GmbH, a joint venture of the city of Ingolstadt’s holding company IFG AöR and AUDI AG, acquired the site and signed a public-law remediation contract a few months later.

The 1,200 or so exploratory drilling operations and 50,000 laboratory analyses conducted over a number of years showed that 22 hectares were polluted and in need of remediation. The soil contained 900 metric tons of fuel oil, 200 metric tons of light gasoline, and perfluorinated and polyfluorinated chemicals (PFAS) originating from fire-fighting foam used by the former plant’s fire brigade. The necessary remediation of the soil and groundwater started in the fall of 2016. It was carried out by ARGE IN-Campus GbR, a working group made up of three specialist companies that uses ultra-modern methods. The methods used included air sparging, in which toxic substances are removed from the soil using soil vapor extraction, and honeycomb excavation with subsequent soil washing. The active remediation work was completed in late 2021. Of the extensively remediated site, 15 hectares are set aside for nature: A near-natural alluvial forest with species characteristic of local fauna is being created here as a compensation area.

Outflow protection on the incampus site, in which groundwater is pumped out of the ground from ten wells on the edge of the site, will continue until 2028. A treatment plant purifies the water to remove over 99.9% of any remaining pollutants. The remediation of the incampus site is one of the largest soil remediation projects in Germany and the first complete remediation of a refinery site in Bavaria.